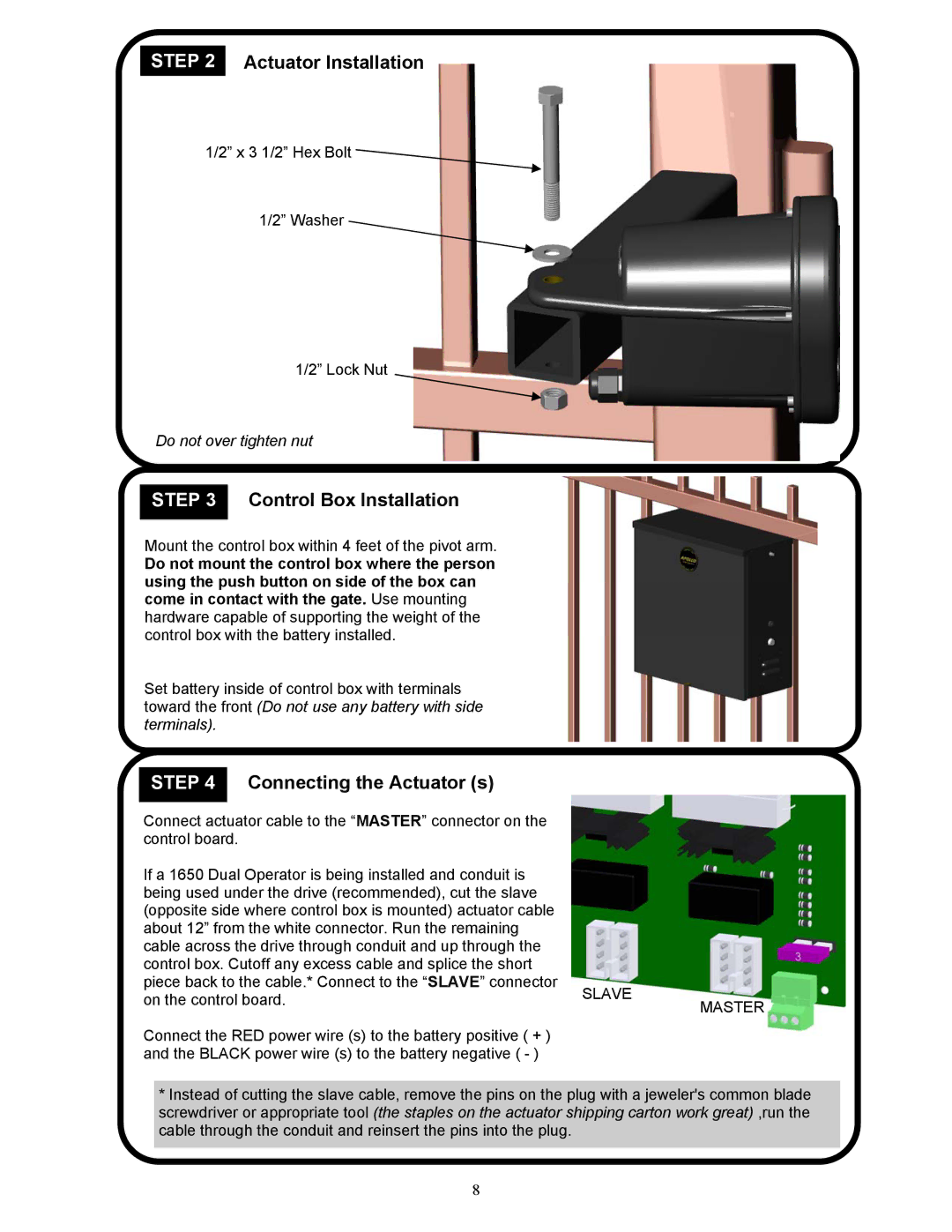

STEP 2 Actuator Installation

1/2” x 3 1/2” Hex Bolt ![]()

1/2” Washer

1/2” Lock Nut

Do not over tighten nut

STEP 3 Control Box Installation

Mount the control box within 4 feet of the pivot arm.

Do not mount the control box where the person using the push button on side of the box can come in contact with the gate. Use mounting hardware capable of supporting the weight of the control box with the battery installed.

Set battery inside of control box with terminals toward the front (Do not use any battery with side terminals).

STEP 4 Connecting the Actuator (s)

Connect actuator cable to the “MASTER” connector on the |

| |

control board. |

| |

If a 1650 Dual Operator is being installed and conduit is |

| |

being used under the drive (recommended), cut the slave |

| |

(opposite side where control box is mounted) actuator cable |

| |

about 12” from the white connector. Run the remaining |

| |

cable across the drive through conduit and up through the |

| |

control box. Cutoff any excess cable and splice the short |

| |

piece back to the cable.* Connect to the “SLAVE” connector | SLAVE | |

on the control board. | ||

MASTER | ||

| ||

Connect the RED power wire (s) to the battery positive ( + ) |

| |

and the BLACK power wire (s) to the battery negative ( - ) |

|

*Instead of cutting the slave cable, remove the pins on the plug with a jeweler's common blade screwdriver or appropriate tool (the staples on the actuator shipping carton work great) ,run the cable through the conduit and reinsert the pins into the plug.

8