OPEN LOOP (Well System Applications)

WATER CONNECTIONS

It is very important that an adequate supply of clean, noncorrosive water at the proper pressure be provided before the installation is made. Insufficient water, in the heating mode for example, will cause the low pressure switch to trip, shutting down the heat pump. In assessing the capacity of the water system, it is advisable that the complete water system be evaluated to prevent possible lack of water or water pressure at various household fixtures whenever the heat pump turns on. All plumbing to and from the unit is to be installed in accordance with local plumbing codes. The use of plastic pipe, where permissible, is recommended to prevent electrolytic corrosion of the water pipe. Because of the relatively cold temperatures encountered with well water, it is strongly recommended that the water lines connecting the unit be insulated to prevent water droplets form condensing on the pipe surface.

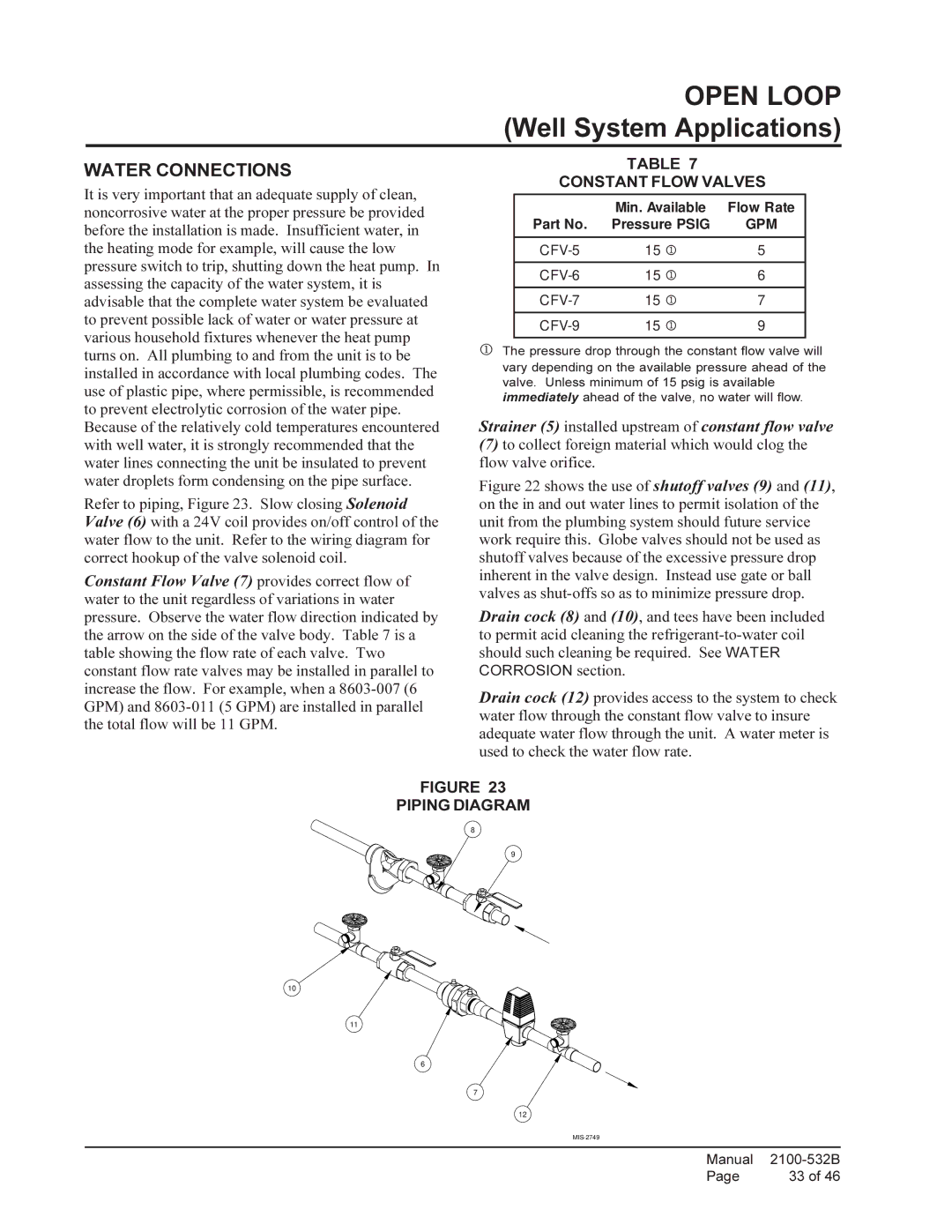

Refer to piping, Figure 23. Slow closing Solenoid Valve (6) with a 24V coil provides on/off control of the water flow to the unit. Refer to the wiring diagram for correct hookup of the valve solenoid coil.

Constant Flow Valve (7) provides correct flow of water to the unit regardless of variations in water pressure. Observe the water flow direction indicated by the arrow on the side of the valve body. Table 7 is a table showing the flow rate of each valve. Two constant flow rate valves may be installed in parallel to increase the flow. For example, when a

TABLE 7

CONSTANT FLOW VALVES

| Min. Available | Flow Rate |

Part No. | Pressure PSIG | GPM |

|

|

|

| 15 1 | 5 |

|

|

|

| 15 1 | 6 |

|

|

|

| 15 1 | 7 |

|

|

|

| 15 1 | 9 |

|

|

|

1The pressure drop through the constant flow valve will vary depending on the available pressure ahead of the valve. Unless minimum of 15 psig is available immediately ahead of the valve, no water will flow.

Strainer (5) installed upstream of constant flow valve

(7)to collect foreign material which would clog the flow valve orifice.

Figure 22 shows the use of shutoff valves (9) and (11), on the in and out water lines to permit isolation of the unit from the plumbing system should future service work require this. Globe valves should not be used as shutoff valves because of the excessive pressure drop inherent in the valve design. Instead use gate or ball valves as shut-offs so as to minimize pressure drop.

Drain cock (8) and (10), and tees have been included to permit acid cleaning the refrigerant-to-water coil should such cleaning be required. See WATER CORROSION section.

Drain cock (12) provides access to the system to check water flow through the constant flow valve to insure adequate water flow through the unit. A water meter is used to check the water flow rate.

FIGURE 23

PIPING DIAGRAM

8

9

10

11

6

7

12

Manual | |

Page | 33 of 46 |