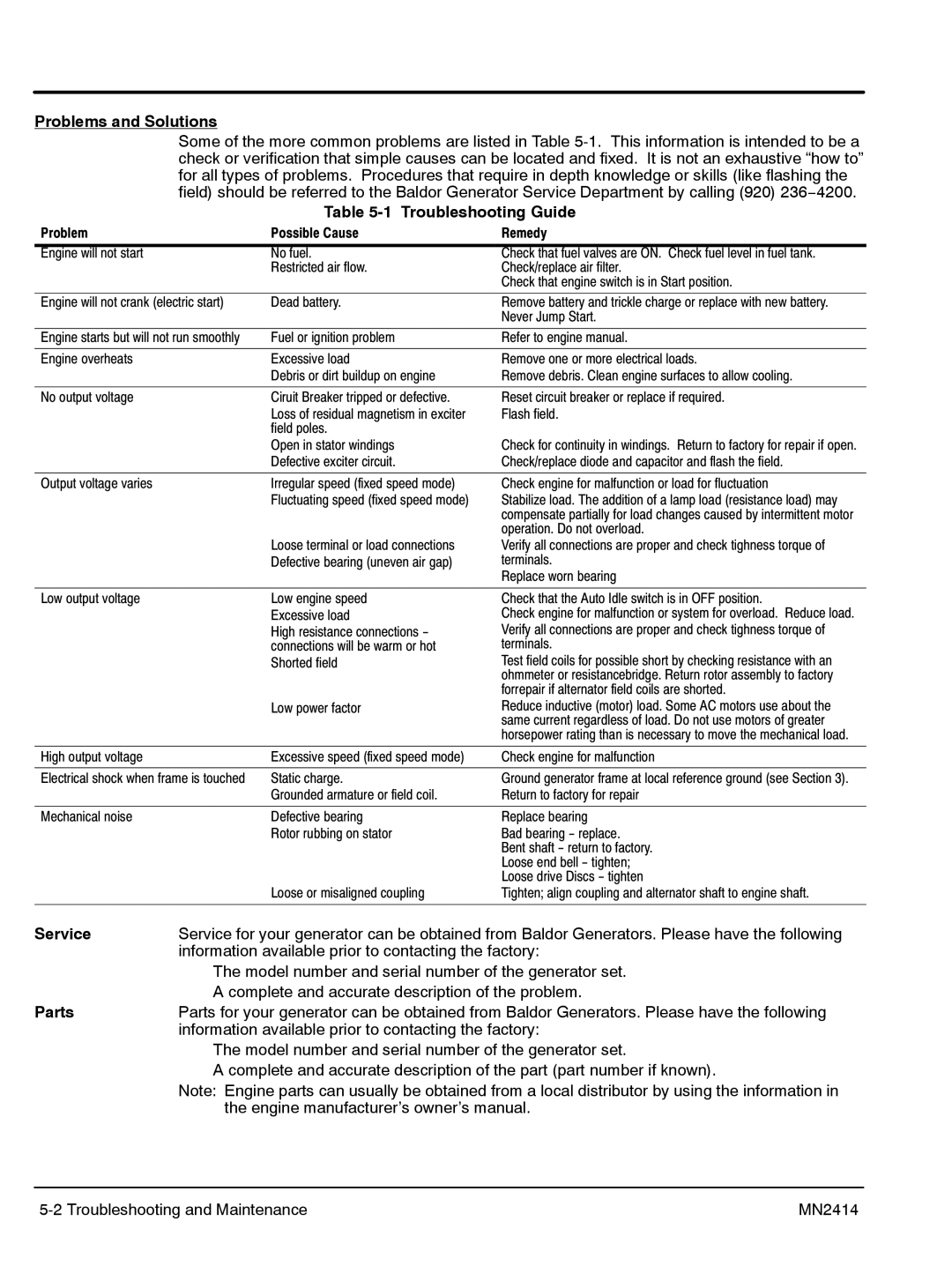

Problems and Solutions

Some of the more common problems are listed in Table

Table 5-1 Troubleshooting Guide

Problem | Possible Cause | Remedy |

|

|

|

Engine will not start | No fuel. | Check that fuel valves are ON. Check fuel level in fuel tank. |

| Restricted air flow. | Check/replace air filter. |

|

| Check that engine switch is in Start position. |

|

|

|

Engine will not crank (electric start) | Dead battery. | Remove battery and trickle charge or replace with new battery. |

|

| Never Jump Start. |

|

|

|

Engine starts but will not run smoothly | Fuel or ignition problem | Refer to engine manual. |

|

|

|

Engine overheats | Excessive load | Remove one or more electrical loads. |

| Debris or dirt buildup on engine | Remove debris. Clean engine surfaces to allow cooling. |

|

|

|

No output voltage | Ciruit Breaker tripped or defective. | Reset circuit breaker or replace if required. |

| Loss of residual magnetism in exciter | Flash field. |

| field poles. | Check for continuity in windings. Return to factory for repair if open. |

| Open in stator windings | |

| Defective exciter circuit. | Check/replace diode and capacitor and flash the field. |

|

|

|

Output voltage varies | Irregular speed (fixed speed mode) | Check engine for malfunction or load for fluctuation |

| Fluctuating speed (fixed speed mode) | Stabilize load. The addition of a lamp load (resistance load) may |

|

| compensate partially for load changes caused by intermittent motor |

|

| operation. Do not overload. |

Loose terminal or load connections Defective bearing (uneven air gap)

Verify all connections are proper and check tighness torque of terminals.

Replace worn bearing

Low output voltage | Low engine speed |

| Excessive load |

| High resistance connections − |

| connections will be warm or hot |

| Shorted field |

| Low power factor |

Check that the Auto Idle switch is in OFF position.

Check engine for malfunction or system for overload. Reduce load. Verify all connections are proper and check tighness torque of terminals.

Test field coils for possible short by checking resistance with an ohmmeter or resistancebridge. Return rotor assembly to factory forrepair if alternator field coils are shorted.

Reduce inductive (motor) load. Some AC motors use about the same current regardless of load. Do not use motors of greater horsepower rating than is necessary to move the mechanical load.

High output voltage | Excessive speed (fixed speed mode) | Check engine for malfunction |

Electrical shock when frame is touched | Static charge. | Ground generator frame at local reference ground (see Section 3). |

| Grounded armature or field coil. | Return to factory for repair |

|

|

|

Mechanical noise | Defective bearing | Replace bearing |

| Rotor rubbing on stator | Bad bearing − replace. |

|

| Bent shaft − return to factory. |

|

| Loose end bell − tighten; |

| Loose or misaligned coupling | Loose drive Discs − tighten |

| Tighten; align coupling and alternator shaft to engine shaft. | |

|

|

|

Service | Service for your generator can be obtained from Baldor Generators. Please have the following |

| information available prior to contacting the factory: |

| The model number and serial number of the generator set. |

| A complete and accurate description of the problem. |

Parts | Parts for your generator can be obtained from Baldor Generators. Please have the following |

| information available prior to contacting the factory: |

| The model number and serial number of the generator set. |

| A complete and accurate description of the part (part number if known). |

| Note: Engine parts can usually be obtained from a local distributor by using the information in |

| the engine manufacturer’s owner’s manual. |

MN2414 |