DELIVERY

CHECK

VALVE

GOVERNOR (CLOSED)

UNLOADER

PORT

PURGE

INLET CONTROL

PORT CHANNEL (IN) ![]()

TURBO

CUTOFF EXHAUST

VALVE PURGE (CLOSED) VALVE

(OPEN)

ENGINE

TURBO

![]() COMPRESSOR

COMPRESSOR

GOVERNOR SIGNALS AIR

COMPRESSOR TO SUSPEND

COMPRESSED AIR SUPPLY

TO

SAFETY

VALVE

DESICCANT

BED

OIL

SEPARATOR

PURGE

ORIFICE

PURGE

RESERVOIR

PRESSURE PROTECTION

VALVES

A

B C D

PRIMARY | SECONDARY |

PORT | RESERVOIR |

(PRI) | AUXILIARY PORTS |

| (TO ACCESSORIES) |

| PURGE |

| RESERVOIR |

| DRAIN VALVE |

PRIMARY

![]() RESERVOIR

RESERVOIR

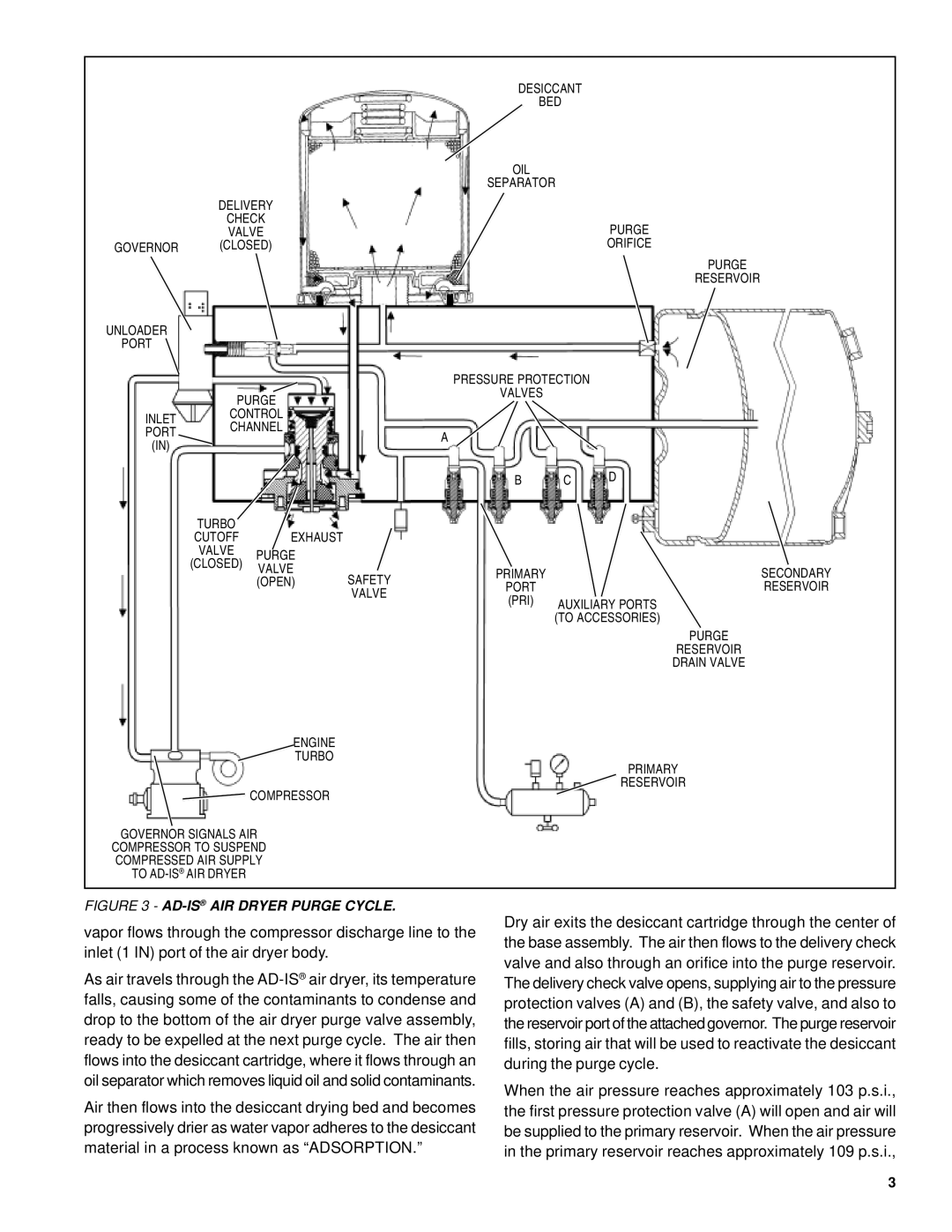

FIGURE 3 - AD-IS® AIR DRYER PURGE CYCLE.

vapor flows through the compressor discharge line to the inlet (1 IN) port of the air dryer body.

As air travels through the

Air then flows into the desiccant drying bed and becomes progressively drier as water vapor adheres to the desiccant material in a process known as “ADSORPTION.”

Dry air exits the desiccant cartridge through the center of the base assembly. The air then flows to the delivery check valve and also through an orifice into the purge reservoir. The delivery check valve opens, supplying air to the pressure protection valves (A) and (B), the safety valve, and also to the reservoir port of the attached governor. The purge reservoir fills, storing air that will be used to reactivate the desiccant during the purge cycle.

When the air pressure reaches approximately 103 p.s.i., the first pressure protection valve (A) will open and air will be supplied to the primary reservoir. When the air pressure in the primary reservoir reaches approximately 109 p.s.i.,

3