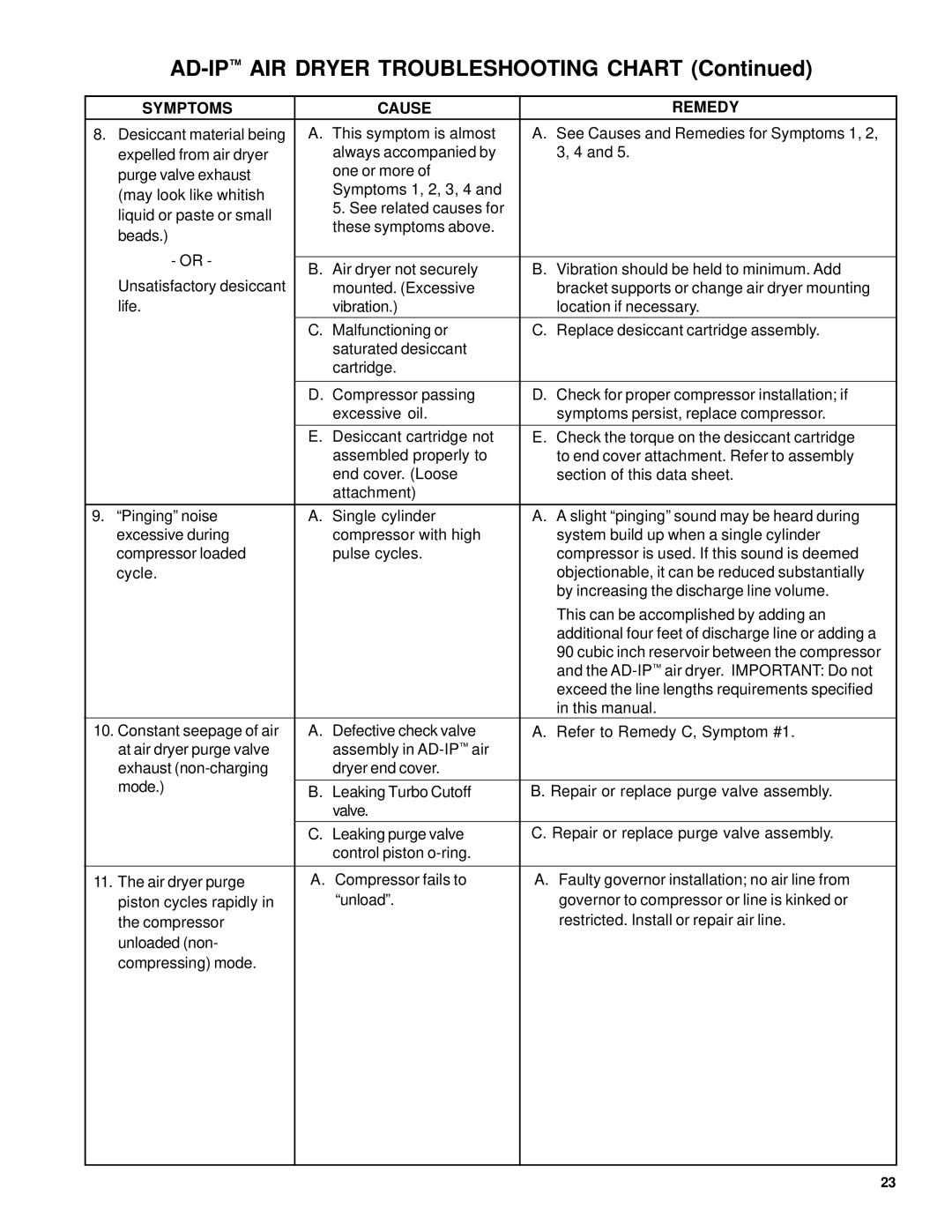

AD-IP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

| SYMPTOMS | CAUSE | REMEDY |

8. | Desiccant material being | A. This symptom is almost | A. See Causes and Remedies for Symptoms 1, 2, |

| expelled from air dryer | always accompanied by | 3, 4 and 5. |

| purge valve exhaust | one or more of |

|

| (may look like whitish | Symptoms 1, 2, 3, 4 and |

|

| 5. See related causes for |

| |

| liquid or paste or small |

| |

| these symptoms above. |

| |

| beads.) |

| |

|

|

| |

| - OR - |

|

|

| B. Air dryer not securely | B. Vibration should be held to minimum. Add | |

| Unsatisfactory desiccant | ||

| mounted. (Excessive | bracket supports or change air dryer mounting | |

| life. | vibration.) | location if necessary. |

|

|

|

|

|

| C. Malfunctioning or | C. Replace desiccant cartridge assembly. |

|

| saturated desiccant |

|

|

| cartridge. |

|

|

|

|

|

|

| D. Compressor passing | D. Check for proper compressor installation; if |

|

| excessive oil. | symptoms persist, replace compressor. |

|

|

|

|

|

| E. Desiccant cartridge not | E. Check the torque on the desiccant cartridge |

|

| assembled properly to | to end cover attachment. Refer to assembly |

|

| end cover. (Loose | section of this data sheet. |

|

| attachment) |

|

|

|

|

|

9. | “Pinging” noise | A. Single cylinder | A. A slight “pinging” sound may be heard during |

| excessive during | compressor with high | system build up when a single cylinder |

| compressor loaded | pulse cycles. | compressor is used. If this sound is deemed |

| cycle. |

| objectionable, it can be reduced substantially |

|

|

| by increasing the discharge line volume. |

|

|

| This can be accomplished by adding an |

|

|

| additional four feet of discharge line or adding a |

|

|

| 90 cubic inch reservoir between the compressor |

|

|

| and the |

|

|

| exceed the line lengths requirements specified |

|

|

| in this manual. |

10. Constant seepage of air | A. Defective check valve | A. Refer to Remedy C, Symptom #1. | |

| at air dryer purge valve | assembly in |

|

| exhaust | dryer end cover. |

|

| mode.) |

|

|

| B. Leaking Turbo Cutoff | B. Repair or replace purge valve assembly. | |

|

| valve. |

|

|

|

|

|

|

| C. Leaking purge valve | C. Repair or replace purge valve assembly. |

|

| control piston |

|

|

|

| |

11. The air dryer purge | A. Compressor fails to | A. Faulty governor installation; no air line from | |

| piston cycles rapidly in | “unload”. | governor to compressor or line is kinked or |

| the compressor |

| restricted. Install or repair air line. |

| unloaded (non- |

|

|

| compressing) mode. |

|

|

|

|

|

|

23