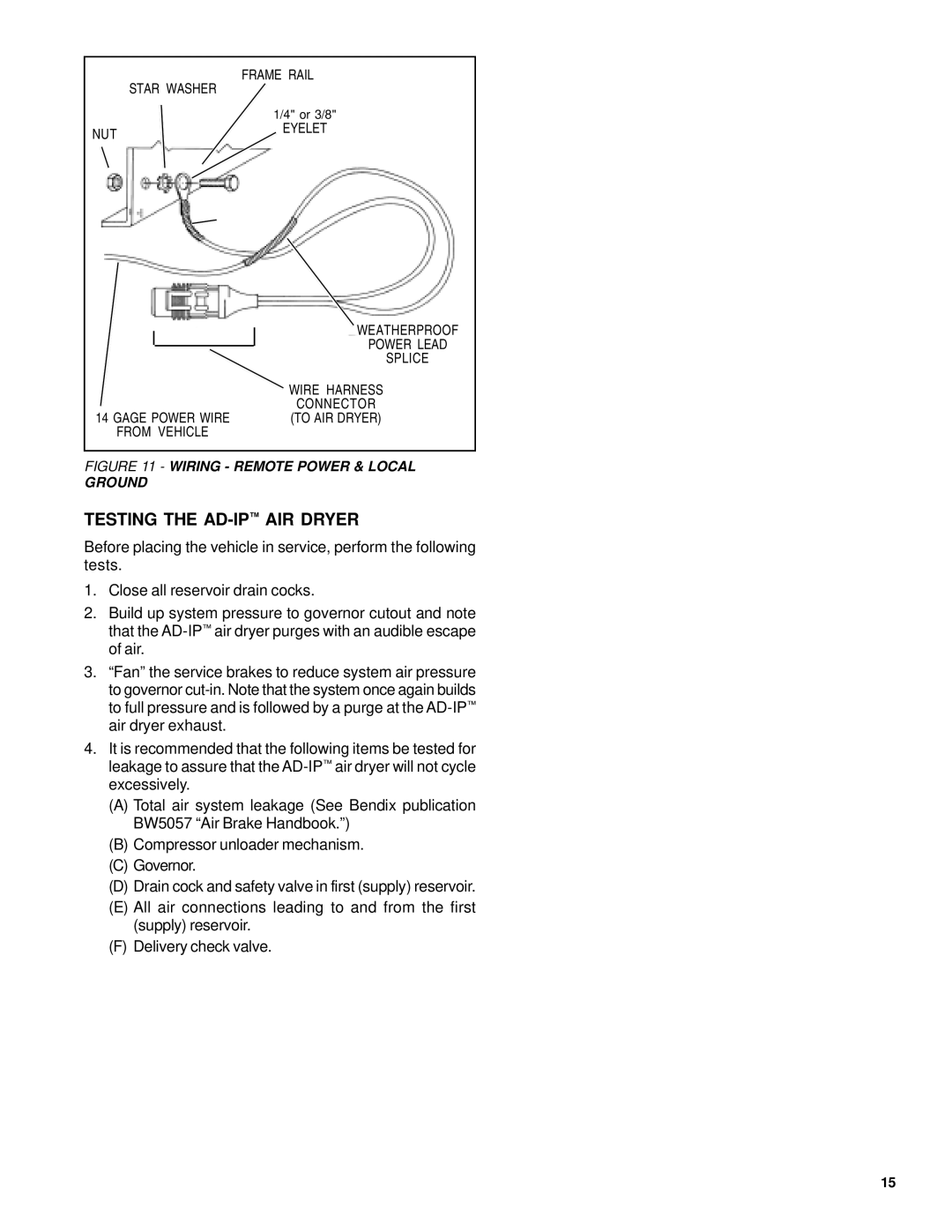

FRAME RAIL

STAR WASHER

1/4" or 3/8"

NUTEYELET

![]() GROUND

GROUND

LEAD

WEATHERPROOF

POWER LEAD

SPLICE

WIRE HARNESS

CONNECTOR

14 GAGE POWER WIRE(TO AIR DRYER) FROM VEHICLE

FIGURE 11 - WIRING - REMOTE POWER & LOCAL

GROUND

TESTING THE AD-IP™ AIR DRYER

Before placing the vehicle in service, perform the following tests.

1.Close all reservoir drain cocks.

2.Build up system pressure to governor cutout and note that the

3.“Fan” the service brakes to reduce system air pressure to governor

4.It is recommended that the following items be tested for leakage to assure that the

(A)Total air system leakage (See Bendix publication BW5057 “Air Brake Handbook.”)

(B)Compressor unloader mechanism.

(C)Governor.

(D)Drain cock and safety valve in first (supply) reservoir.

(E)All air connections leading to and from the first (supply) reservoir.

(F)Delivery check valve.

15