WARNING: Be sure to use appropriate | B |

| B1 |

| |||

protective gear and unplug unit. |

| ||

WARNING: Make sure area is well |

| ||

ventilated and free of flammable vapors. |

|

|

|

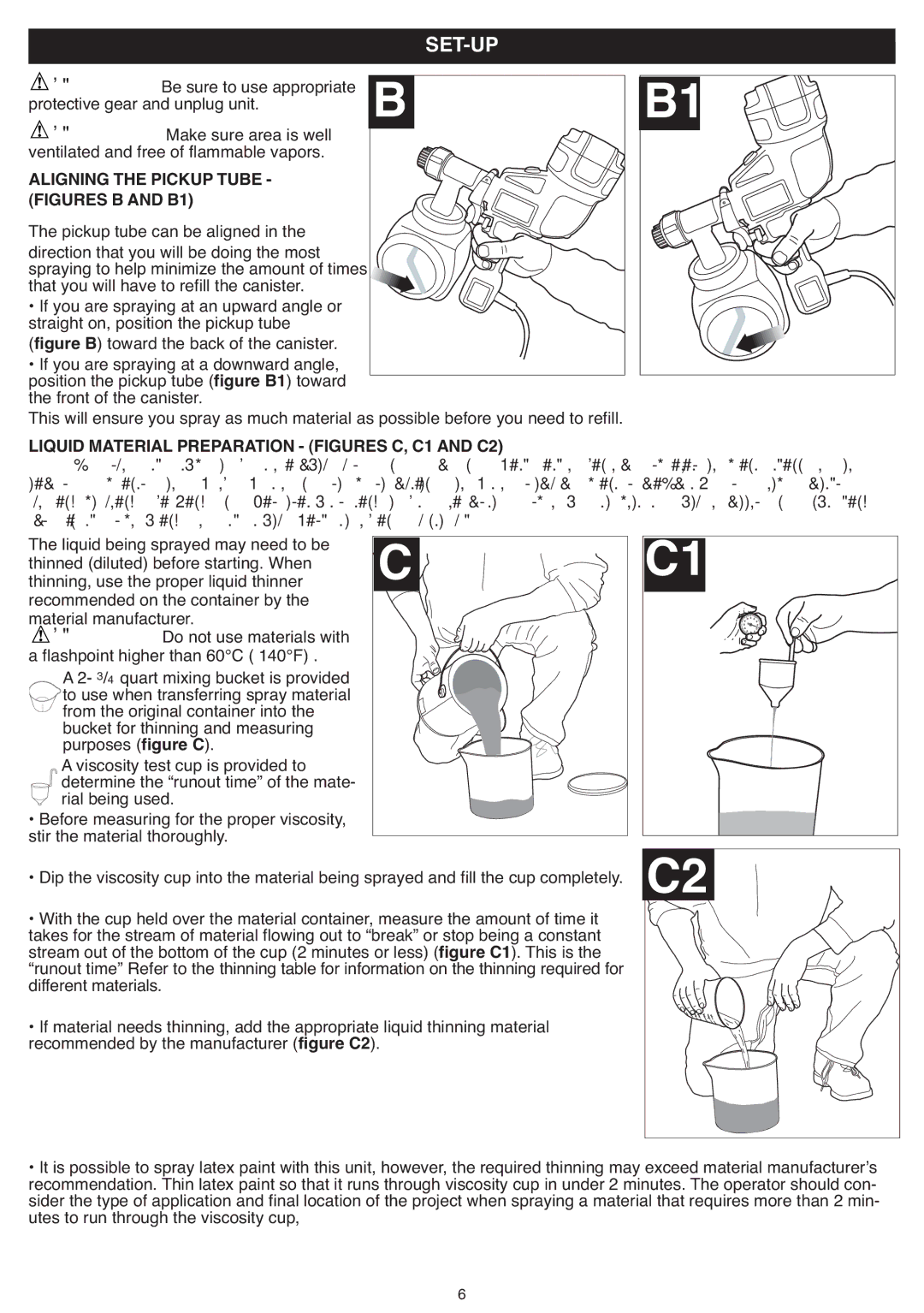

ALIGNING THE PICKUP TUBE - |

|

|

|

(FIGURES B AND B1) |

|

|

|

The pickup tube can be aligned in the |

|

|

|

direction that you will be doing the most |

|

|

|

spraying to help minimize the amount of times |

|

|

|

that you will have to refill the canister. |

|

|

|

• If you are spraying at an upward angle or |

|

|

|

straight on, position the pickup tube |

|

|

|

(figure B) toward the back of the canister. |

|

|

|

• If you are spraying at a downward angle, |

|

|

|

position the pickup tube (figure B1) toward |

|

|

|

the front of the canister. |

|

|

|

This will ensure you spray as much material as possible before you need to refill. |

| ||

LIQUID MATERIAL PREPARATION - (FIGURES C, C1 AND C2) |

| ||

TIP: Make sure the type of material you use can be cleaned with either mineral spirits or paint thinner (for | |||

during pouring, mixing, and viscosity testing of materials to be sprayed to protect your floors and anything | |||

else in the spraying area that you wish to remain untouched. |

| ||

The liquid being sprayed may need to be |

|

|

|

thinned (diluted) before starting. When |

|

|

|

thinning, use the proper liquid thinner |

|

|

|

recommended on the container by the |

|

|

|

material manufacturer. |

|

|

|

WARNING: Do not use materials with |

|

|

|

a flashpoint higher than 60°C ( 140°F) . |

|

|

|

A 2- 3/4 quart mixing bucket is provided |

|

|

|

to use when transferring spray material |

|

|

|

from the original container into the |

|

|

|

bucket for thinning and measuring |

|

|

|

purposes (figure C). |

|

|

|

A viscosity test cup is provided to |

|

|

|

determine the “runout time” of the mate- |

|

|

|

rial being used. |

|

| C2 |

• Before measuring for the proper viscosity, |

|

| |

stir the material thoroughly. |

|

| |

• Dip the viscosity cup into the material being sprayed and fill the cup completely. | |||

• With the cup held over the material container, measure the amount of time it | |||

takes for the stream of material flowing out to “break” or stop being a constant |

| ||

stream out of the bottom of the cup (2 minutes or less) (figure C1). This is the |

| ||

“runout time” Refer to the thinning table for information on the thinning required for |

| ||

different materials. |

|

|

|

• If material needs thinning, add the appropriate liquid thinning material |

| ||

recommended by the manufacturer (figure C2). |

|

| |

•It is possible to spray latex paint with this unit, however, the required thinning may exceed material manufacturerʼs recommendation. Thin latex paint so that it runs through viscosity cup in under 2 minutes. The operator should con- sider the type of application and final location of the project when spraying a material that requires more than 2 min- utes to run through the viscosity cup,

6