Frame Ground Connection

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power before you ensure that grounds are connected. Electrical shock can cause serious or fatal injury. NEC requires that the frame and exposed conductive surfaces (metal parts) be connected to an approved earth ground. Local codes may also require proper grounding of generator systems.

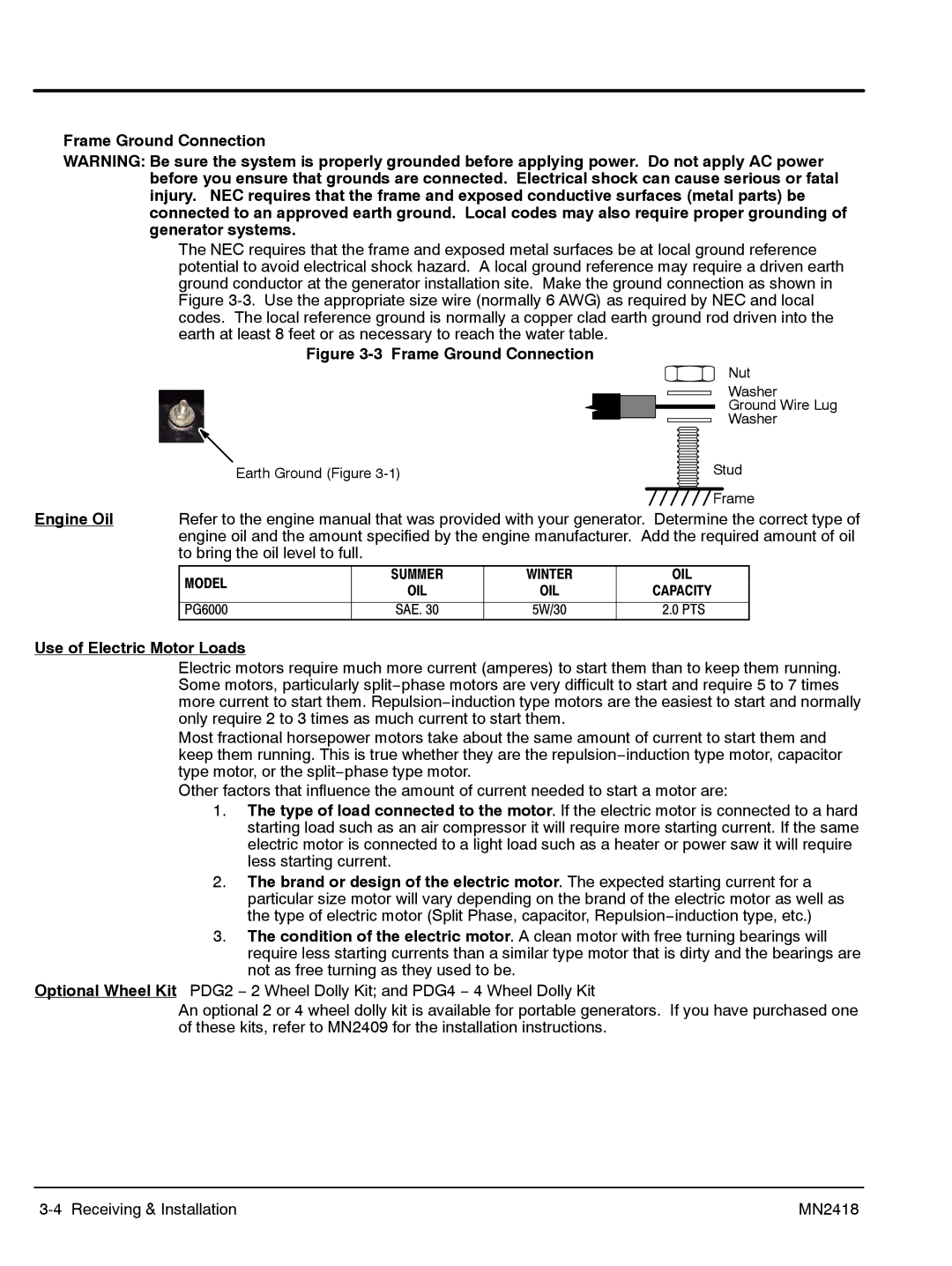

The NEC requires that the frame and exposed metal surfaces be at local ground reference potential to avoid electrical shock hazard. A local ground reference may require a driven earth ground conductor at the generator installation site. Make the ground connection as shown in Figure

Figure 3-3 Frame Ground Connection

|

|

|

| Nut |

|

|

|

| Washer |

|

|

|

| Ground Wire Lug |

|

|

|

| Washer |

|

| Earth Ground (Figure |

| Stud |

|

|

|

| Frame |

Engine Oil | Refer to the engine manual that was provided with your generator. Determine the correct type of | |||

| engine oil and the amount specified by the engine manufacturer. Add the required amount of oil | |||

| to bring the oil level to full. |

|

| |

| MODEL | SUMMER | WINTER | OIL |

| OIL | OIL | CAPACITY | |

|

| |||

| PG6000 | SAE. 30 | 5W/30 | 2.0 PTS |

Use of Electric Motor Loads

Electric motors require much more current (amperes) to start them than to keep them running. Some motors, particularly split−phase motors are very difficult to start and require 5 to 7 times more current to start them. Repulsion−induction type motors are the easiest to start and normally only require 2 to 3 times as much current to start them.

Most fractional horsepower motors take about the same amount of current to start them and keep them running. This is true whether they are the repulsion−induction type motor, capacitor type motor, or the split−phase type motor.

Other factors that influence the amount of current needed to start a motor are:

1.The type of load connected to the motor. If the electric motor is connected to a hard starting load such as an air compressor it will require more starting current. If the same electric motor is connected to a light load such as a heater or power saw it will require less starting current.

2.The brand or design of the electric motor. The expected starting current for a particular size motor will vary depending on the brand of the electric motor as well as the type of electric motor (Split Phase, capacitor, Repulsion−induction type, etc.)

3.The condition of the electric motor. A clean motor with free turning bearings will require less starting currents than a similar type motor that is dirty and the bearings are not as free turning as they used to be.

Optional Wheel Kit PDG2 − 2 Wheel Dolly Kit; and PDG4 − 4 Wheel Dolly Kit

An optional 2 or 4 wheel dolly kit is available for portable generators. If you have purchased one of these kits, refer to MN2409 for the installation instructions.

MN2418 |