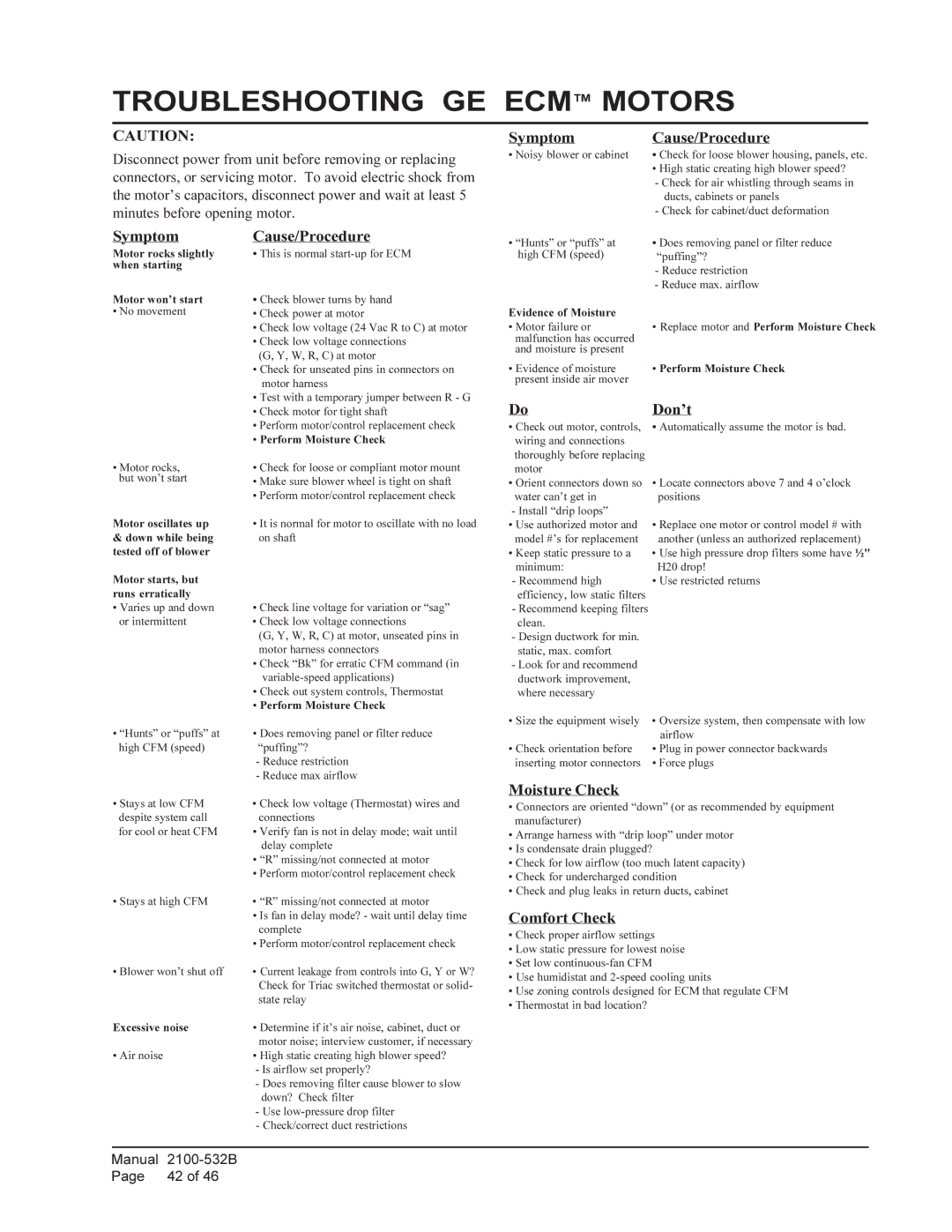

TROUBLESHOOTING GE ECM™ MOTORS

CAUTION:

Disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor.

Symptom Cause/Procedure

Symptom Cause/Procedure

•Noisy blower or cabinet • Check for loose blower housing, panels, etc.

•High static creating high blower speed?

-Check for air whistling through seams in ducts, cabinets or panels

-Check for cabinet/duct deformation

•“Hunts” or “puffs” at • Does removing panel or filter reduce

Motor rocks slightly when starting

Motor won’t start

• No movement

• This is normal |

• Check blower turns by hand |

• Check power at motor |

• Check low voltage (24 Vac R to C) at motor |

• Check low voltage connections |

(G, Y, W, R, C) at motor |

• Check for unseated pins in connectors on |

motor harness |

• Test with a temporary jumper between R - G |

• Check motor for tight shaft |

high CFM (speed) | “puffing”? |

| - Reduce restriction |

| - Reduce max. airflow |

Evidence of Moisture |

|

• Motor failure or | • Replace motor and Perform Moisture Check |

malfunction has occurred |

|

and moisture is present |

|

• Evidence of moisture | • Perform Moisture Check |

present inside air mover |

|

Do | Don’t |

• Perform motor/control replacement check |

• Perform Moisture Check |

• Check out motor, controls, |

wiring and connections |

thoroughly before replacing |

• Automatically assume the motor is bad. |

• Motor rocks, | • Check for loose or compliant motor mount |

but won’t start | • Make sure blower wheel is tight on shaft |

| |

| • Perform motor/control replacement check |

Motor oscillates up | • It is normal for motor to oscillate with no load |

& down while being | on shaft |

tested off of blower |

|

Motor starts, but |

|

runs erratically |

|

• Varies up and down | • Check line voltage for variation or “sag” |

or intermittent | • Check low voltage connections |

| (G, Y, W, R, C) at motor, unseated pins in |

| motor harness connectors |

| • Check “Bk” for erratic CFM command (in |

| |

| • Check out system controls, Thermostat |

| • Perform Moisture Check |

• “Hunts” or “puffs” at | • Does removing panel or filter reduce |

high CFM (speed) | “puffing”? |

| - Reduce restriction |

| - Reduce max airflow |

motor |

• Orient connectors down so |

water can’t get in |

- Install “drip loops” |

• Use authorized motor and |

model #’s for replacement |

• Keep static pressure to a |

minimum: |

- Recommend high |

efficiency, low static filters |

- Recommend keeping filters |

clean. |

- Design ductwork for min. |

static, max. comfort |

- Look for and recommend |

ductwork improvement, |

where necessary |

• Size the equipment wisely |

• Check orientation before |

inserting motor connectors |

• Locate connectors above 7 and 4 o’clock |

positions |

• Replace one motor or control model # with |

another (unless an authorized replacement) |

• Use high pressure drop filters some have ½" |

H20 drop! |

• Use restricted returns |

•Oversize system, then compensate with low airflow

•Plug in power connector backwards

•Force plugs

• Stays at low CFM | • Check low voltage (Thermostat) wires and |

despite system call | connections |

for cool or heat CFM | • Verify fan is not in delay mode; wait until |

| delay complete |

| • “R” missing/not connected at motor |

| • Perform motor/control replacement check |

• Stays at high CFM | • “R” missing/not connected at motor |

| • Is fan in delay mode? - wait until delay time |

| complete |

| • Perform motor/control replacement check |

• Blower won’t shut off | • Current leakage from controls into G, Y or W? |

| Check for Triac switched thermostat or solid- |

| state relay |

Excessive noise | • Determine if it’s air noise, cabinet, duct or |

| motor noise; interview customer, if necessary |

• Air noise | • High static creating high blower speed? |

| - Is airflow set properly? |

| - Does removing filter cause blower to slow |

| down? Check filter |

| - Use |

| - Check/correct duct restrictions |

Moisture Check

•Connectors are oriented “down” (or as recommended by equipment manufacturer)

•Arrange harness with “drip loop” under motor

•Is condensate drain plugged?

•Check for low airflow (too much latent capacity)

•Check for undercharged condition

•Check and plug leaks in return ducts, cabinet

Comfort Check

•Check proper airflow settings

•Low static pressure for lowest noise

•Set low

•Use humidistat and

•Use zoning controls designed for ECM that regulate CFM

•Thermostat in bad location?

Manual | |

Page | 42 of 46 |