MAINTENANCE/SERVICE

Engine Air Filter

It is very important that air filter service be performed accord- ing to the maintenance schedule. Refer to the separate Engine Owner’s Manual for inspection and cleaning instructions.

IMPORTANT: Never run engine without air filter assembly prop-

erly installed.

Carburetor Adjustment

WARNING

Do not tamper with the engine governor screw which is

WARNING

The temperature of the muffler and adjacent engine areas may exceed 150oF (65oC). Contact may cause burns. Avoid these areas. Remove the spark plug lead and ground the lead to the engine to prevent accidental starts and fires.

Failure to do this could cause personal injury.

If the engine is running poorly or has low power while tilling, an adjustment to the carburetor may solve the problem. However, first inspect and service the spark plug and the air filter before making a carburetor adjustment. If the engine continues to run poorly (and the fuel mixture is fresh), proceed to the following carburetor adjustment instructions.

This

Prior to Carburetor Adjustment:

•Let engine cool for 30 minutes before continuing.

•From the operator’s position behind the handlebars, lay the machine down on its left side (muffler side).

Carburetor Adjustment:

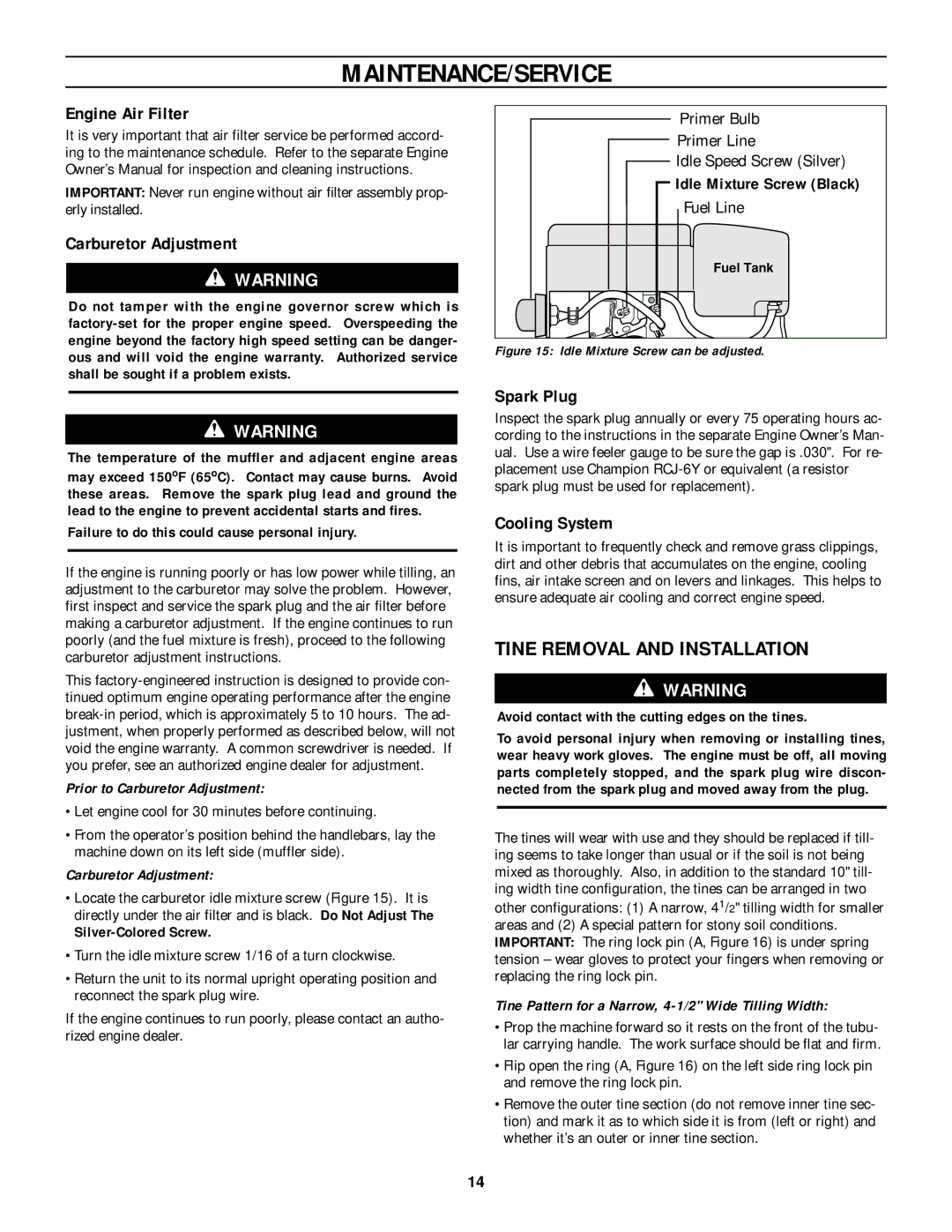

•Locate the carburetor idle mixture screw (Figure 15). It is directly under the air filter and is black. Do Not Adjust The

Silver-Colored Screw.

•Turn the idle mixture screw 1/16 of a turn clockwise.

•Return the unit to its normal upright operating position and reconnect the spark plug wire.

If the engine continues to run poorly, please contact an autho- rized engine dealer.

Primer Bulb

Primer Line

Idle Speed Screw (Silver)

Idle Mixture Screw (Black)

Fuel Line

Fuel Tank

Figure 15: Idle Mixture Screw can be adjusted.

Spark Plug

Inspect the spark plug annually or every 75 operating hours ac- cording to the instructions in the separate Engine Owner’s Man- ual. Use a wire feeler gauge to be sure the gap is .030". For re- placement use Champion

Cooling System

It is important to frequently check and remove grass clippings, dirt and other debris that accumulates on the engine, cooling fins, air intake screen and on levers and linkages. This helps to ensure adequate air cooling and correct engine speed.

TINE REMOVAL AND INSTALLATION

WARNING

Avoid contact with the cutting edges on the tines.

To avoid personal injury when removing or installing tines, wear heavy work gloves. The engine must be off, all moving parts completely stopped, and the spark plug wire discon- nected from the spark plug and moved away from the plug.

The tines will wear with use and they should be replaced if till- ing seems to take longer than usual or if the soil is not being mixed as thoroughly. Also, in addition to the standard 10" till- ing width tine configuration, the tines can be arranged in two other configurations: (1) A narrow, 41/2" tilling width for smaller areas and (2) A special pattern for stony soil conditions. IMPORTANT: The ring lock pin (A, Figure 16) is under spring tension – wear gloves to protect your fingers when removing or replacing the ring lock pin.

Tine Pattern for a Narrow, 4-1/2" Wide Tilling Width:

•Prop the machine forward so it rests on the front of the tubu- lar carrying handle. The work surface should be flat and firm.

•Flip open the ring (A, Figure 16) on the left side ring lock pin and remove the ring lock pin.

•Remove the outer tine section (do not remove inner tine sec- tion) and mark it as to which side it is from (left or right) and whether it’s an outer or inner tine section.

14