Masonry Cutting Guard

Assembly

A type 27 grinding wheel ! WARNING guard may not be used for

all tool operations. Do not discard guard when not in use. Always reinstall wheel guard when converting back to grinding operations.

To improve ergonomics of your grinder when cutting masonry, gearbox must be rotated relative to the position of the switch as the tool was assembled at the factory.

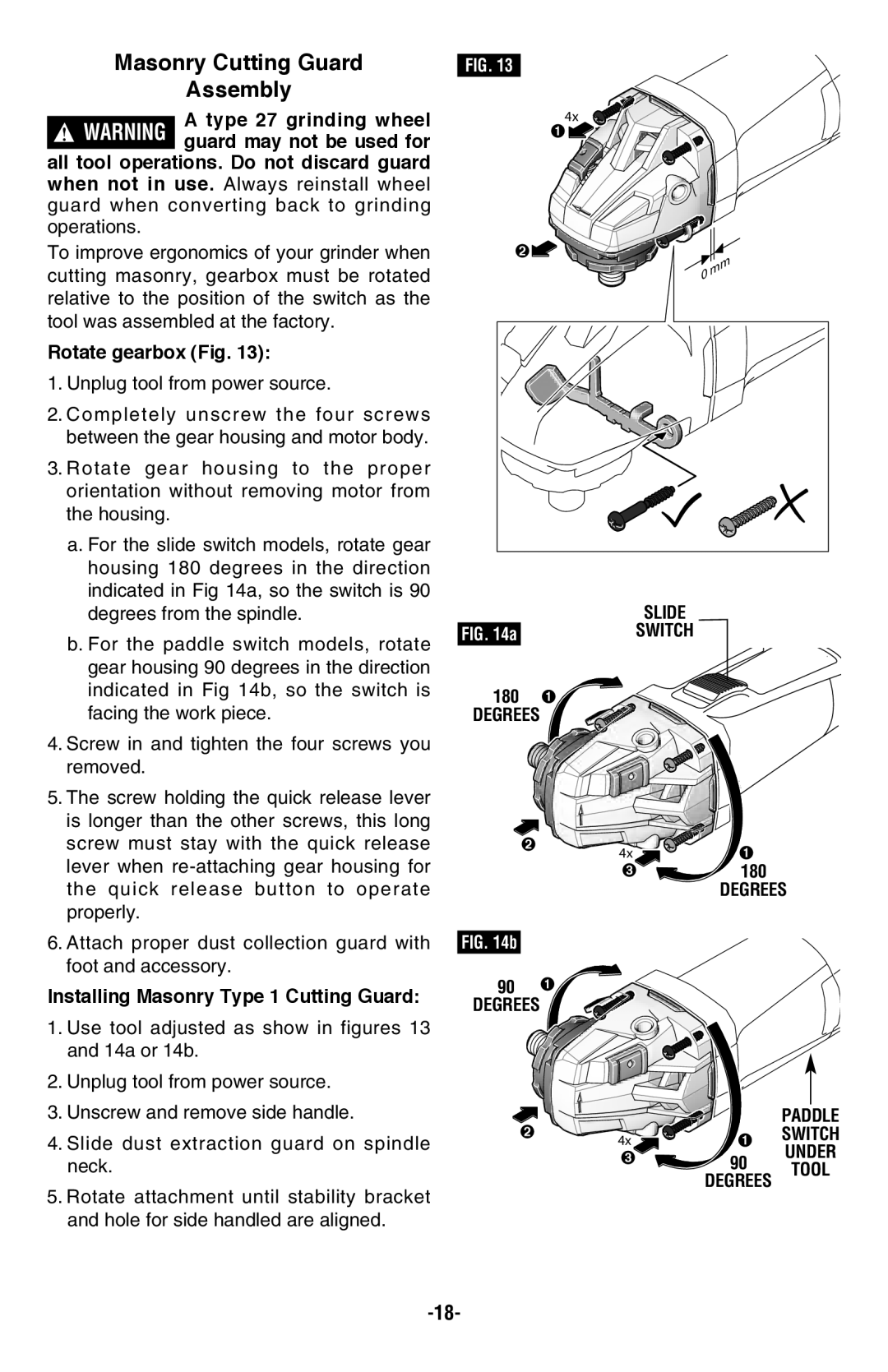

Rotate gearbox (Fig. 13):

1.Unplug tool from power source.

2.Completely unscrew the four screws between the gear housing and motor body.

3.Rotate gear housing to the proper orientation without removing motor from the housing.

a.For the slide switch models, rotate gear housing 180 degrees in the direction indicated in Fig 14a, so the switch is 90 degrees from the spindle.

b.For the paddle switch models, rotate gear housing 90 degrees in the direction indicated in Fig 14b, so the switch is facing the work piece.

4.Screw in and tighten the four screws you removed.

5.The screw holding the quick release lever is longer than the other screws, this long screw must stay with the quick release lever when

6.Attach proper dust collection guard with foot and accessory.

Installing Masonry Type 1 Cutting Guard:

1.Use tool adjusted as show in figures 13 and 14a or 14b.

2.Unplug tool from power source.

3.Unscrew and remove side handle.

4.Slide dust extraction guard on spindle neck.

5.Rotate attachment until stability bracket and hole for side handled are aligned.

FIG. 13

4x

FIG. 14a

180![]()

DEGREES

FIG. 14b

90![]()

DEGREES

SLIDE

SWITCH

4x ![]()

![]()

180

DEGREES

| PADDLE |

4x | SWITCH |

| UNDER |

90 | TOOL | |

DEGREES | ||

|