VERTICAL CONTACT TOASTER

MAINTENANCE (continued)

SERVICING CONVEYOR BELTS

After a period of time, the conveyor belt links will wear and the conveyor belt will stretch. This will eventually cause the conveyor to jam as it rotates on the sprock- ets. This is easily remedied by removing one or more conveyor links from each side of the belt.

There are four 1/2” pitch links on each conveyor belt. The rest of the links are 3/4”.

1.Remove conveyor belt as described previously on page 10.

2.To shorten a stretched conveyor belt, remove one 1/2” link from the belt.

3.Reassemble the belt to the sprockets as described below.

NOTE: If the belt is too short (tight) to be reas- sembled, remove an additional 1/2” link and install a 3/4” link. This will make the conveyor belt 1/4” shorter and enable it to be reassembled.

IMPORTANT: This is not covered under warranty. It is a user responsibility.

REPLACING CONVEYOR BELTS

1.Remove old conveyor belt as described previ- ously on page 10.

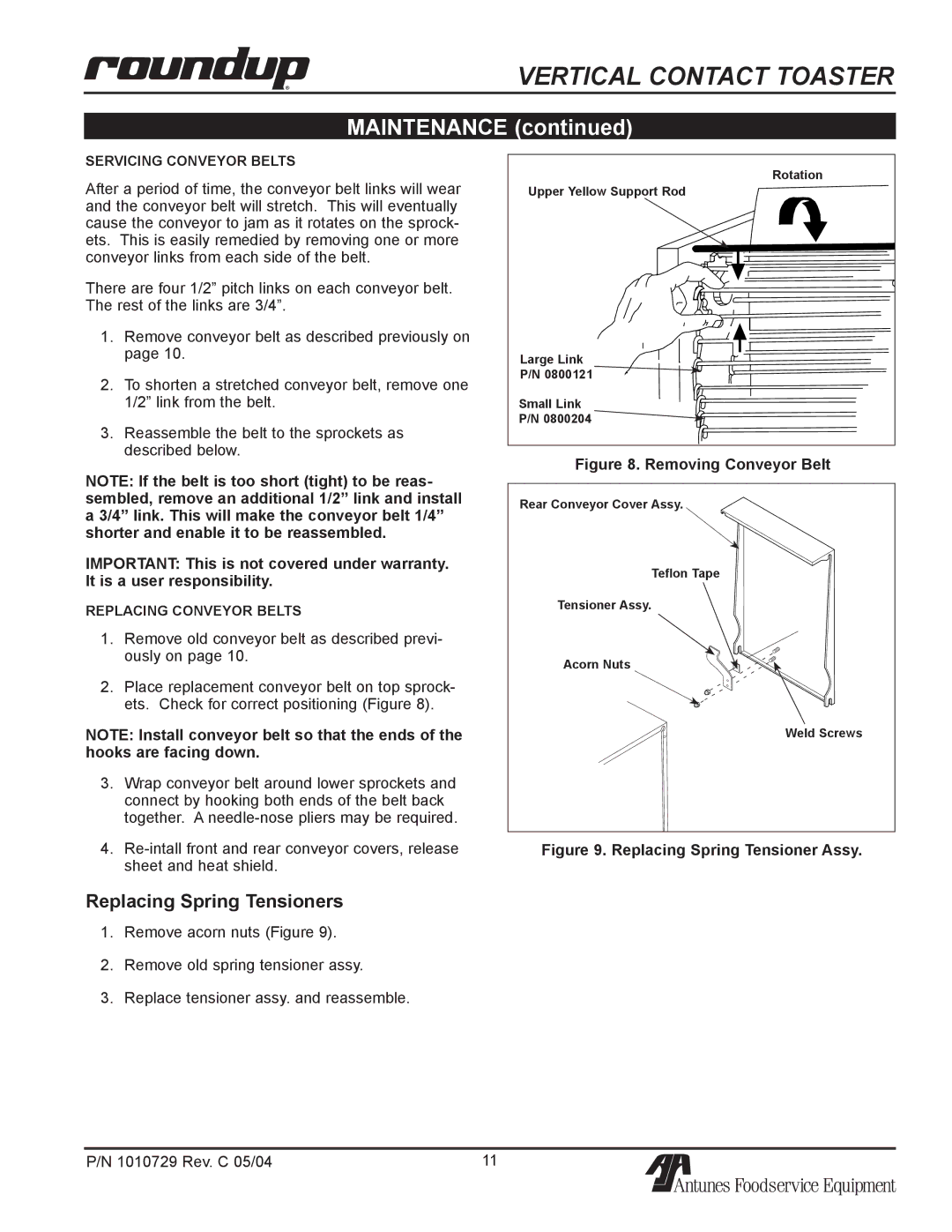

2.Place replacement conveyor belt on top sprock- ets. Check for correct positioning (Figure 8).

NOTE: Install conveyor belt so that the ends of the hooks are facing down.

3.Wrap conveyor belt around lower sprockets and connect by hooking both ends of the belt back together. A

4.

Rotation |

Upper Yellow Support Rod |

Large Link |

P/N 0800121 |

Small Link |

P/N 0800204 |

Figure 8. Removing Conveyor Belt

Rear Conveyor Cover Assy.

Teflon Tape

Tensioner Assy.

Acorn Nuts

Weld Screws

Figure 9. Replacing Spring Tensioner Assy.

Replacing Spring Tensioners

1.Remove acorn nuts (Figure 9).

2.Remove old spring tensioner assy.

3.Replace tensioner assy. and reassemble.

P/N 1010729 Rev. C 05/04 | 11 |