ASSEMBLY

ASSEMBLY

DRIVELINE CLAMP CONE YOKE OPERATING INSTRUCTIONS

Loosen the yoke clamp cone with a 11/16” (17mm)

wrench and remove the cone from yoke. Slide yoke onto the shaft and align hole for clamping cone with annular groove of gearbox shaft. Reinstall cone and tighten (75

NOTE: The clamping cone is serviced only as a complete assembly. Do not attempt to disassemble the clamping cone

FRONT AND REAR DEFLECTORS (Standard Equipment)

CHAIN GUARDS (Optional Equipment at extra cost)

Front and Rear

DEFLECTORS: Front and Rear Deflectors (Standard Equipment) are recommended for the average user and will provide protection from thrown objects with proper operation under normal conditions. Deflectors must be maintained in good repair or replaced after no more than two inches of wear off lower edge.

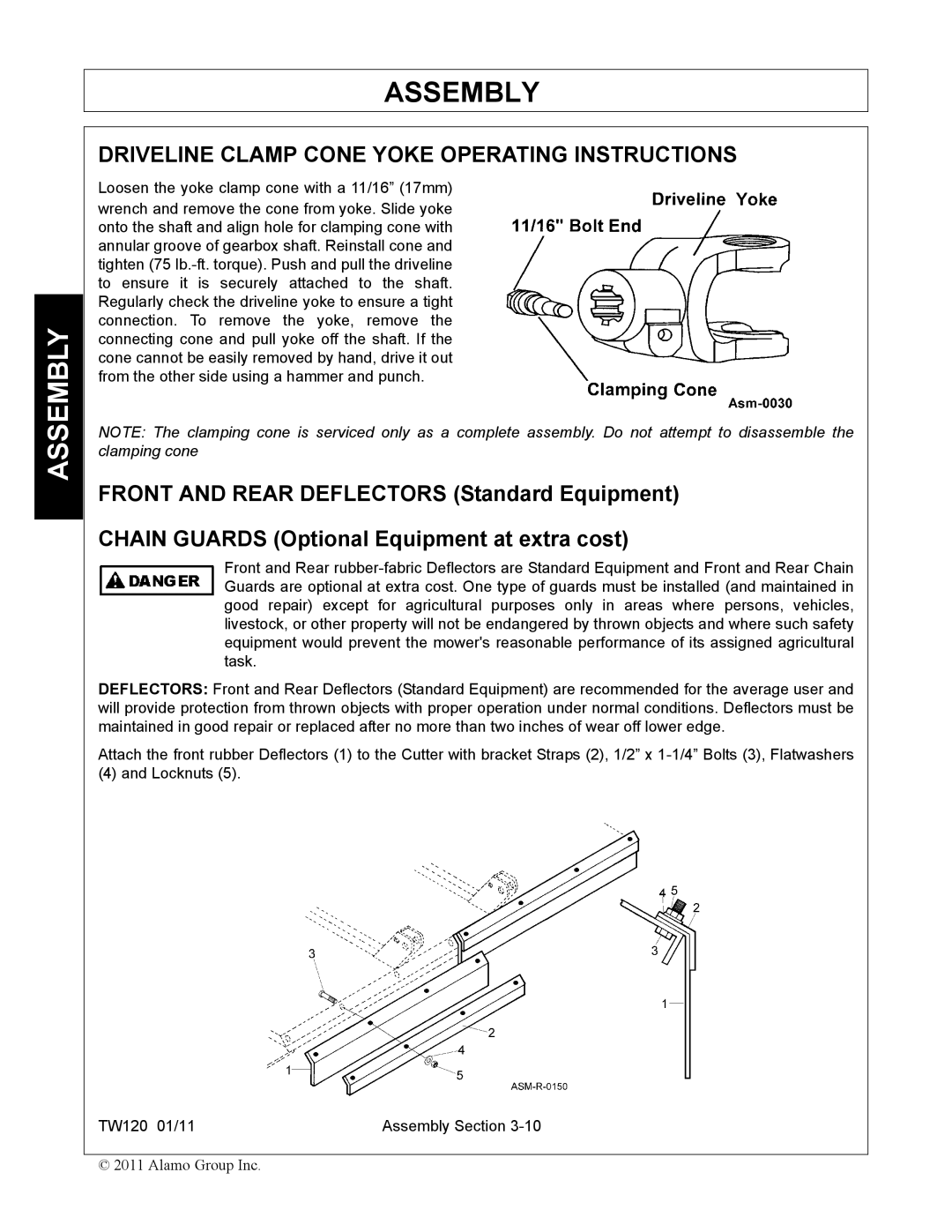

Attach the front rubber Deflectors (1) to the Cutter with bracket Straps (2), 1/2” x

(4) and Locknuts (5).

TW120 01/11 | Assembly Section |

© 2011 Alamo Group Inc.