VERTICAL CONTACT TOASTER

MAINTENANCE (continued)

4.Make sure the spacers are placed inside the tensioner arm. The spacers are smaller than the holes to allow the tensioner to pivot freely.

Replacing Conveyor Motor and Fan Blade

NOTE: A small amount of Loctite (Blue & Red) is required for proper gear motor installation.

1.Remove control cover.

2.Disconnect the motor wires and remove the drive motor and drive motor bracket (Figure

10). Discard the

3.Remove the motor sprocket using a hex wrench.

4.Remove the drive motor bracket from the gear motor. Save the four

5.Place one drop of Loctite (Blue) into each thread- ed hole in the gear reducer casting. Attach the drive motor bracket to the gear reducer using the original four

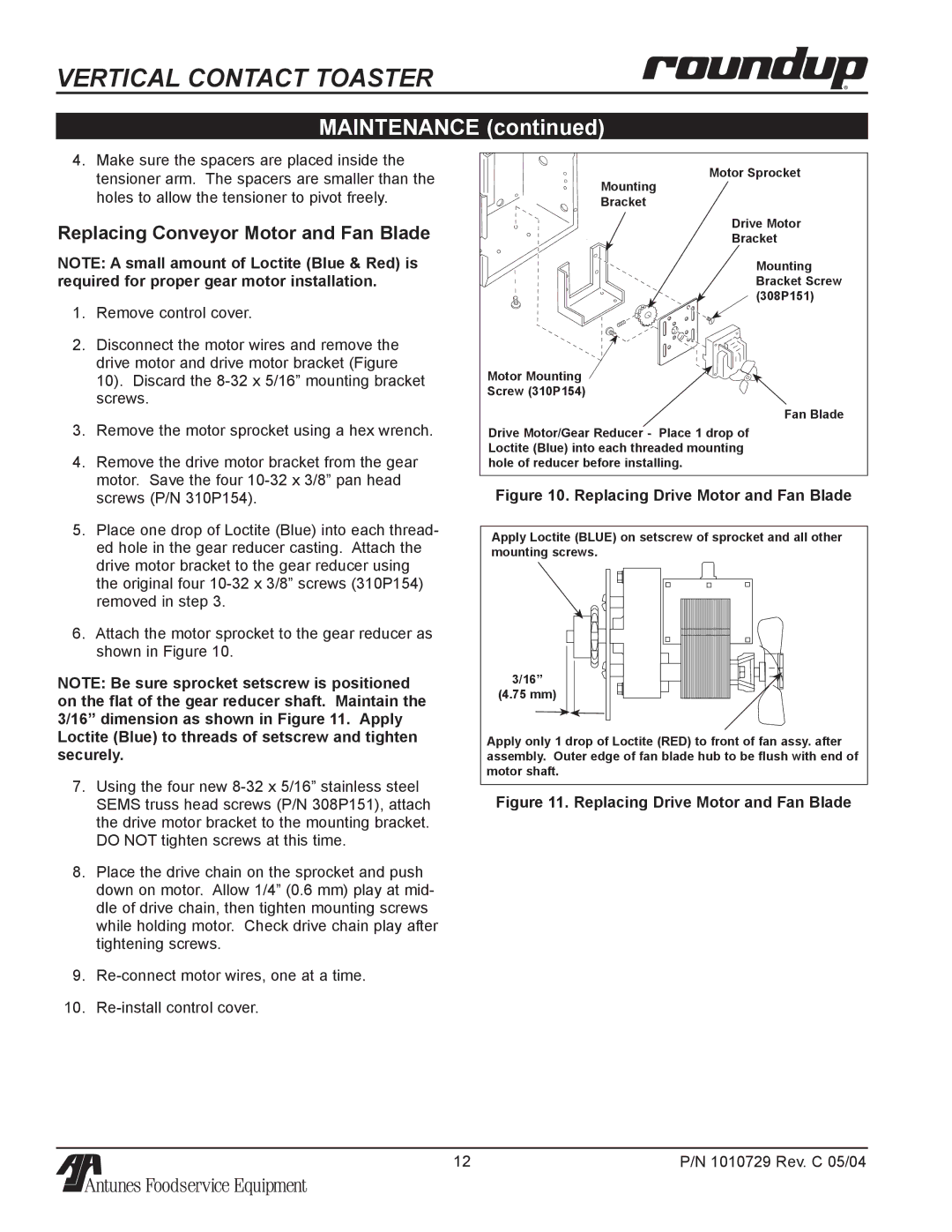

6.Attach the motor sprocket to the gear reducer as shown in Figure 10.

NOTE: Be sure sprocket setscrew is positioned on the flat of the gear reducer shaft. Maintain the 3/16” dimension as shown in Figure 11. Apply Loctite (Blue) to threads of setscrew and tighten securely.

7.Using the four new

8.Place the drive chain on the sprocket and push down on motor. Allow 1/4” (0.6 mm) play at mid- dle of drive chain, then tighten mounting screws while holding motor. Check drive chain play after tightening screws.

9.

10.

Motor Sprocket

Mounting

Bracket

Drive Motor

Bracket

Mounting Bracket Screw (308P151)

Motor Mounting  Screw (310P154)

Screw (310P154)

Fan Blade

Drive Motor/Gear Reducer - Place 1 drop of Loctite (Blue) into each threaded mounting hole of reducer before installing.

Figure 10. Replacing Drive Motor and Fan Blade

Apply Loctite (BLUE) on setscrew of sprocket and all other mounting screws.

3/16”

(4.75 mm)

Apply only 1 drop of Loctite (RED) to front of fan assy. after assembly. Outer edge of fan blade hub to be flush with end of motor shaft.

Figure 11. Replacing Drive Motor and Fan Blade

12 | P/N 1010729 Rev. C 05/04 |