BM 2609140437 05-06 5/23/06 3:15 PM Page 10

Operating Instructions

Bosch routers are designed for speed, accuracy and convenience in performing cabinet work, fluting, beading,

SETTING THE DEPTH OF CUT

Adjust the

1.Install desired router bit.

2.Place the router on the workpiece.

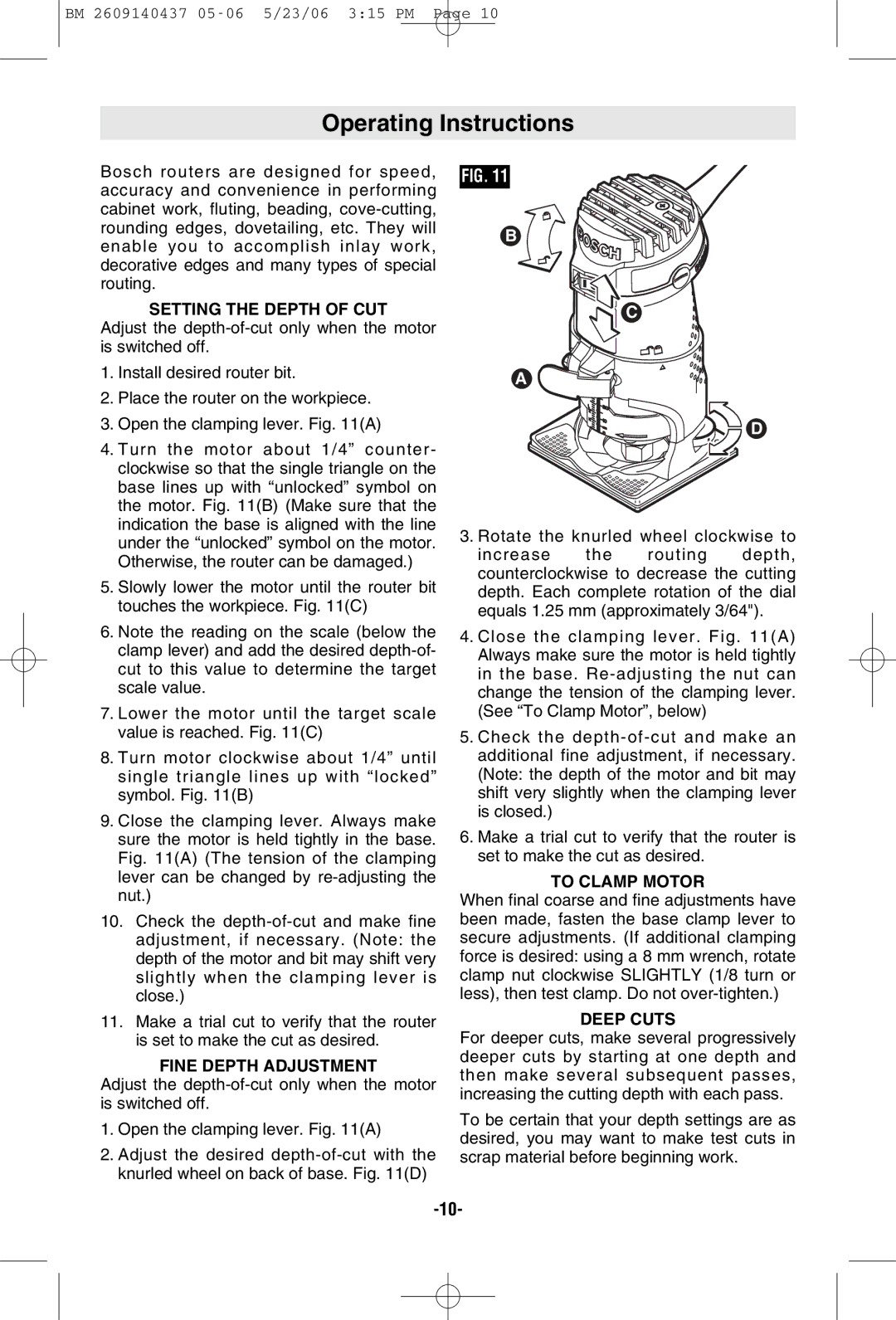

3.Open the clamping lever. Fig. 11(A)

4.Turn the motor about 1/4” counter- clockwise so that the single triangle on the base lines up with “unlocked” symbol on the motor. Fig. 11(B) (Make sure that the indication the base is aligned with the line under the “unlocked” symbol on the motor. Otherwise, the router can be damaged.)

5.Slowly lower the motor until the router bit touches the workpiece. Fig. 11(C)

6.Note the reading on the scale (below the clamp lever) and add the desired

7.Lower the motor until the target scale value is reached. Fig. 11(C)

8.Turn motor clockwise about 1/4” until single triangle lines up with “locked” symbol. Fig. 11(B)

9.Close the clamping lever. Always make sure the motor is held tightly in the base. Fig. 11(A) (The tension of the clamping lever can be changed by

10.Check the

11.Make a trial cut to verify that the router is set to make the cut as desired.

FINE DEPTH ADJUSTMENT

Adjust the

1.Open the clamping lever. Fig. 11(A)

2.Adjust the desired

FIG. 11

B

![]()

![]()

![]() C

C

A

![]()

![]()

![]()

![]() D

D

3.Rotate the knurled wheel clockwise to

increase the routing depth, counterclockwise to decrease the cutting depth. Each complete rotation of the dial equals 1.25 mm (approximately 3/64").

4.Close the clamping lever. Fig. 11(A) Always make sure the motor is held tightly in the base.

5.Check the

6.Make a trial cut to verify that the router is set to make the cut as desired.

TO CLAMP MOTOR

When final coarse and fine adjustments have been made, fasten the base clamp lever to secure adjustments. (If additional clamping force is desired: using a 8 mm wrench, rotate clamp nut clockwise SLIGHTLY (1/8 turn or less), then test clamp. Do not

DEEP CUTS

For deeper cuts, make several progressively deeper cuts by starting at one depth and then make several subsequent passes, increasing the cutting depth with each pass.

To be certain that your depth settings are as desired, you may want to make test cuts in scrap material before beginning work.