|

| VERTICAL CONTACT TOASTER |

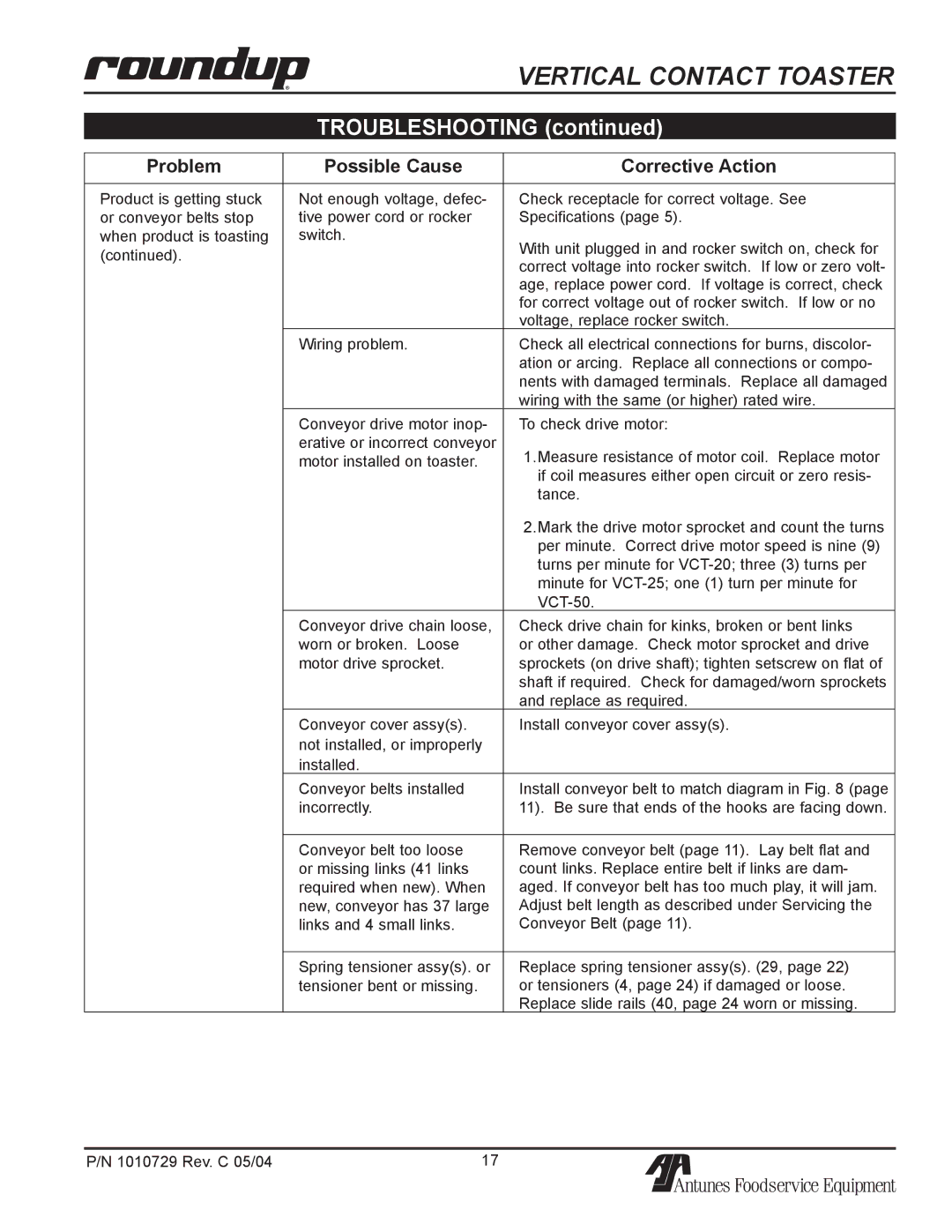

| TROUBLESHOOTING (continued) | |

|

|

|

Problem | Possible Cause | Corrective Action |

|

|

|

Product is getting stuck | Not enough voltage, defec- | Check receptacle for correct voltage. See |

or conveyor belts stop | tive power cord or rocker | Specifications (page 5). |

when product is toasting | switch. | With unit plugged in and rocker switch on, check for |

(continued). |

| |

| correct voltage into rocker switch. If low or zero volt- | |

|

| |

|

| age, replace power cord. If voltage is correct, check |

|

| for correct voltage out of rocker switch. If low or no |

|

| voltage, replace rocker switch. |

| Wiring problem. | Check all electrical connections for burns, discolor- |

|

| ation or arcing. Replace all connections or compo- |

|

| nents with damaged terminals. Replace all damaged |

|

| wiring with the same (or higher) rated wire. |

| Conveyor drive motor inop- | To check drive motor: |

| erative or incorrect conveyor | 1.Measure resistance of motor coil. Replace motor |

| motor installed on toaster. | |

|

| if coil measures either open circuit or zero resis- |

|

| tance. |

|

| 2.Mark the drive motor sprocket and count the turns |

|

| per minute. Correct drive motor speed is nine (9) |

|

| turns per minute for |

|

| minute for |

|

| |

| Conveyor drive chain loose, | Check drive chain for kinks, broken or bent links |

| worn or broken. Loose | or other damage. Check motor sprocket and drive |

| motor drive sprocket. | sprockets (on drive shaft); tighten setscrew on flat of |

|

| shaft if required. Check for damaged/worn sprockets |

|

| and replace as required. |

| Conveyor cover assy(s). | Install conveyor cover assy(s). |

| not installed, or improperly |

|

| installed. |

|

| Conveyor belts installed | Install conveyor belt to match diagram in Fig. 8 (page |

| incorrectly. | 11). Be sure that ends of the hooks are facing down. |

|

|

|

| Conveyor belt too loose | Remove conveyor belt (page 11). Lay belt flat and |

| or missing links (41 links | count links. Replace entire belt if links are dam- |

| required when new). When | aged. If conveyor belt has too much play, it will jam. |

| new, conveyor has 37 large | Adjust belt length as described under Servicing the |

| links and 4 small links. | Conveyor Belt (page 11). |

|

|

|

| Spring tensioner assy(s). or | Replace spring tensioner assy(s). (29, page 22) |

| tensioner bent or missing. | or tensioners (4, page 24) if damaged or loose. |

|

| Replace slide rails (40, page 24 worn or missing. |

P/N 1010729 Rev. C 05/04 | 17 |