399080-02 rev 11/15/02 10:13 AM Page 11

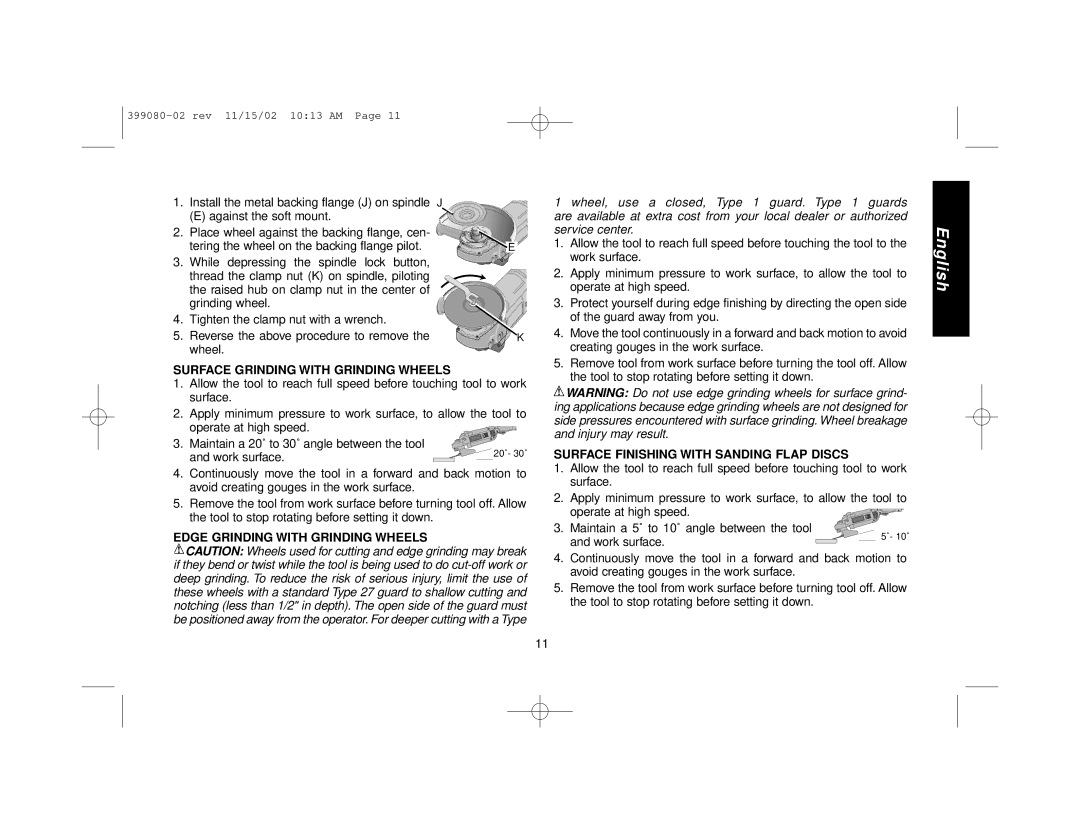

1.Install the metal backing flange (J) on spindle

(E) against the soft mount.

2.Place wheel against the backing flange, cen- tering the wheel on the backing flange pilot.

3.While depressing the spindle lock button, thread the clamp nut (K) on spindle, piloting the raised hub on clamp nut in the center of grinding wheel.

4.Tighten the clamp nut with a wrench.

5.Reverse the above procedure to remove the wheel.

J ![]()

![]()

![]() E

E

K

1 wheel, use a closed, Type 1 guard. Type 1 guards are available at extra cost from your local dealer or authorized service center.

1. | Allow the tool to reach full speed before touching the tool to the |

| work surface. |

2. | Apply minimum pressure to work surface, to allow the tool to |

| operate at high speed. |

3. | Protect yourself during edge finishing by directing the open side |

| of the guard away from you. |

4. | Move the tool continuously in a forward and back motion to avoid |

| creating gouges in the work surface. |

5. | Remove tool from work surface before turning the tool off. Allow |

English

SURFACE GRINDING WITH GRINDING WHEELS

1.Allow the tool to reach full speed before touching tool to work surface.

2.Apply minimum pressure to work surface, to allow the tool to

operate at high speed.

3. Maintain a 20˚ to 30˚ angle between the tool | 20˚- 30˚ |

and work surface. |

4.Continuously move the tool in a forward and back motion to avoid creating gouges in the work surface.

5.Remove the tool from work surface before turning tool off. Allow the tool to stop rotating before setting it down.

EDGE GRINDING WITH GRINDING WHEELS

![]() CAUTION: Wheels used for cutting and edge grinding may break if they bend or twist while the tool is being used to do

CAUTION: Wheels used for cutting and edge grinding may break if they bend or twist while the tool is being used to do

the tool to stop rotating before setting it down. |

![]() WARNING: Do not use edge grinding wheels for surface grind- ing applications because edge grinding wheels are not designed for side pressures encountered with surface grinding. Wheel breakage and injury may result.

WARNING: Do not use edge grinding wheels for surface grind- ing applications because edge grinding wheels are not designed for side pressures encountered with surface grinding. Wheel breakage and injury may result.

SURFACE FINISHING WITH SANDING FLAP DISCS

1.Allow the tool to reach full speed before touching tool to work surface.

2.Apply minimum pressure to work surface, to allow the tool to

operate at high speed.![]()

![]()

![]()

![]()

![]()

![]()

![]() 3. Maintain a 5˚ to 10˚ angle between the tool

3. Maintain a 5˚ to 10˚ angle between the tool

and work surface. | 5˚- 10˚ |

|

4.Continuously move the tool in a forward and back motion to avoid creating gouges in the work surface.

5.Remove the tool from work surface before turning tool off. Allow the tool to stop rotating before setting it down.

11