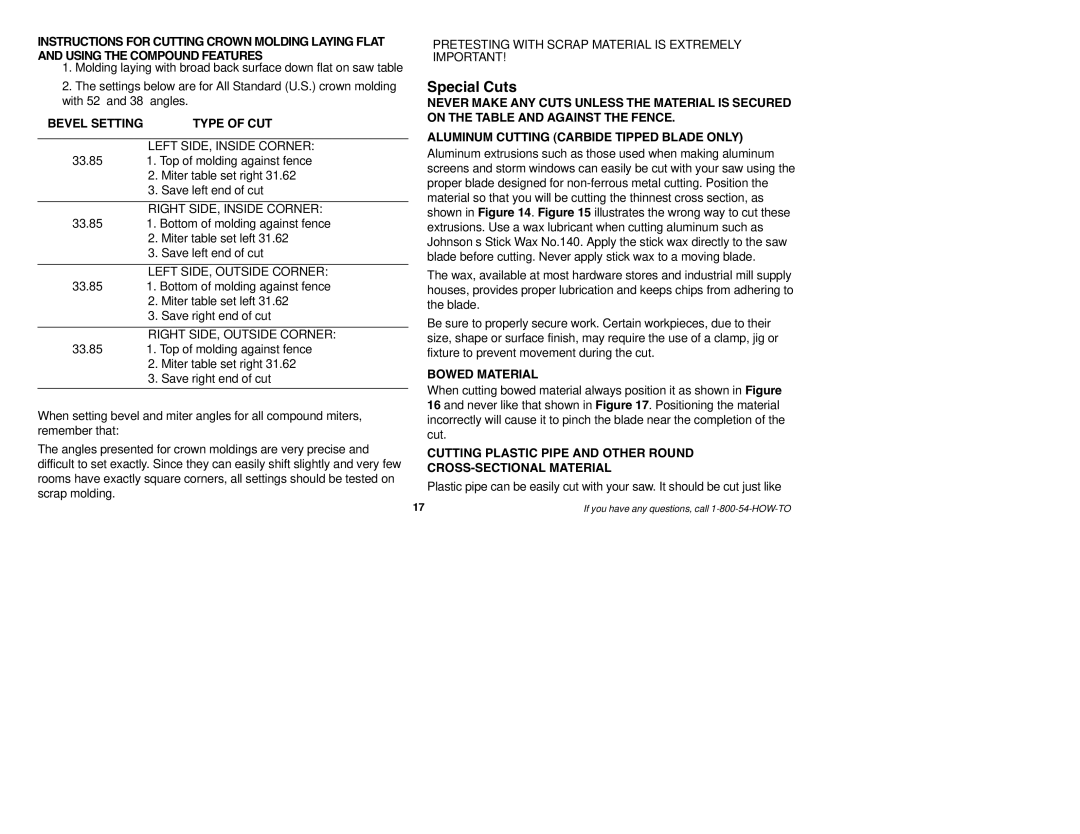

INSTRUCTIONS FOR CUTTING CROWN MOLDING LAYING FLAT | PRETESTING WITH SCRAP MATERIAL IS EXTREMELY |

AND USING THE COMPOUND FEATURES | IMPORTANT! |

1. Molding laying with broad back surface down flat on saw table |

|

2.The settings below are for All Standard (U.S.) crown molding with 52° and 38° angles.

BEVEL SETTING | TYPE OF CUT |

LEFT SIDE, INSIDE CORNER:

33.85° 1. Top of molding against fence

2.Miter table set right 31.62°

3.Save left end of cut

RIGHT SIDE, INSIDE CORNER:

33.85° 1. Bottom of molding against fence

2.Miter table set left 31.62°

3.Save left end of cut

LEFT SIDE, OUTSIDE CORNER:

33.85° 1. Bottom of molding against fence

2.Miter table set left 31.62°

3.Save right end of cut

RIGHT SIDE, OUTSIDE CORNER:

33.85° 1. Top of molding against fence

2.Miter table set right 31.62°

3.Save right end of cut

When setting bevel and miter angles for all compound miters, remember that:

The angles presented for crown moldings are very precise and difficult to set exactly. Since they can easily shift slightly and very few rooms have exactly square corners, all settings should be tested on scrap molding.

Special Cuts

NEVER MAKE ANY CUTS UNLESS THE MATERIAL IS SECURED ON THE TABLE AND AGAINST THE FENCE.

ALUMINUM CUTTING (CARBIDE TIPPED BLADE ONLY)

Aluminum extrusions such as those used when making aluminum screens and storm windows can easily be cut with your saw using the proper blade designed for

The wax, available at most hardware stores and industrial mill supply houses, provides proper lubrication and keeps chips from adhering to the blade.

Be sure to properly secure work. Certain workpieces, due to their size, shape or surface finish, may require the use of a clamp, jig or fixture to prevent movement during the cut.

BOWED MATERIAL

When cutting bowed material always position it as shown in Figure 16 and never like that shown in Figure 17. Positioning the material incorrectly will cause it to pinch the blade near the completion of the cut.

CUTTING PLASTIC PIPE AND OTHER ROUND

Plastic pipe can be easily cut with your saw. It should be cut just like

17 | If you have any questions, call |