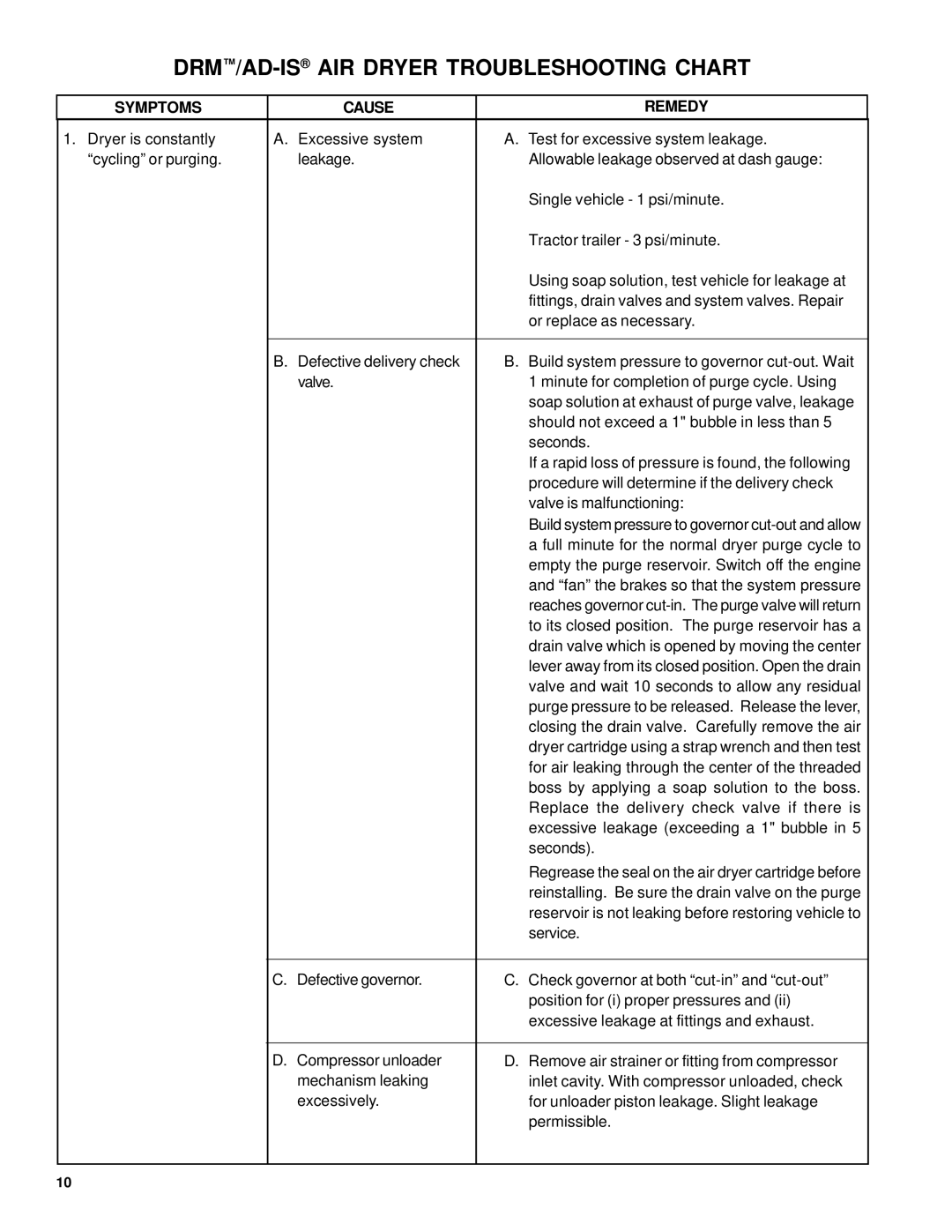

DRM™/AD-IS® AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS | CAUSE | REMEDY |

1. Dryer is constantly | A. Excessive system | A. Test for excessive system leakage. |

“cycling” or purging. | leakage. | Allowable leakage observed at dash gauge: |

|

| Single vehicle - 1 psi/minute. |

|

| Tractor trailer - 3 psi/minute. |

|

| Using soap solution, test vehicle for leakage at |

|

| fittings, drain valves and system valves. Repair |

|

| or replace as necessary. |

|

|

|

| B. Defective delivery check | B. Build system pressure to governor |

| valve. | 1 minute for completion of purge cycle. Using |

|

| soap solution at exhaust of purge valve, leakage |

|

| should not exceed a 1" bubble in less than 5 |

|

| seconds. |

|

| If a rapid loss of pressure is found, the following |

|

| procedure will determine if the delivery check |

|

| valve is malfunctioning: |

|

| Build system pressure to governor |

|

| a full minute for the normal dryer purge cycle to |

|

| empty the purge reservoir. Switch off the engine |

|

| and “fan” the brakes so that the system pressure |

|

| reaches governor |

|

| to its closed position. The purge reservoir has a |

|

| drain valve which is opened by moving the center |

|

| lever away from its closed position. Open the drain |

|

| valve and wait 10 seconds to allow any residual |

|

| purge pressure to be released. Release the lever, |

|

| closing the drain valve. Carefully remove the air |

|

| dryer cartridge using a strap wrench and then test |

|

| for air leaking through the center of the threaded |

|

| boss by applying a soap solution to the boss. |

|

| Replace the delivery check valve if there is |

|

| excessive leakage (exceeding a 1" bubble in 5 |

|

| seconds). |

|

| Regrease the seal on the air dryer cartridge before |

|

| reinstalling. Be sure the drain valve on the purge |

|

| reservoir is not leaking before restoring vehicle to |

|

| service. |

|

|

|

| C. Defective governor. | C. Check governor at both |

|

| position for (i) proper pressures and (ii) |

|

| excessive leakage at fittings and exhaust. |

|

|

|

| D. Compressor unloader | D. Remove air strainer or fitting from compressor |

| mechanism leaking | inlet cavity. With compressor unloaded, check |

| excessively. | for unloader piston leakage. Slight leakage |

|

| permissible. |

|

|

|

10