Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC power. This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check the power supply.

OPERATION Save these instructions

CAUTION: Always wear eye protection while operating this power tool.

CAUTION: Always wear eye protection while operating this power tool.

NOTE: Before cutting any type of material, be sure it is firmly anchored or clamped to prevent slipping.

•Place blade lightly against work to be cut.

•Switch on saw motor before applying pressure.

•Always hold saw firmly with both hands while cutting as shown in Figure 1. Whenever possible, the saw shoe must be held firmly against the material being cut. This will prevent the saw from jumping or vibrating and minimize blade breakage.

Switch (on-off) (FIGURE 2)

Depress the trigger switch to turn tool “ON”. Releasing the trigger turns the tool “OFF” NOTE: This tool has no provision to lock the switch in the ON position, and should never be locked in the ON position by any other means.

VARIABLE SPEED SELECTOR WHEEL (FIGURE 3)

The variable speed selector wheel offers a choice of speeds for greatly improved cutting rates in various materials. To select a slower speed for operating the saw, rotate the wheel to a low number on the dial. To select a higher speed, rotate the wheel to a higher number.

TWO-SPEED (DUAL RANGE) SWITCH (FIGURE 3A) RS601 only

The 2-speed selector offers a choice of speeds for greatly improved cutting rates in various materials. Note that the High-Speed setting is more efficient in softer materials such as wood, while the Low-Speed is best for cutting metals.

LOW SPEED (Move slide switch to show 1). For cutting sheet metal, metal pipe, metal conduit, etc.

HIGH SPEED (Move slide switch to show 2). For cutting wood, plastic, composition boards and other similar materials.

Blade Clamp release lever (Figure 4)

CAUTION: Laceration Hazard. TURN OFF AND unplug from power supply when changing blades.

To install blade into saw:

1. Lift the blade clamp release lever to its full open position as shown in Figure 4.

2. Insert blade shank from the front locating hole in blade over pin on reciprocating shaft.

3. Close blade clamp release lever.

4. Check to ensure blade is secure before cutting. To remove blade from saw:

1. Open blade clamp release lever to its full open position.

2. Remove blade.

ADJUSTABLE SHOE (FIGURE 5)

CAUTION: TURN OFF AND UNPLUG SAW.

CAUTION: TURN OFF AND UNPLUG SAW.

The shoe will adjust to limit the depth of cut. Hold the saw with the underside facing up. Push the button (shown in Figure 5) on the hand grip and slide the shoe out to one of the three settings and release the button.

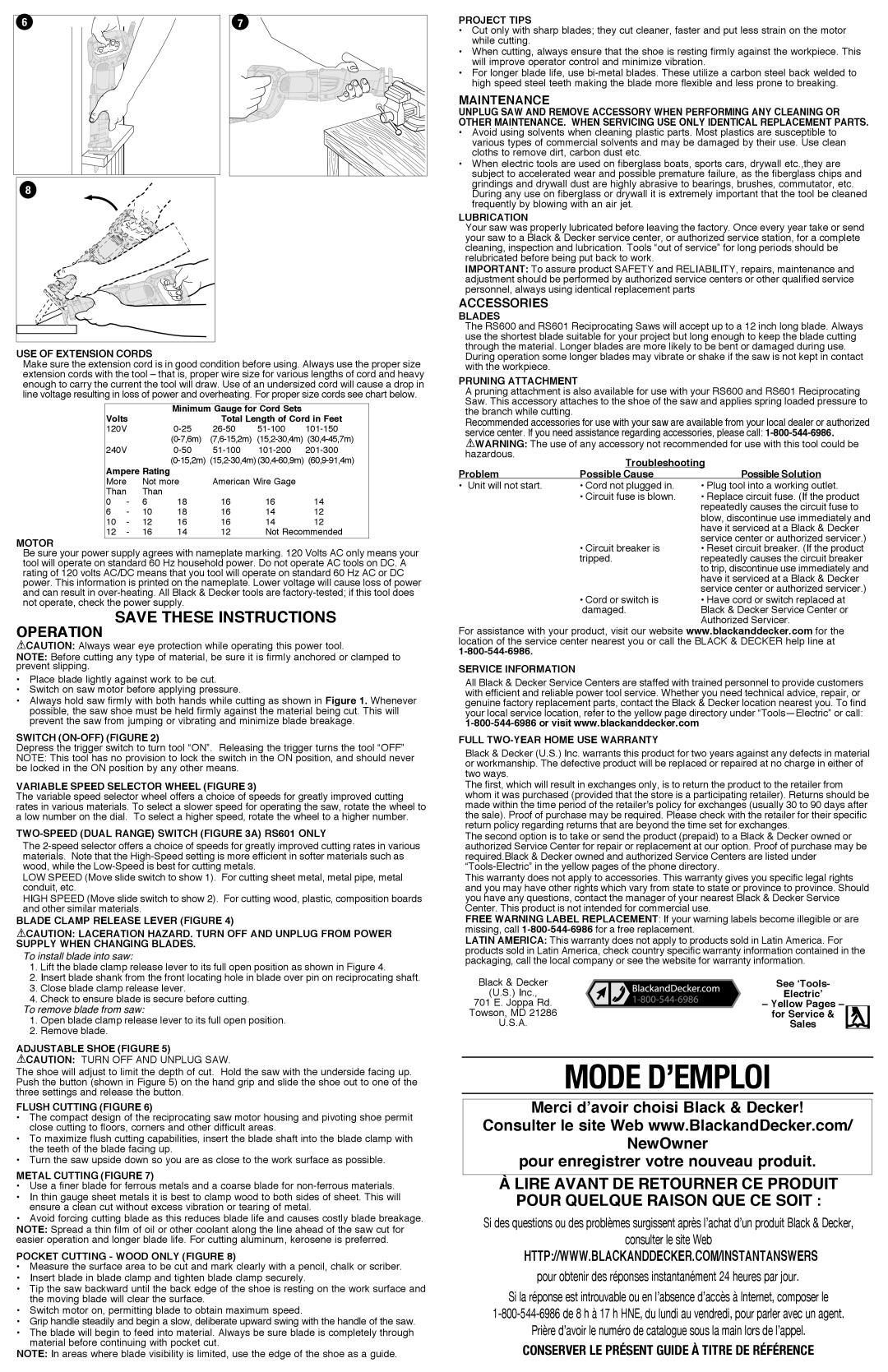

Flush Cutting (FIGURE 6)

• The compact design of the reciprocating saw motor housing and pivoting shoe permit close cutting to floors, corners and other difficult areas.

• To maximize flush cutting capabilities, insert the blade shaft into the blade clamp with the teeth of the blade facing up.

• Turn the saw upside down so you are as close to the work surface as possible.

Metal Cutting (Figure 7)

• Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials.

• In thin gauge sheet metals it is best to clamp wood to both sides of sheet. This will ensure a clean cut without excess vibration or tearing of metal.

• Avoid forcing cutting blade as this reduces blade life and causes costly blade breakage. NOTE: Spread a thin film of oil or other coolant along the line ahead of the saw cut for easier operation and longer blade life. For cutting aluminum, kerosene is preferred.

Pocket Cutting - Wood Only (FIGURE 8)

• Measure the surface area to be cut and mark clearly with a pencil, chalk or scriber.

• Insert blade in blade clamp and tighten blade clamp securely.

• Tip the saw backward until the back edge of the shoe is resting on the work surface and the moving blade will clear the surface.

• Switch motor on, permitting blade to obtain maximum speed.

• Grip handle steadily and begin a slow, deliberate upward swing with the handle of the saw.

• The blade will begin to feed into material. Always be sure blade is completely through material before continuing with pocket cut.

NOTE: In areas where blade visibility is limited, use the edge of the shoe as a guide.

• Circuit breaker is | service center or authorized servicer.) |

• Reset circuit breaker. (If the product |

tripped. | repeatedly causes the circuit breaker |

| to trip, discontinue use immediately and |

| have it serviced at a Black & Decker |

• Cord or switch is | service center or authorized servicer.) |

• Have cord or switch replaced at |

damaged. | Black & Decker Service Center or |

| Authorized Servicer. |

For assistance with your product, visit our website www.blackanddecker.com for the location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location nearest you. To find your local service location, refer to the yellow page directory under “Tools—Electric” or call:

1-800-544-6986 or visit www.blackanddecker.com

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or replacement at our option. Proof of purchase may be required.Black & Decker owned and authorized Service Centers are listed under “Tools-Electric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary from state to state or province to province. Should you have any questions, contact the manager of your nearest Black & Decker Service Center. This product is not intended for commercial use.

free warning label replacement: If your warning labels become illegible or are missing, call 1-800-544-6986for a free replacement.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, check country specific warranty information contained in the packaging, call the local company or see the website for warranty information.

Black & Decker | See ‘Tools- |

(U.S.) Inc., | Electric’ |

701 E. Joppa Rd. | – Yellow Pages – |

Towson, MD 21286 | for Service & |

U.S.A. | Sales |

MODE D’EMPLOI

Merci d’avoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/

NewOwner

pour enregistrer votre nouveau produit.

àLIRE avant de retourner ce produit pour quelque raison que ce soit :

Si des questions ou des problèmes surgissent après l’achat d’un produit Black & Decker,

consulter le site Web

http://www.blackanddecker.com/instantanswers

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en l’absence d’accès à Internet, composer le

1-800-544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière d’avoir le numéro de catalogue sous la main lors de l’appel.

CONSERVER LE PRÉSENT GUIDE À TITRE DE RÉFÉRENCE