6.Screw in side handle to secure stability bracket between the tool housing and handle.

7.Adjust guard to desired depth of cut.

TO REMOVE: Reverse procedure.

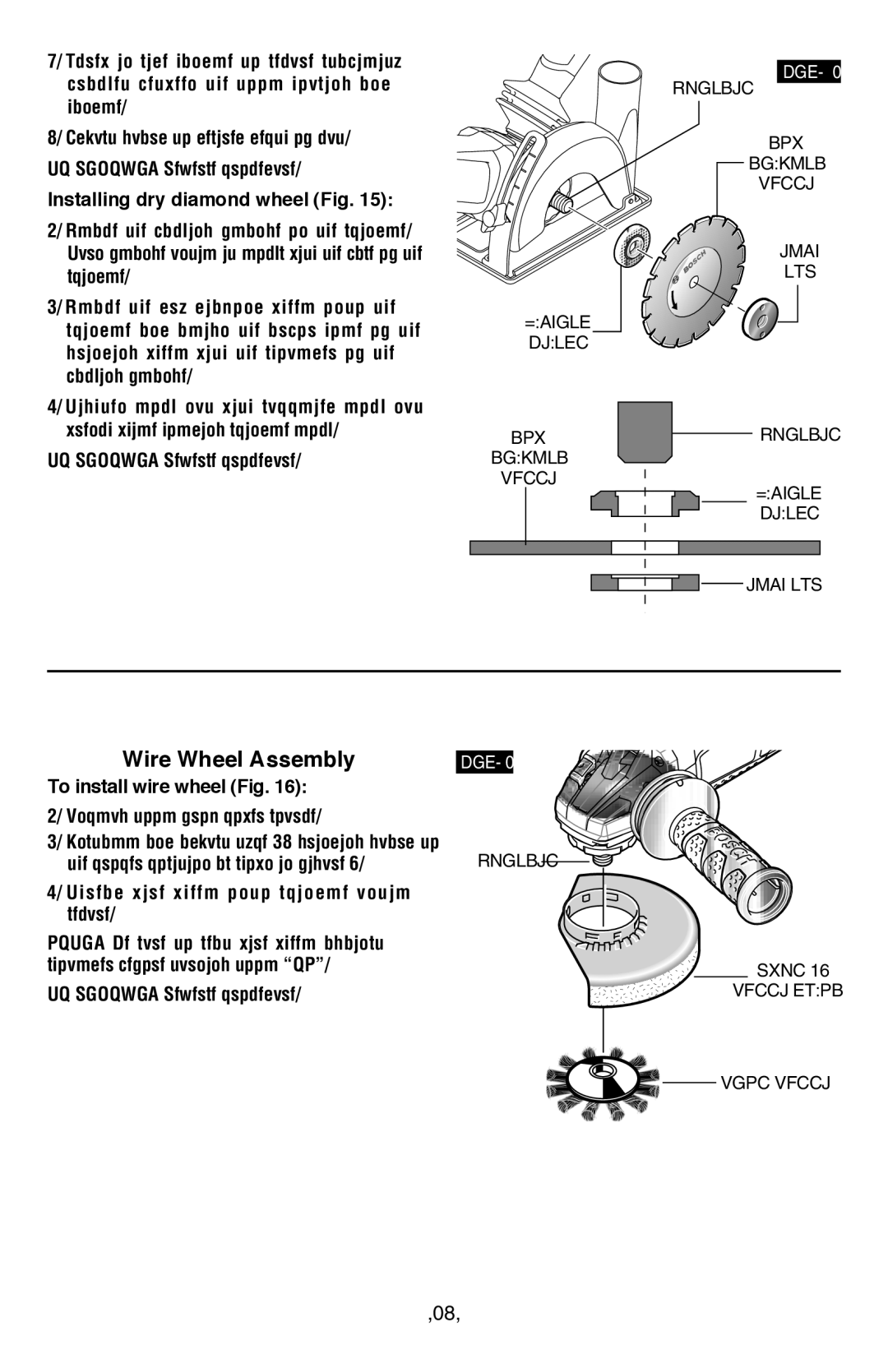

Installing dry diamond wheel (Fig. 15):

1.Place the backing flange on the spindle. Turn flange until it locks with the base of the spindle.

2.Place the dry diamond wheel onto the spindle and align the arbor hole of the grinding wheel with the shoulder of the backing flange.

3.Tighten lock nut with supplied lock nut wrench while holding spindle lock.

TO REMOVE: Reverse procedure.

BACKING

FLANGE

DRY

DIAMOND

WHEEL

FIG. 15

SPINDLE

DRY

DIAMOND

WHEEL

LOCK

NUT

SPINDLE

BACKING

FLANGE

![]()

![]()

![]()

![]() LOCK NUT

LOCK NUT

Wire Wheel Assembly

To install wire wheel (Fig. 16):

1.Unplug tool from power source.

2.Install and adjust type 27 grinding guard to the proper position as shown in figure 5.

3.Thread wire wheel onto spindle until secure.

NOTE: Be sure to seat wire wheel against shoulder before turning tool “ON”.

TO REMOVE: Reverse procedure.

FIG. 16

SPINDLE

TYPE 27

WHEEL GUARD

![]()

![]()

![]()

![]()

![]()

![]() WIRE WHEEL

WIRE WHEEL