PURGE EXHAUST LINE

1.If it is necessary to direct AD-IP™air dryer discharge contaminants away from vehicle components it will be necessary to purchase a special exhaust cover for the AD-IP™air dryer (Pc. No. 112609) and install on the unit. A 1” (25.4 mm) I.D. hose can be clamped on the special AD-IP™air dryer exhaust cover.

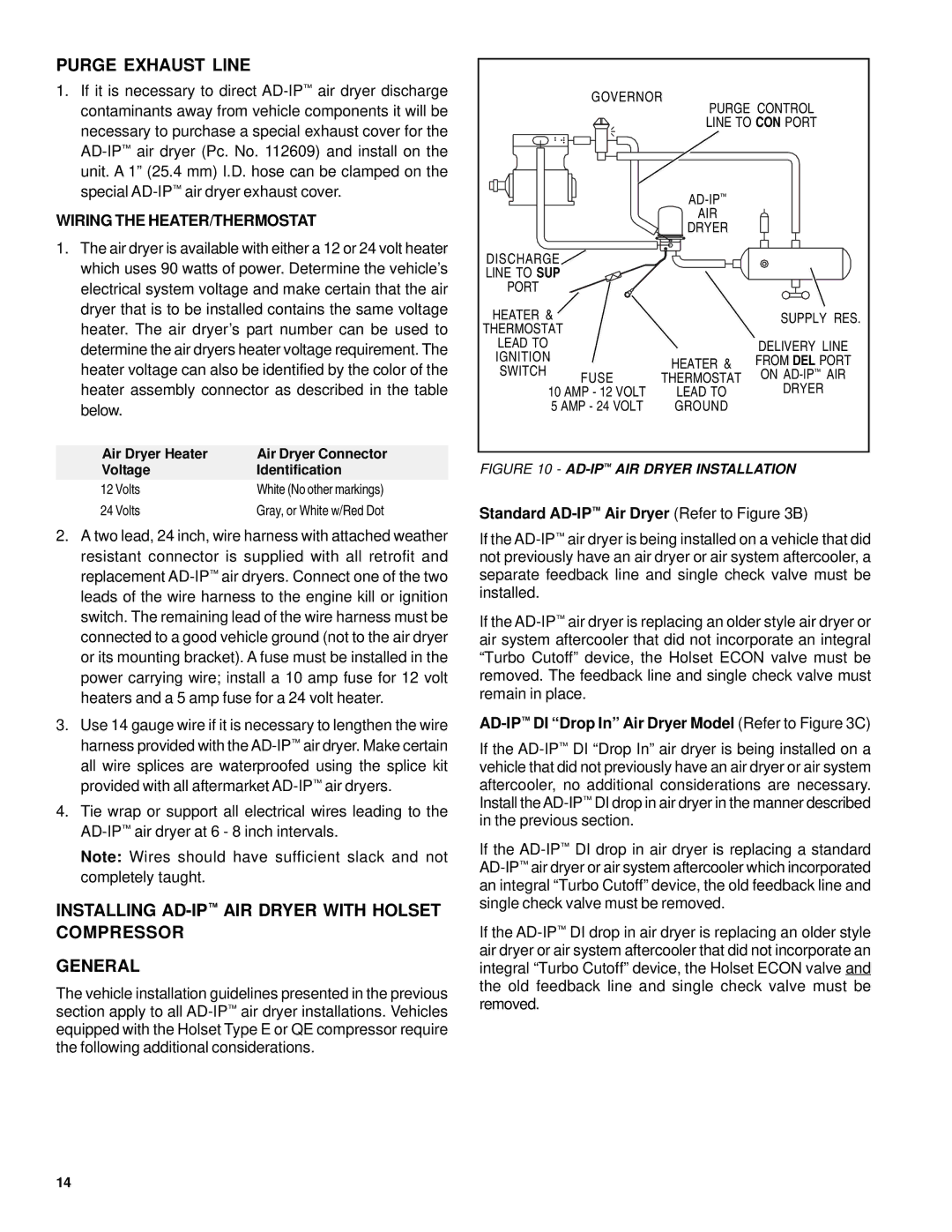

WIRING THE HEATER/THERMOSTAT

1.The air dryer is available with either a 12 or 24 volt heater which uses 90 watts of power. Determine the vehicle’s electrical system voltage and make certain that the air dryer that is to be installed contains the same voltage heater. The air dryer’s part number can be used to determine the air dryers heater voltage requirement. The heater voltage can also be identified by the color of the heater assembly connector as described in the table below.

Air Dryer Heater | Air Dryer Connector |

Voltage | Identification |

12 Volts | White (No other markings) |

24 Volts | Gray, or White w/Red Dot |

2.A two lead, 24 inch, wire harness with attached weather resistant connector is supplied with all retrofit and replacement AD-IP™air dryers. Connect one of the two leads of the wire harness to the engine kill or ignition switch. The remaining lead of the wire harness must be connected to a good vehicle ground (not to the air dryer or its mounting bracket). A fuse must be installed in the power carrying wire; install a 10 amp fuse for 12 volt heaters and a 5 amp fuse for a 24 volt heater.

3.Use 14 gauge wire if it is necessary to lengthen the wire harness provided with the AD-IP™air dryer. Make certain all wire splices are waterproofed using the splice kit provided with all aftermarket AD-IP™air dryers.

4.Tie wrap or support all electrical wires leading to the AD-IP™air dryer at 6 - 8 inch intervals.

Note: Wires should have sufficient slack and not completely taught.

INSTALLING AD-IP™AIR DRYER WITH HOLSET COMPRESSOR

GENERAL

The vehicle installation guidelines presented in the previous section apply to all AD-IP™air dryer installations. Vehicles equipped with the Holset Type E or QE compressor require the following additional considerations.

| GOVERNOR | |

| | PURGE CONTROL |

| | LINE TO CON PORT |

| | AD-IP™ | |

| | AIR | |

| | DRYER | |

DISCHARGE | | | |

LINE TO SUP | | | |

PORT | | | |

HEATER & | | | SUPPLY RES. |

THERMOSTAT | | | |

LEAD TO | | | DELIVERY LINE |

IGNITION | | HEATER & | FROM DEL PORT |

SWITCH | FUSE | THERMOSTAT | ON AD-IP™AIR |

10 AMP - 12 VOLT | LEAD TO | DRYER |

5 AMP - 24 VOLT | GROUND | |

FIGURE 10 - AD-IP™AIR DRYER INSTALLATION

Standard AD-IP™Air Dryer (Refer to Figure 3B)

If the AD-IP™air dryer is being installed on a vehicle that did not previously have an air dryer or air system aftercooler, a separate feedback line and single check valve must be installed.

If the AD-IP™air dryer is replacing an older style air dryer or air system aftercooler that did not incorporate an integral “Turbo Cutoff” device, the Holset ECON valve must be removed. The feedback line and single check valve must remain in place.

AD-IP™DI “Drop In” Air Dryer Model (Refer to Figure 3C)

If the AD-IP™DI “Drop In” air dryer is being installed on a vehicle that did not previously have an air dryer or air system aftercooler, no additional considerations are necessary. Install theAD-IP™DI drop in air dryer in the manner described in the previous section.

If the AD-IP™DI drop in air dryer is replacing a standard AD-IP™air dryer or air system aftercooler which incorporated an integral “Turbo Cutoff” device, the old feedback line and single check valve must be removed.

If the AD-IP™DI drop in air dryer is replacing an older style air dryer or air system aftercooler that did not incorporate an integral “Turbo Cutoff” device, the Holset ECON valve and the old feedback line and single check valve must be removed.