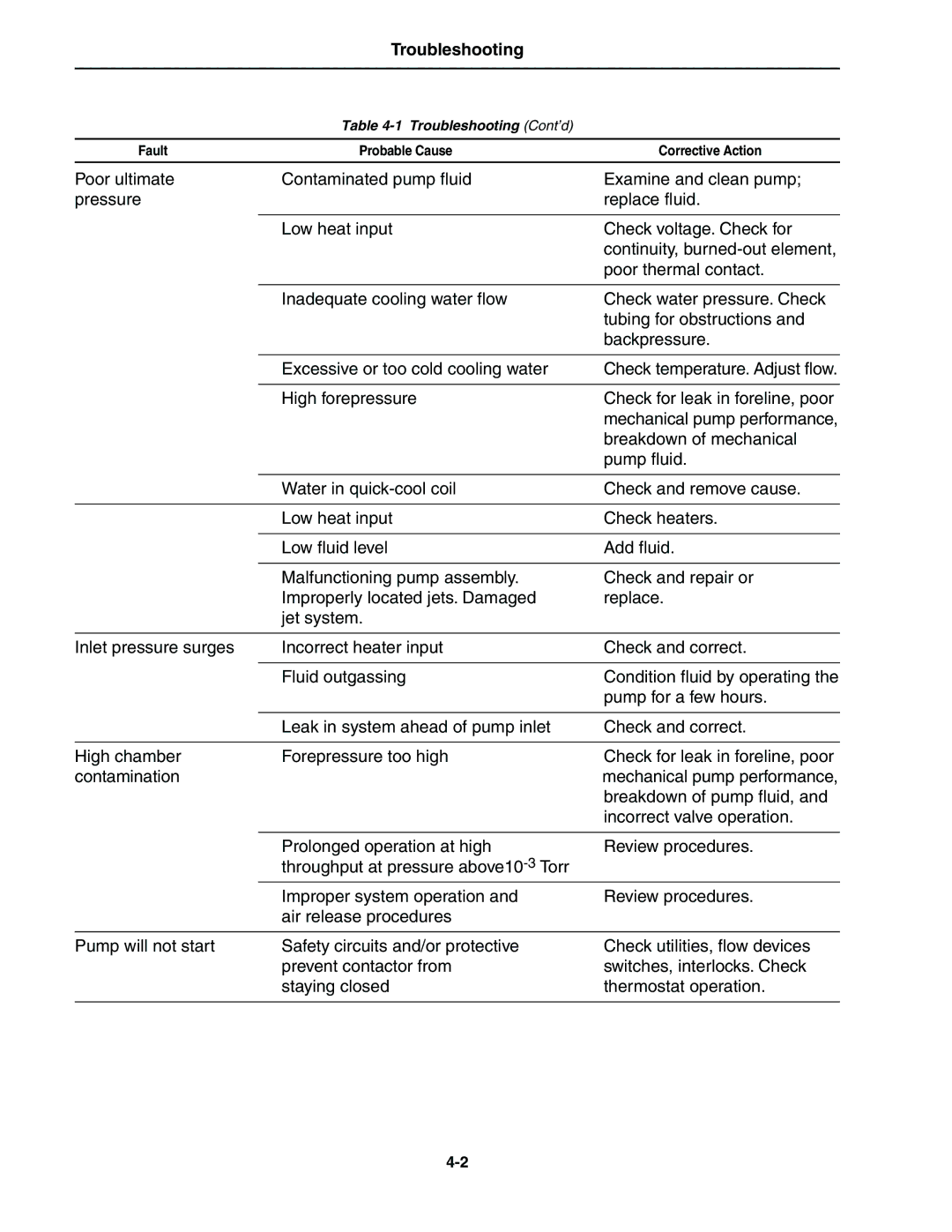

Troubleshooting

Table

Fault | Probable Cause | Corrective Action |

Poor ultimate | Contaminated pump fluid | Examine and clean pump; |

pressure |

| replace fluid. |

|

|

|

| Low heat input | Check voltage. Check for |

|

| continuity, |

|

| poor thermal contact. |

|

|

|

| Inadequate cooling water flow | Check water pressure. Check |

|

| tubing for obstructions and |

|

| backpressure. |

|

|

|

| Excessive or too cold cooling water | Check temperature. Adjust flow. |

|

|

|

| High forepressure | Check for leak in foreline, poor |

|

| mechanical pump performance, |

|

| breakdown of mechanical |

|

| pump fluid. |

|

|

|

| Water in | Check and remove cause. |

|

|

|

| Low heat input | Check heaters. |

|

|

|

| Low fluid level | Add fluid. |

|

|

|

| Malfunctioning pump assembly. | Check and repair or |

| Improperly located jets. Damaged | replace. |

| jet system. |

|

|

|

|

Inlet pressure surges | Incorrect heater input | Check and correct. |

|

|

|

| Fluid outgassing | Condition fluid by operating the |

|

| pump for a few hours. |

|

|

|

| Leak in system ahead of pump inlet | Check and correct. |

|

|

|

High chamber | Forepressure too high | Check for leak in foreline, poor |

contamination |

| mechanical pump performance, |

|

| breakdown of pump fluid, and |

|

| incorrect valve operation. |

|

|

|

| Prolonged operation at high | Review procedures. |

| throughput at pressure |

|

| Improper system operation and | Review procedures. |

| air release procedures |

|

Pump will not start | Safety circuits and/or protective |

| prevent contactor from |

| staying closed |

Check utilities, flow devices switches, interlocks. Check thermostat operation.