MAINTENANCE OF YOUR WATER HEATER

3 Month Inspection | Replacing the Gas Valve |

At least every 3 months, a visual inspection should be made of the combustion air inlet as well as the exhaust and water piping. Check the water heater for the following:

•Obstructions, damage, or deterioration in the venting system. Make sure the exhaust and combustion air supplies are not obstructed.

•Leaking or damaged water and gas piping.

•Presence of flammable or corrosive materials in the installation area.

•Presence of combustible materials near the water

heater.

Important: Verify proper operation after servicing this water heater.

Gas Valve

The gas valve on this water heater has been permanently set at the factory for proper operation. No field adjustments are needed and none should be performed.

Removing the Gas Valve

Removal and replacement of the gas regulator valve involves the disconnection of gas piping and electrical leads. This procedure must be performed by a qualified service technician.

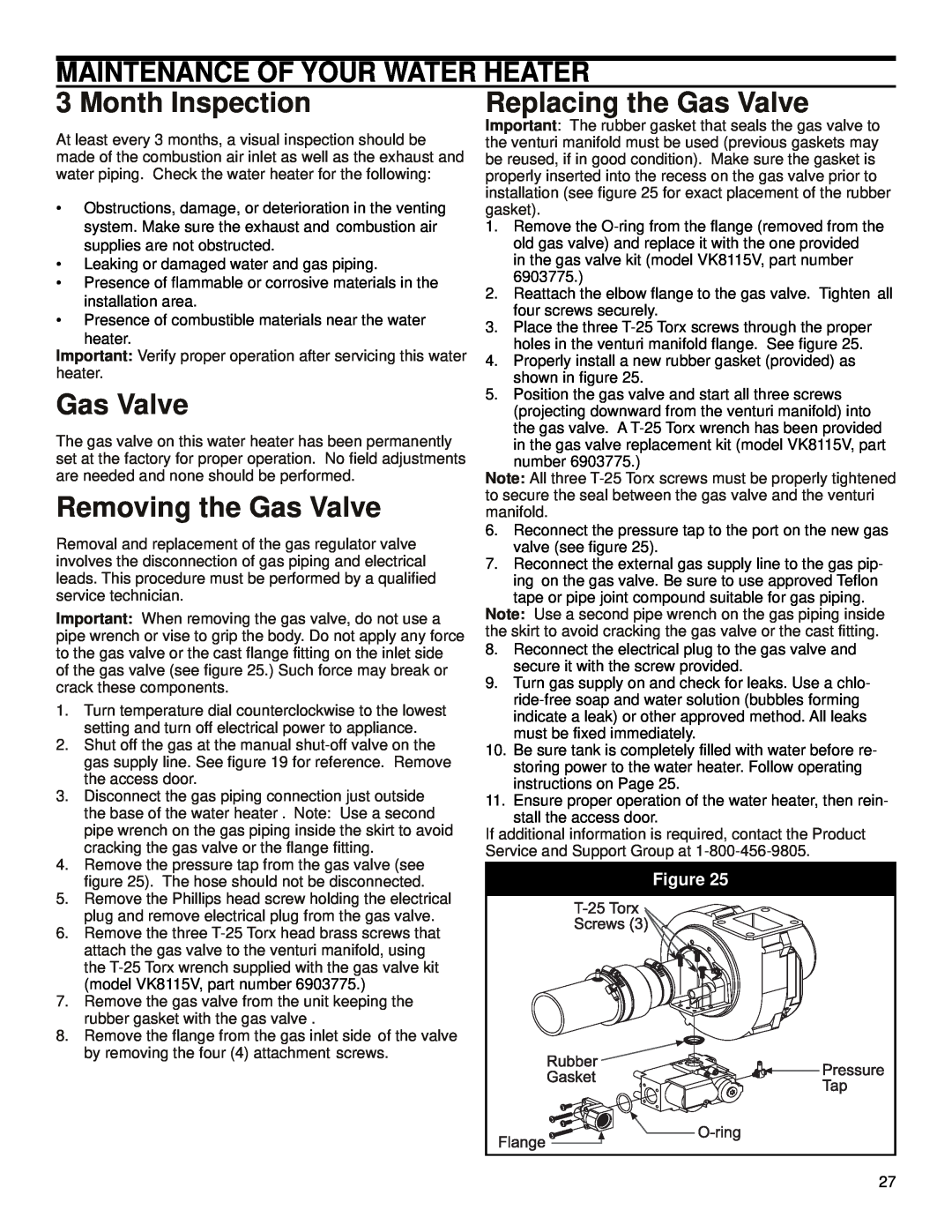

Important: When removing the gas valve, do not use a pipe wrench or vise to grip the body. Do not apply any force to the gas valve or the cast flange fitting on the inlet side of the gas valve (see figure 25.) Such force may break or crack these components.

1.Turn temperature dial counterclockwise to the lowest setting and turn off electrical power to appliance.

2.Shut off the gas at the manual

3.Disconnect the gas piping connection just outside the base of the water heater . Note: Use a second pipe wrench on the gas piping inside the skirt to avoid cracking the gas valve or the flange fitting.

4.Remove the pressure tap from the gas valve (see figure 25). The hose should not be disconnected.

5.Remove the Phillips head screw holding the electrical plug and remove electrical plug from the gas valve.

6.Remove the three

7.Remove the gas valve from the unit keeping the rubber gasket with the gas valve .

8.Remove the flange from the gas inlet side of the valve by removing the four (4) attachment screws.

Important: The rubber gasket that seals the gas valve to the venturi manifold must be used (previous gaskets may be reused, if in good condition). Make sure the gasket is properly inserted into the recess on the gas valve prior to installation (see figure 25 for exact placement of the rubber gasket).

1.Remove the

2.Reattach the elbow flange to the gas valve. Tighten all four screws securely.

3.Place the three

4.Properly install a new rubber gasket (provided) as shown in figure 25.

5.Position the gas valve and start all three screws (projecting downward from the venturi manifold) into the gas valve. A

Note: All three

6.Reconnect the pressure tap to the port on the new gas valve (see figure 25).

7.Reconnect the external gas supply line to the gas pip- ing on the gas valve. Be sure to use approved Teflon tape or pipe joint compound suitable for gas piping.

Note: Use a second pipe wrench on the gas piping inside the skirt to avoid cracking the gas valve or the cast fitting.

8.Reconnect the electrical plug to the gas valve and secure it with the screw provided.

9.Turn gas supply on and check for leaks. Use a chlo-

10.Be sure tank is completely filled with water before re- storing power to the water heater. Follow operating instructions on Page 25.

11.Ensure proper operation of the water heater, then rein- stall the access door.

If additional information is required, contact the Product Service and Support Group at

Figure 25

27 |