Metal Grinding

Grinding wheels should be carefully selected in order to use the grinder most efficiently. Wheels vary in type of abrasive, bond, hardness, grit size and structure. The correct wheel to use is determined by the job. Use disc grinding wheels for fast grinding of structural steel, heavy weld beads, steel casting, stainless steel and other ferrous metals.

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.Apply minimum pressure to the work surface, allowing the tool to operate at high speed. Grinding rate is greatest when the tool operates at high speed.

3.Maintain a 10° to 15° angle between the tool and work surface, (Fig. 19).

Metal Cutting

A Type 1 wheel guard may not be included with this tool but is required when using a cutting

wheel. Cutting with a type 27 wheel guard may not provide the operator sufficient protection in the event of a wheel burst.

With this grinder it is possible to perform cutting of limited small stock such as metal tubes, piping or rebar. When cutting, work with moderate feed, adapted to the material being cut. When cutting profiles and square bar, it is best to start at the smallest cross section.

Always follow precautions for kickback.

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.The tool should always be used so that the sparks are directed away from user.

3.Apply minimum pressure to the work surface, allowing the tool to operate at high speed. Cutting rate is greatest when the tool operates at high speed.

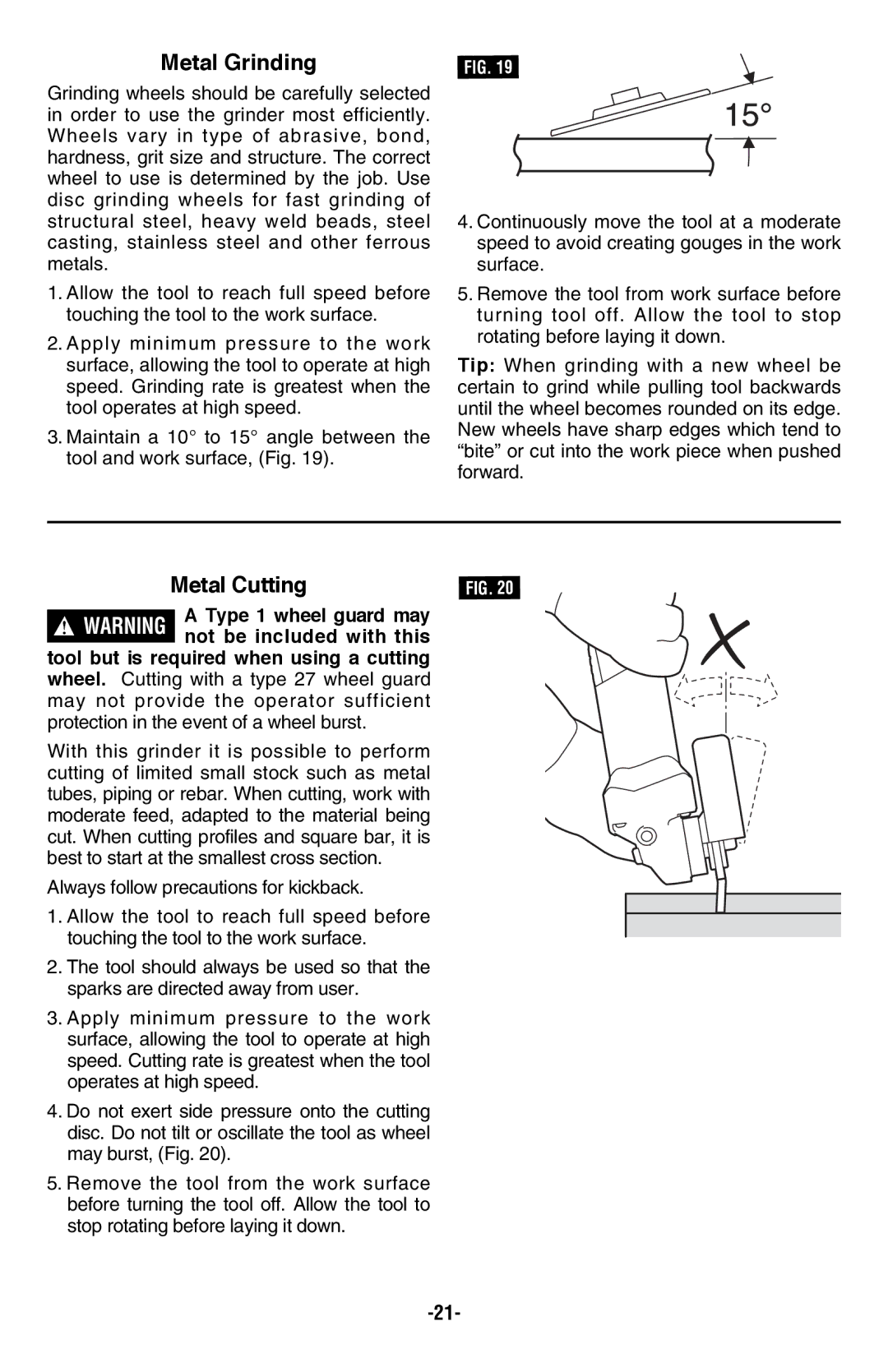

4.Do not exert side pressure onto the cutting disc. Do not tilt or oscillate the tool as wheel may burst, (Fig. 20).

5.Remove the tool from the work surface before turning the tool off. Allow the tool to stop rotating before laying it down.

FIG. 19

4.Continuously move the tool at a moderate speed to avoid creating gouges in the work surface.

5.Remove the tool from work surface before turning tool off. Allow the tool to stop rotating before laying it down.

Tip: When grinding with a new wheel be certain to grind while pulling tool backwards until the wheel becomes rounded on its edge. New wheels have sharp edges which tend to “bite” or cut into the work piece when pushed forward.

FIG. 20