CLEANING & MAINTENANCE | INFRARED/RADIANT COMPACT BROILER |

VENTILATION

![]() WARNING

WARNING

Improper ventilation can result in personal injury or death. Ventilation, which fails to properly remove flue products, can cause headaches, drowsiness, nausea, or could result in death.

The flue vent, located at the top of the unit, must not be blocked or covered at any time.

All gas appliances must be installed in such a manner that the flow of combustion and ventilation air is not obstructed. Provisions for adequate air supply must be provided.

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be covered by the warranty.

Do not obstruct the front of the broiler since combustion air enters through this area. Be sure to inspect and clean the ventilation system according to the ventilation equipment manufacturer’s instructions.

If a ventilation canopy is used, it is recommended that the canopy extend 6" past the broiler and that the bottom edge be located 6'6" from the floor. Filters should be installed at an angle of 45° or more from the horizontal. This position prevents dripping grease and facilitates collecting the

A strong exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may extinguish pilot flames. Fresh air openings approximately equal to the fan area will relieve such a vacuum. The exhaust fan should be installed at least 2" above the vent opening on the top of the broiler.

If the broiler is connected directly to an outside flue, a CSA

In case of unsatisfactory performance by any gas appliance, check the appliance with the exhaust fan turned OFF. Do this only long enough to check whether doing so corrects any problems with equipment performance. Then turn the exhaust fan back on and let it run to remove any exhaust that may have accumulated during the test.

GAS SUPPLY

The broiler is

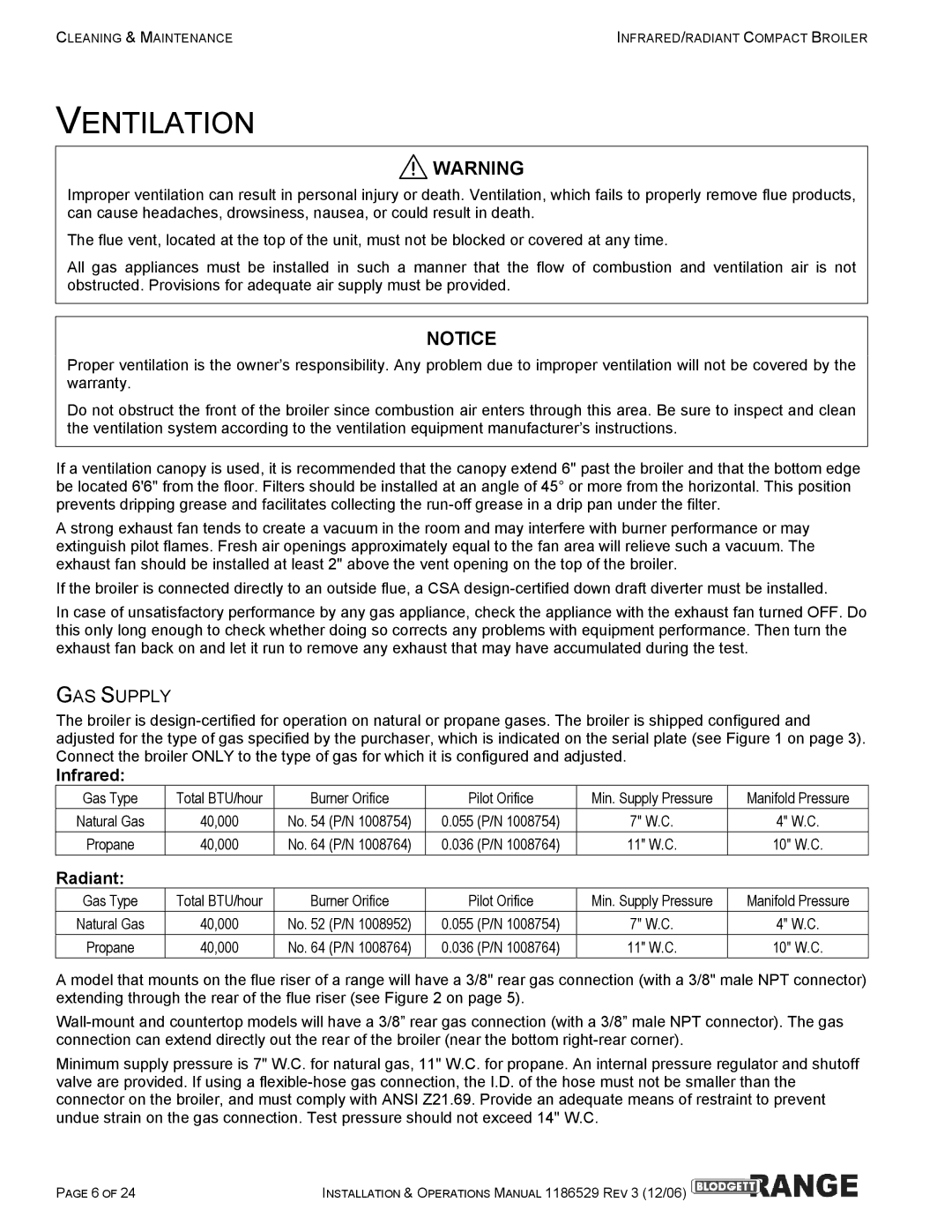

Infrared:

Gas Type | Total BTU/hour | Burner Orifice | Pilot Orifice | Min. Supply Pressure | Manifold Pressure |

Natural Gas | 40,000 | No. 54 (P/N 1008754) | 0.055 (P/N 1008754) | 7" W.C. | 4" W.C. |

Propane | 40,000 | No. 64 (P/N 1008764) | 0.036 (P/N 1008764) | 11" W.C. | 10" W.C. |

Radiant:

Gas Type | Total BTU/hour | Burner Orifice | Pilot Orifice | Min. Supply Pressure | Manifold Pressure |

Natural Gas | 40,000 | No. 52 (P/N 1008952) | 0.055 (P/N 1008754) | 7" W.C. | 4" W.C. |

Propane | 40,000 | No. 64 (P/N 1008764) | 0.036 (P/N 1008764) | 11" W.C. | 10" W.C. |

A model that mounts on the flue riser of a range will have a 3/8" rear gas connection (with a 3/8" male NPT connector) extending through the rear of the flue riser (see Figure 2 on page 5).

Minimum supply pressure is 7" W.C. for natural gas, 11" W.C. for propane. An internal pressure regulator and shutoff valve are provided. If using a

PAGE 6 OF 24 | INSTALLATION & OPERATIONS MANUAL 1186529 REV 3 (12/06) |