Abrasive Type 27 Grinding Wheel &

Sanding Flap Disk Assembly

Your tool is equipped with a threaded spindle for mounting

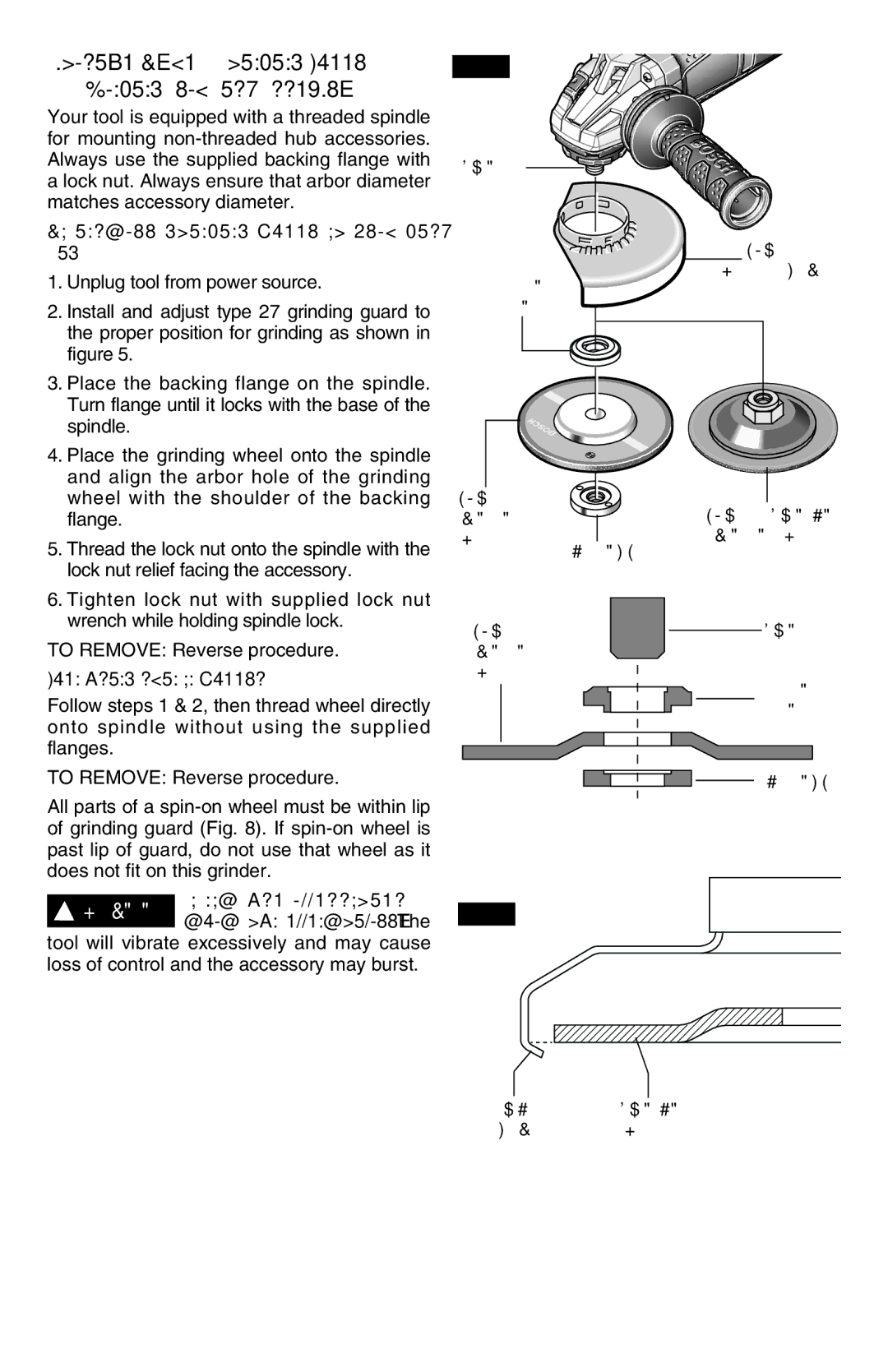

To install grinding wheel or flap disk (Fig. 7):

1.Unplug tool from power source.

2.Install and adjust type 27 grinding guard to the proper position for grinding as shown in figure 5.

3.Place the backing flange on the spindle. Turn flange until it locks with the base of the spindle.

4.Place the grinding wheel onto the spindle and align the arbor hole of the grinding wheel with the shoulder of the backing flange.

5.Thread the lock nut onto the spindle with the lock nut relief facing the accessory.

6.Tighten lock nut with supplied lock nut wrench while holding spindle lock.

TO REMOVE: Reverse procedure.

When using spin-on wheels:

Follow steps 1 & 2, then thread wheel directly onto spindle without using the supplied flanges.

TO REMOVE: Reverse procedure.

All parts of a

Do not use accessories ! WARNING that run eccentrically. The

tool will vibrate excessively and may cause loss of control and the accessory may burst.

FIG. 7

SPINDLE

TYPE 27

WHEEL GUARD

BACKING

FLANGE

TYPE 27 | TYPE 27 |

GRINDING | |

WHEEL | GRINDING WHEEL |

| LOCK NUT |

TYPE 27 | SPINDLE |

GRINDING |

|

WHEEL | BACKING |

| |

| FLANGE |

| LOCK NUT |

FIG. 8

LIP OF | |

GUARD | WHEEL |