90503227 ISD600 Impact Driver 6/15/06 12:52 PM Page 5

4. Let the tool charge initially for 9 hours.

![]() WARNING: When disconnecting the tool from the charger, be sure to unplug the charger from the outlet first, then disconnect the charger cord from the tool cradle.

WARNING: When disconnecting the tool from the charger, be sure to unplug the charger from the outlet first, then disconnect the charger cord from the tool cradle.

Important Charging Notes

1.After normal usage, your tool should be fully charged in 3 to 9 hours. If the batteries are run down completely, it may take up to 9 hours to become fully charged. Your tool was sent from the factory in an uncharged condition. Before attempting to use it, it must be charged for at least 9 hours.

2.DO NOT charge the batteries in an air temperature below 40°F (4,5 °C) or above 105°F (+40,5 °C). This is important and will prevent serious damage to the batteries. Longest life and best performance can be obtained if batteries are charged when air temperature is about 75°F.

3.While charging, the charger may hum and become warm to touch. This is a normal condition and does not indicate a problem.

4.If the batteries do not charge properly:

(1)Check current at receptacle by plugging in a lamp or other appliance.

(2)Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights.

(3)Move charger and tool to a surrounding air temperature of above 40 degree F (4,5°C) or below 105 degree F (+40,5°C).

(4)If the receptacle and temperature are okay, and you do not get proper charging, refer to your warranty.

5.The tool should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE using product with its batteries in a depleted condition.

6.To prolong battery life, avoid leaving on charge for extended periods of time (over 30 days without use). Although overcharging is not a safety concern, it can significantly reduce overall battery life.

7.The batteries will reach optimum performance after being recharged 5 times during normal usage. There is no need to run the batteries down completely before recharging.

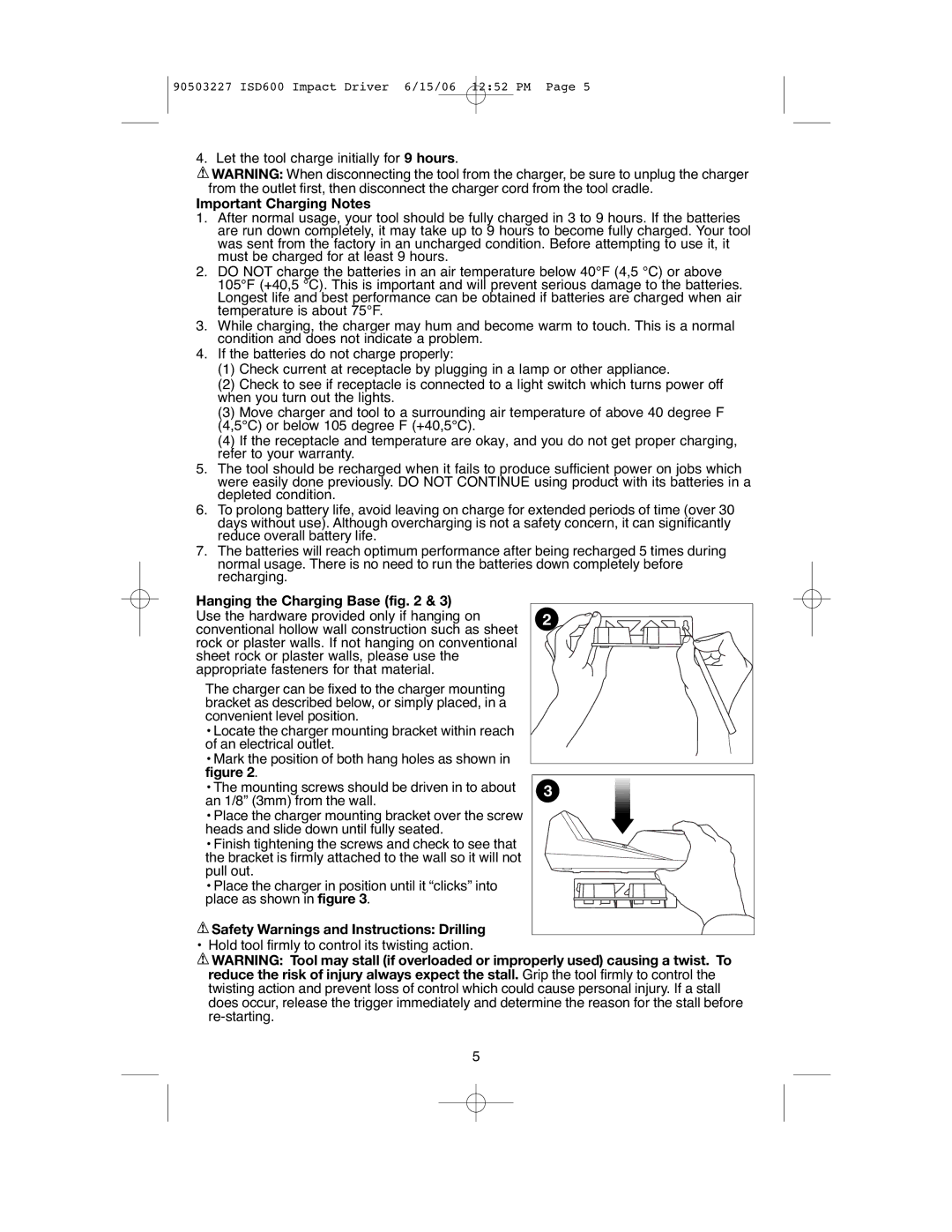

Hanging the Charging Base (fig. 2 & 3) |

|

Use the hardware provided only if hanging on | 2 |

conventional hollow wall construction such as sheet |

|

rock or plaster walls. If not hanging on conventional |

|

sheet rock or plaster walls, please use the |

|

appropriate fasteners for that material. |

|

The charger can be fixed to the charger mounting |

|

bracket as described below, or simply placed, in a |

|

convenient level position. |

|

• Locate the charger mounting bracket within reach |

|

of an electrical outlet. |

|

• Mark the position of both hang holes as shown in |

|

figure 2. |

|

| |

• The mounting screws should be driven in to about | 3 |

an 1/8” (3mm) from the wall. |

|

• Place the charger mounting bracket over the screw |

|

heads and slide down until fully seated. |

|

• Finish tightening the screws and check to see that |

|

the bracket is firmly attached to the wall so it will not |

|

pull out. |

|

• Place the charger in position until it “clicks” into |

|

place as shown in figure 3. |

|

Safety Warnings and Instructions: Drilling

Safety Warnings and Instructions: Drilling

• Hold tool firmly to control its twisting action.

![]() WARNING: Tool may stall (if overloaded or improperly used) causing a twist. To reduce the risk of injury always expect the stall. Grip the tool firmly to control the twisting action and prevent loss of control which could cause personal injury. If a stall does occur, release the trigger immediately and determine the reason for the stall before

WARNING: Tool may stall (if overloaded or improperly used) causing a twist. To reduce the risk of injury always expect the stall. Grip the tool firmly to control the twisting action and prevent loss of control which could cause personal injury. If a stall does occur, release the trigger immediately and determine the reason for the stall before

5