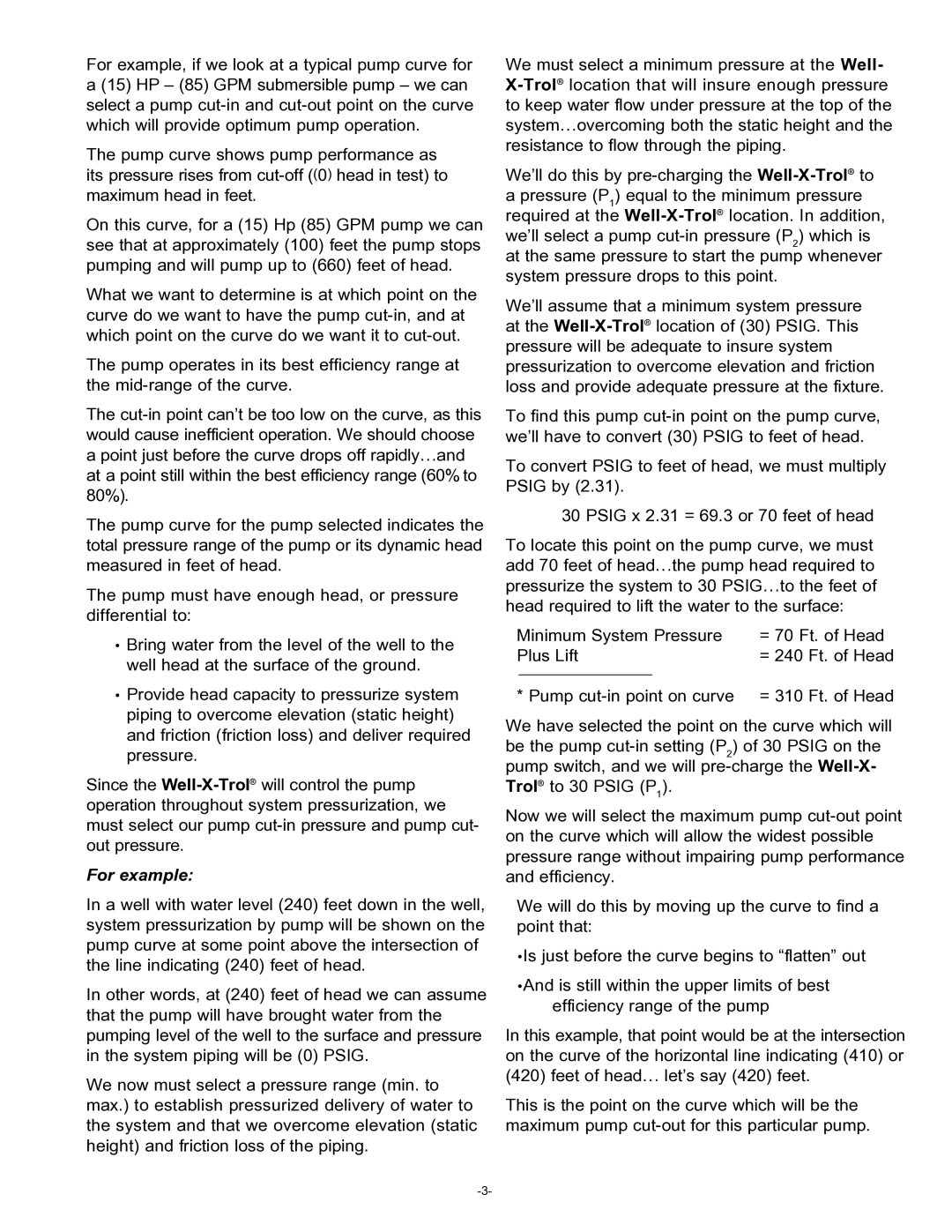

For example, if we look at a typical pump curve for a (15) HP – (85) GPM submersible pump – we can select a pump

The pump curve shows pump performance as its pressure rises from

On this curve, for a (15) Hp (85) GPM pump we can see that at approximately (100) feet the pump stops pumping and will pump up to (660) feet of head.

What we want to determine is at which point on the curve do we want to have the pump

The pump operates in its best efficiency range at the

The

The pump curve for the pump selected indicates the total pressure range of the pump or its dynamic head measured in feet of head.

The pump must have enough head, or pressure differential to:

Bring water from the level of the well to the well head at the surface of the ground.

Provide head capacity to pressurize system piping to overcome elevation (static height) and friction (friction loss) and deliver required pressure.

Since the

For example:

In a well with water level (240) feet down in the well, system pressurization by pump will be shown on the pump curve at some point above the intersection of the line indicating (240) feet of head.

In other words, at (240) feet of head we can assume that the pump will have brought water from the pumping level of the well to the surface and pressure in the system piping will be (0) PSIG.

We now must select a pressure range (min. to max.) to establish pressurized delivery of water to the system and that we overcome elevation (static height) and friction loss of the piping.

We must select a minimum pressure at the Well-

We’ll do this by

We’ll assume that a minimum system pressure at the

To find this pump

To convert PSIG to feet of head, we must multiply PSIG by (2.31).

30 PSIG x 2.31 = 69.3 or 70 feet of head

To locate this point on the pump curve, we must add 70 feet of head…the pump head required to pressurize the system to 30 PSIG…to the feet of head required to lift the water to the surface:

Minimum System Pressure | = 70 Ft. of Head | ||

Plus Lift | = 240 Ft. of Head | ||

|

|

|

|

* Pump | = 310 Ft. of Head | ||

We have selected the point on the curve which will be the pump

Now we will select the maximum pump

We will do this by moving up the curve to find a point that:

![]() Is just before the curve begins to “flatten” out

Is just before the curve begins to “flatten” out

![]() And is still within the upper limits of best efficiency range of the pump

And is still within the upper limits of best efficiency range of the pump

In this example, that point would be at the intersection on the curve of the horizontal line indicating (410) or (420) feet of head… let’s say (420) feet.

This is the point on the curve which will be the maximum pump