399080-02 rev 11/15/02 10:13 AM Page 10

English

IMPORTANT INFORMATION ABOUT

GUARDS

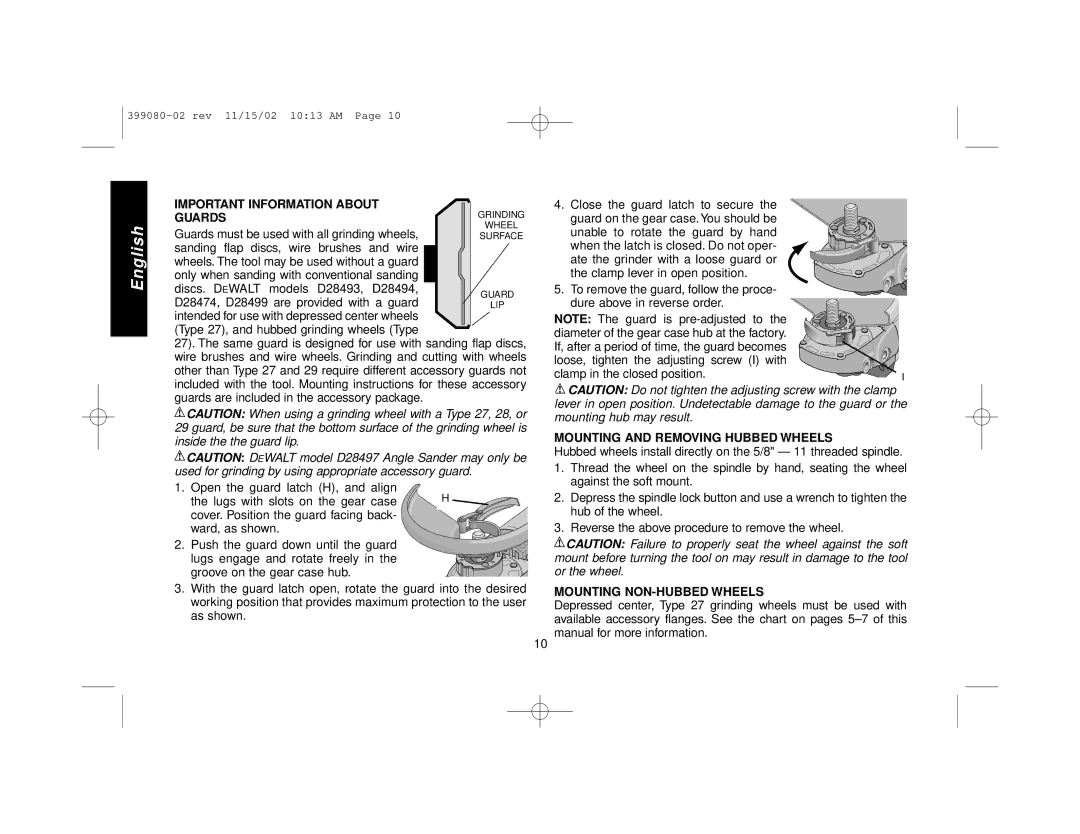

Guards must be used with all grinding wheels, sanding flap discs, wire brushes and wire wheels. The tool may be used without a guard only when sanding with conventional sanding discs. DEWALT models D28493, D28494, D28474, D28499 are provided with a guard intended for use with depressed center wheels (Type 27), and hubbed grinding wheels (Type

27). The same guard is designed for use with sanding flap discs, wire brushes and wire wheels. Grinding and cutting with wheels other than Type 27 and 29 require different accessory guards not included with the tool. Mounting instructions for these accessory guards are included in the accessory package.

![]() CAUTION: When using a grinding wheel with a Type 27, 28, or 29 guard, be sure that the bottom surface of the grinding wheel is inside the the guard lip.

CAUTION: When using a grinding wheel with a Type 27, 28, or 29 guard, be sure that the bottom surface of the grinding wheel is inside the the guard lip.

![]() CAUTION: DEWALT model D28497 Angle Sander may only be used for grinding by using appropriate accessory guard.

CAUTION: DEWALT model D28497 Angle Sander may only be used for grinding by using appropriate accessory guard.

1. Open the guard latch (H), and align |

|

the lugs with slots on the gear case | H |

cover. Position the guard facing back- |

|

| |

ward, as shown. |

|

2. Push the guard down until the guard lugs engage and rotate freely in the groove on the gear case hub.

3.With the guard latch open, rotate the guard into the desired working position that provides maximum protection to the user as shown.

4. Close the guard latch to secure the guard on the gear case. You should be unable to rotate the guard by hand when the latch is closed. Do not oper- ate the grinder with a loose guard or the clamp lever in open position.

5. To remove the guard, follow the proce- dure above in reverse order.

NOTE: The guard is |

|

diameter of the gear case hub at the factory. |

|

If, after a period of time, the guard becomes |

|

loose, tighten the adjusting screw (I) with |

|

clamp in the closed position. | I |

![]() CAUTION: Do not tighten the adjusting screw with the clamp lever in open position. Undetectable damage to the guard or the mounting hub may result.

CAUTION: Do not tighten the adjusting screw with the clamp lever in open position. Undetectable damage to the guard or the mounting hub may result.

MOUNTING AND REMOVING HUBBED WHEELS

Hubbed wheels install directly on the 5/8" — 11 threaded spindle.

1.Thread the wheel on the spindle by hand, seating the wheel against the soft mount.

2.Depress the spindle lock button and use a wrench to tighten the hub of the wheel.

3.Reverse the above procedure to remove the wheel.

![]() CAUTION: Failure to properly seat the wheel against the soft mount before turning the tool on may result in damage to the tool or the wheel.

CAUTION: Failure to properly seat the wheel against the soft mount before turning the tool on may result in damage to the tool or the wheel.

MOUNTING NON-HUBBED WHEELS

Depressed center, Type 27 grinding wheels must be used with available accessory flanges. See the chart on pages

manual for more information.

10