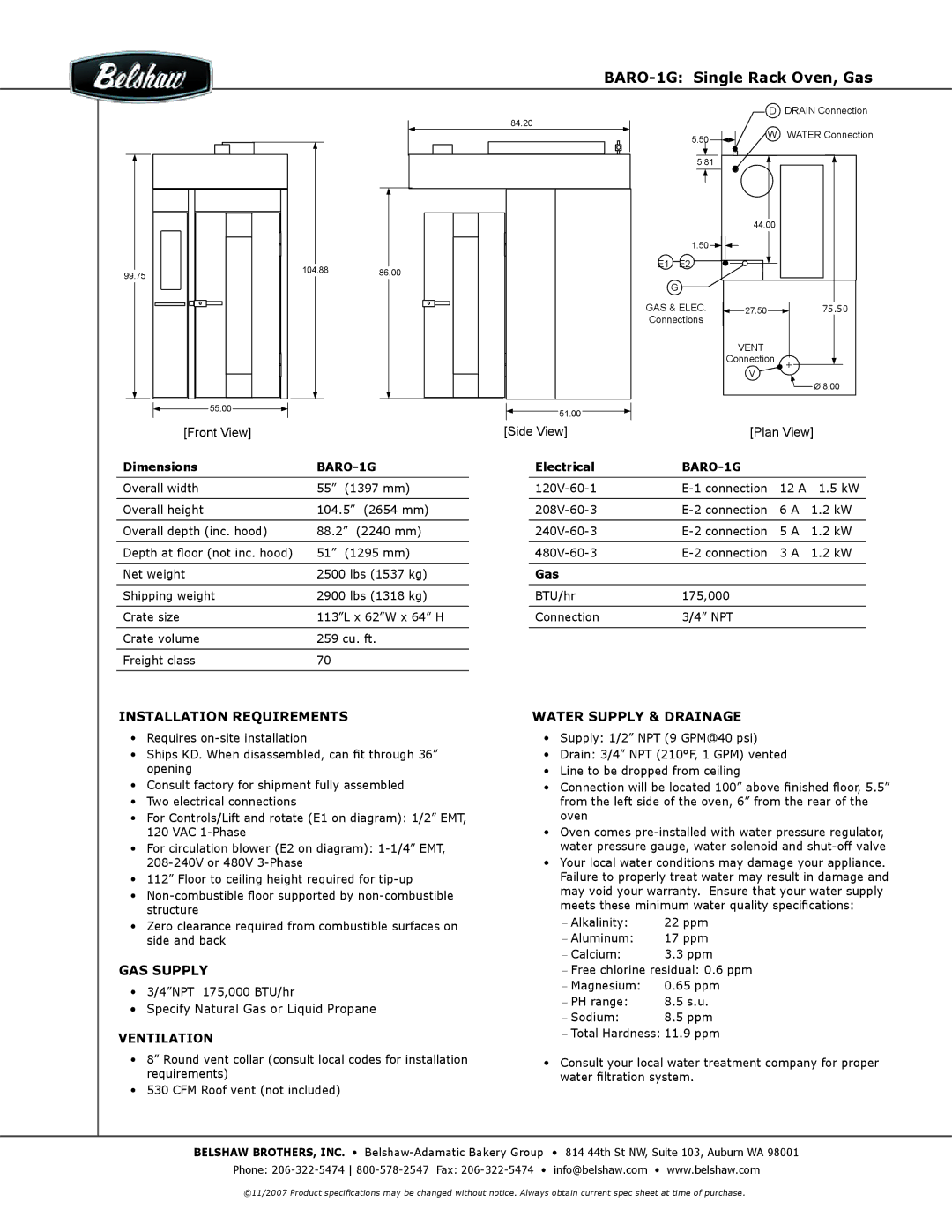

BARO-1G specifications

The Belshaw Brothers BARO-1G is a state-of-the-art donut fryer that has garnered attention for its efficiency and reliability in the commercial kitchen environment. Designed for high-volume production, the BARO-1G provides bakers and foodservice operators with an excellent solution for crafting delicious, perfectly fried donuts.One of the key features of the BARO-1G is its advanced temperature control technology. The fryer is equipped with an automatic temperature control system that ensures consistent frying temperatures, crucial for achieving the perfect texture and flavor in donuts. This technology minimizes the risk of undercooking or overcooking, which can compromise product quality.

Another standout characteristic of the BARO-1G is its energy-efficient design. The fryer is built to minimize energy consumption while maintaining optimal performance. This is particularly important for businesses looking to manage operational costs without sacrificing product quality. With energy-efficient heating elements, the BARO-1G allows operators to maximize their output while reducing energy bills.

The BARO-1G also boasts a spacious frying area, allowing users to fry a large batch of donuts at once. This feature enhances productivity and helps in meeting high demand during peak hours. The spacious design is complemented by a continuous oil filtration system, which extends the life of the cooking oil and ensures that every batch of donuts is fried in clean oil, enhancing flavor and quality.

Durability is another hallmark of the BARO-1G. Constructed with heavy-duty materials, this fryer is designed to withstand the rigors of a busy commercial kitchen. Its robust build ensures longevity, making it a wise investment for any foodservice establishment.

Easy-to-use controls are an additional feature that sets the BARO-1G apart from its competitors. The intuitive control panel allows operators to adjust the frying time and temperature with precision and ease. This user-friendly interface means that even new staff can quickly learn to operate the fryer effectively.

In summary, the Belshaw Brothers BARO-1G is an exceptional choice for any bakery or foodservice business looking to enhance their donut production. With its advanced temperature control, energy efficiency, spacious frying area, durability, and user-friendly design, it embodies the quality and functionality that modern kitchens demand. Investing in the BARO-1G means investing in excellent product quality and operational efficiency.