BM 2609140437 05-06 5/23/06 3:15 PM Page 11

ROCKER “ON/OFF” SWITCH

Your tool can be turned “ON” or “OFF” by the rocker switch located on the motor housing. One side of the switch is marked “I” for “ON“, and the other side of switch is marked “O” for “OFF“.

TO TURN THE TOOL “ON”: Push the side of the switch marked “I”.

TO TURN THE TOOL “OFF”: Push the side of the switch marked “O”.

SOFT START FEATURE

Electronic feedback control minimizes torque twist customary in routers by limiting the speed at which motor starts.

ELECTRONIC VARIABLE SPEED

CONTROL

(Model PR20EVS Only)

The electronic speed control feature allows motor speed to be matched to cutter size and material hardness for improved finish, extended bit life, and higher performance. Speed changes are achieved by rotating Control Dial RIGHT to increase speed, LEFT to decrease as indicated on housing (Fig. 1). Speed may be changed while tool is on. The reference numbers on the dial facilitate re- setting control to desired speed.

The speed chart indicates the relationship between settings and application, exact settings are determined by operator experience and preference. The bit manufacturer may also have a speed recommendation.

DIAL

SETTING RPM APPLICATION

1 | 16000 |

| ||

2 | 18000 |

| ||

} and cutters. | ||||

3 | 20000 | |||

4 | 22500 | } | Softwoods, plastics, | |

5 | 26500 | laminates, smaller | ||

diameter bits and | ||||

6 | 35000 | |||

cutters | ||||

|

|

| ||

CONSTANT RESPONSE™ CIRCUITRY The router's Constant Response™ Circuitry monitors and adjusts power to maintain the desired RPM for consistent performance and control.

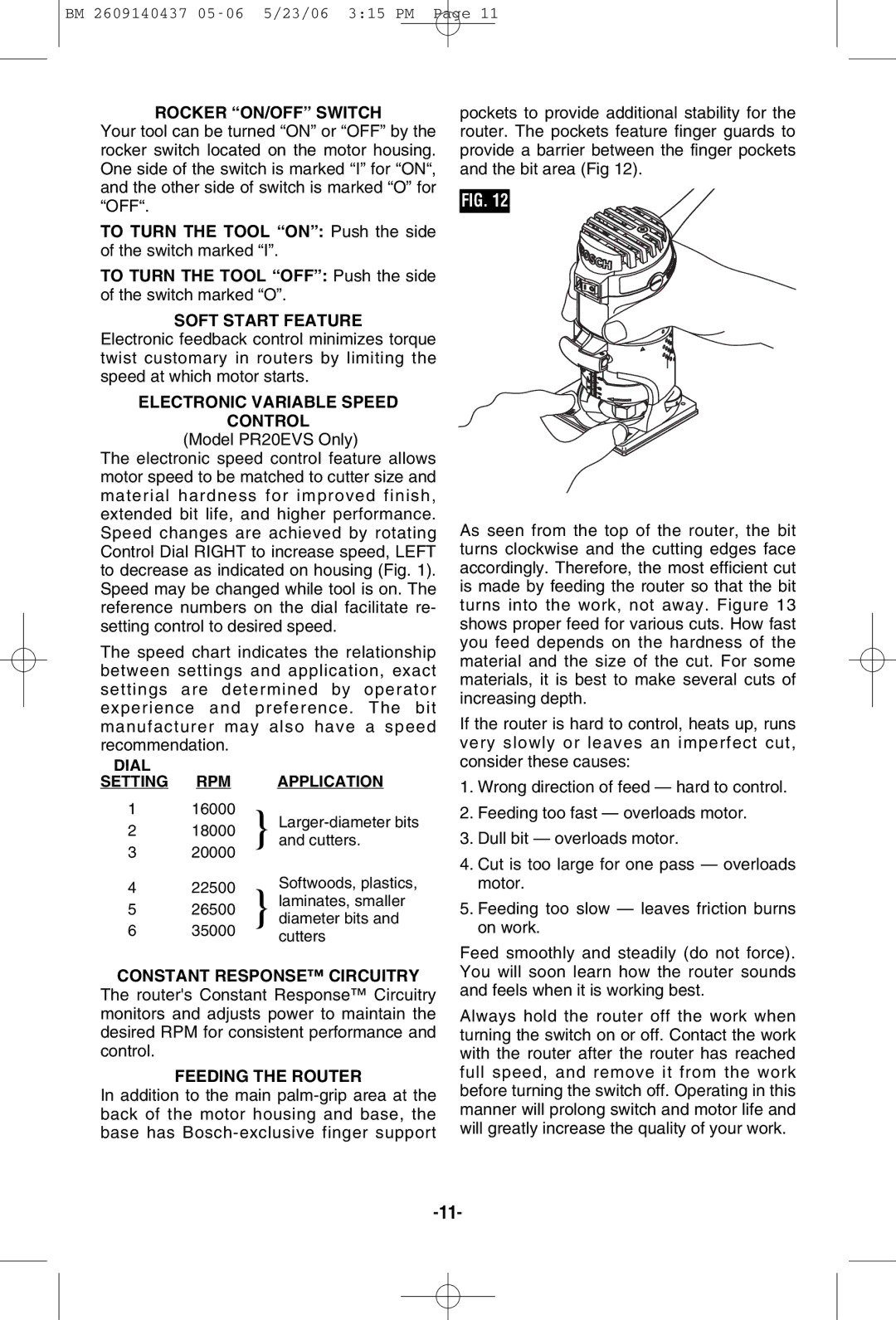

FEEDING THE ROUTER

In addition to the main

pockets to provide additional stability for the router. The pockets feature finger guards to provide a barrier between the finger pockets and the bit area (Fig 12).

FIG. 12

As seen from the top of the router, the bit turns clockwise and the cutting edges face accordingly. Therefore, the most efficient cut is made by feeding the router so that the bit turns into the work, not away. Figure 13 shows proper feed for various cuts. How fast you feed depends on the hardness of the material and the size of the cut. For some materials, it is best to make several cuts of increasing depth.

If the router is hard to control, heats up, runs very slowly or leaves an imperfect cut, consider these causes:

1.Wrong direction of feed — hard to control.

2.Feeding too fast — overloads motor.

3.Dull bit — overloads motor.

4.Cut is too large for one pass — overloads motor.

5.Feeding too slow — leaves friction burns on work.

Feed smoothly and steadily (do not force). You will soon learn how the router sounds and feels when it is working best.

Always hold the router off the work when turning the switch on or off. Contact the work with the router after the router has reached full speed, and remove it from the work before turning the switch off. Operating in this manner will prolong switch and motor life and will greatly increase the quality of your work.