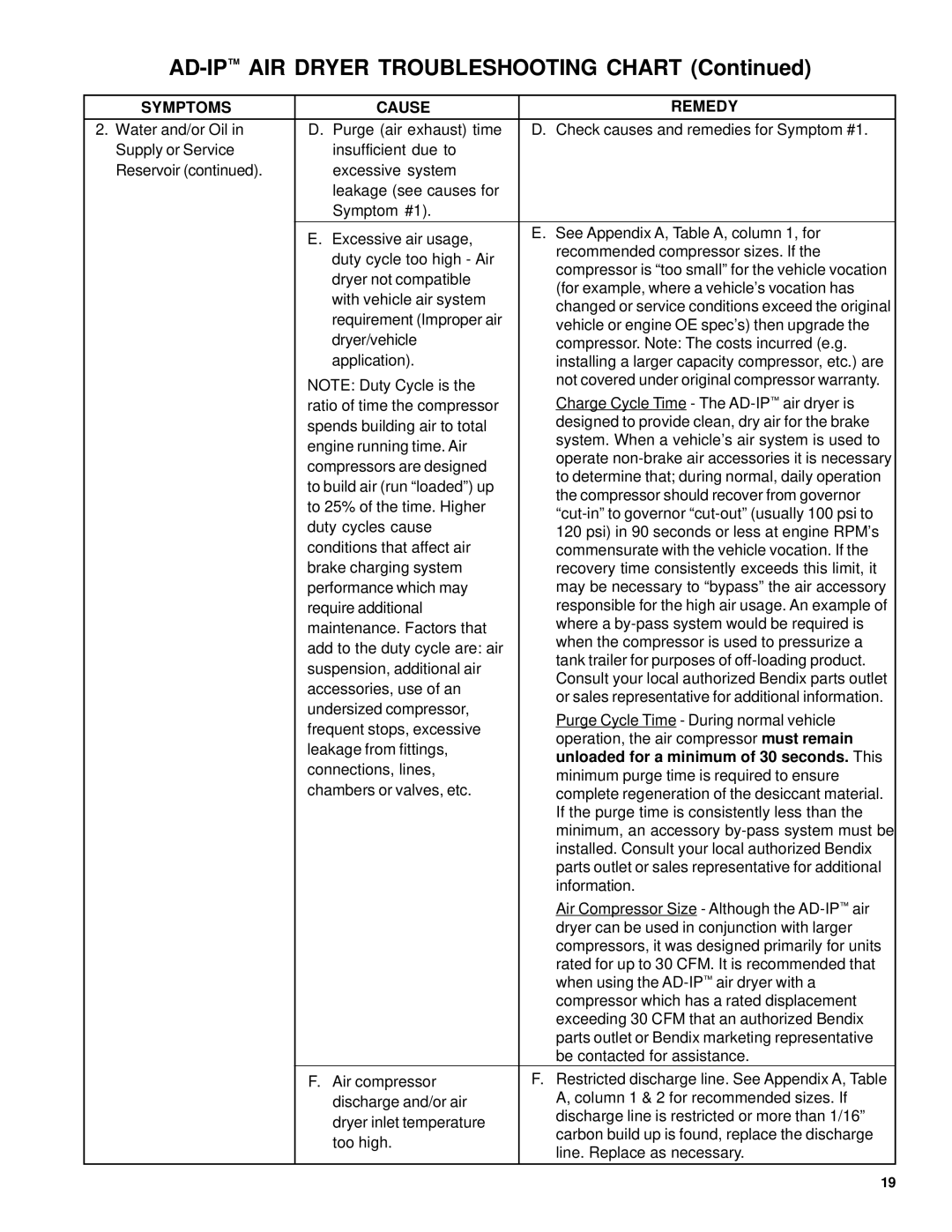

AD-IP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS |

| CAUSE | REMEDY | |

|

|

|

| |

2. Water and/or Oil in | D. | Purge (air exhaust) time | D. Check causes and remedies for Symptom #1. | |

Supply or Service |

| insufficient due to |

| |

Reservoir (continued). |

| excessive system |

| |

|

|

| leakage (see causes for |

|

|

|

| Symptom #1). |

|

|

|

|

|

|

|

| E. Excessive air usage, | E. See Appendix A, Table A, column 1, for | |

|

| recommended compressor sizes. If the | ||

|

|

| duty cycle too high - Air | |

|

|

| compressor is “too small” for the vehicle vocation | |

|

|

| dryer not compatible | |

|

|

| (for example, where a vehicle’s vocation has | |

|

|

| with vehicle air system | |

|

|

| changed or service conditions exceed the original | |

|

|

| requirement (Improper air | |

|

|

| vehicle or engine OE spec’s) then upgrade the | |

|

|

| dryer/vehicle | |

|

|

| compressor. Note: The costs incurred (e.g. | |

|

|

| application). | installing a larger capacity compressor, etc.) are |

|

| NOTE: Duty Cycle is the | not covered under original compressor warranty. | |

|

| Charge Cycle Time - The | ||

|

| ratio of time the compressor | ||

|

| spends building air to total | designed to provide clean, dry air for the brake | |

|

| system. When a vehicle’s air system is used to | ||

|

| engine running time. Air | ||

|

| operate | ||

|

| compressors are designed | ||

|

| to determine that; during normal, daily operation | ||

|

| to build air (run “loaded”) up | ||

|

| the compressor should recover from governor | ||

|

| to 25% of the time. Higher | ||

|

| |||

|

| duty cycles cause | ||

|

| 120 psi) in 90 seconds or less at engine RPM’s | ||

|

| conditions that affect air | ||

|

| commensurate with the vehicle vocation. If the | ||

|

| brake charging system | recovery time consistently exceeds this limit, it | |

|

| performance which may | may be necessary to “bypass” the air accessory | |

|

| require additional | responsible for the high air usage. An example of | |

|

| maintenance. Factors that | where a | |

|

| when the compressor is used to pressurize a | ||

|

| add to the duty cycle are: air | ||

|

| tank trailer for purposes of | ||

|

| suspension, additional air | ||

|

| Consult your local authorized Bendix parts outlet | ||

|

| accessories, use of an | ||

|

| or sales representative for additional information. | ||

|

| undersized compressor, | ||

|

| Purge Cycle Time - During normal vehicle | ||

|

| frequent stops, excessive | ||

|

| operation, the air compressor must remain | ||

|

| leakage from fittings, | ||

|

| unloaded for a minimum of 30 seconds. This | ||

|

| connections, lines, | ||

|

| minimum purge time is required to ensure | ||

|

| chambers or valves, etc. | ||

|

| complete regeneration of the desiccant material. | ||

|

|

|

| If the purge time is consistently less than the |

|

|

|

| minimum, an accessory |

|

|

|

| installed. Consult your local authorized Bendix |

|

|

|

| parts outlet or sales representative for additional |

|

|

|

| information. |

|

|

|

| Air Compressor Size - Although the |

|

|

|

| dryer can be used in conjunction with larger |

|

|

|

| compressors, it was designed primarily for units |

|

|

|

| rated for up to 30 CFM. It is recommended that |

|

|

|

| when using the |

|

|

|

| compressor which has a rated displacement |

|

|

|

| exceeding 30 CFM that an authorized Bendix |

|

|

|

| parts outlet or Bendix marketing representative |

|

|

|

| be contacted for assistance. |

|

| F. | Air compressor | F. Restricted discharge line. See Appendix A, Table |

|

|

| discharge and/or air | A, column 1 & 2 for recommended sizes. If |

|

|

| dryer inlet temperature | discharge line is restricted or more than 1/16” |

|

|

| carbon build up is found, replace the discharge | |

|

|

| too high. | |

|

|

| line. Replace as necessary. | |

|

|

|

| |

|

|

|

|

|

19