Functional Descriptions

Electronic Clutch:

The electronics in the power tool detects situations where the wheel or accessory may be at risk to bind. The electronics prevents further rotation of the drive spindle by switching the power tool off (it does not prevent kickback). To resume operation, turn on/off switch to the off position, then restart tool.

Constant Response Circuitry:

Helps maintain near constant RPMs between

Soft Start:

Helps reduce stress on the motor that occurs from a high torque start. Helps bring accessory smoothly up to speed.

Automatic Restart Protection:

Helps prevent accidental startups after power has been interrupted, e.g. the tool was

unplugged with the switch locked in the on position. To resume operation, turn on/off switch to the off position, then restart the tool.

Overload Protection:

Helps protect tool from excessive heat that may damage motor. If tool stops or slows during operation, allow motor to cool for 30 seconds by running

Variable Speed:

Allows the grinders RPM to be adjusted for greater versatility to match needs of specific applications.

Assembly Instructions

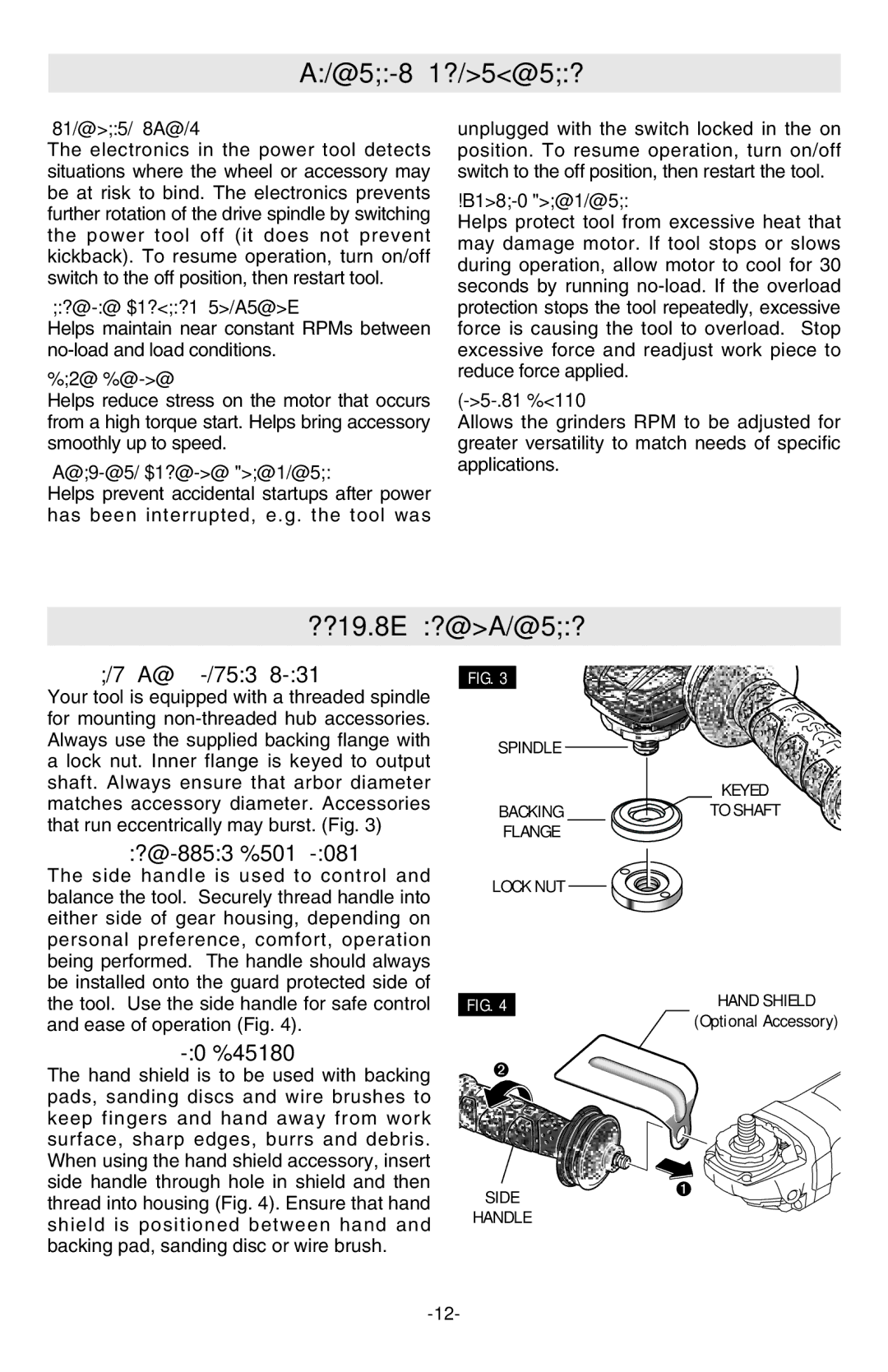

Lock Nut & Backing Flange

Your tool is equipped with a threaded spindle for mounting

Installing Side Handle

The side handle is used to control and balance the tool. Securely thread handle into either side of gear housing, depending on personal preference, comfort, operation being performed. The handle should always be installed onto the guard protected side of the tool. Use the side handle for safe control and ease of operation (Fig. 4).

Hand Shield

The hand shield is to be used with backing pads, sanding discs and wire brushes to keep fingers and hand away from work surface, sharp edges, burrs and debris. When using the hand shield accessory, insert side handle through hole in shield and then thread into housing (Fig. 4). Ensure that hand shield is positioned between hand and backing pad, sanding disc or wire brush.

FIG. 3

SPINDLE

KEYED

BACKING ![]() TO SHAFT FLANGE

TO SHAFT FLANGE

LOCK NUT ![]()

![]()

FIG. 4 | HAND SHIELD |

| (Optional Accessory) |

SIDE

HANDLE