BM 2610958959

Operating Tips

You will extend the life of your bits and do neater work if you always put the bit in contact with the work before pulling the trigger. During the operation, hold the tool firmly and exert light, steady pressure. Too much pressure at low speed will stall the tool. Too little pressure will keep the bit from cutting and cause excess friction by sliding over the surface. This can be damaging to both tool and bit.

DRILLING WITH VARIABLE SPEED

The trigger controlled variable speed feature will eliminate the need for center punches in hard materials. The variable speed trigger allows you to slowly increase RPM. By using a slow starting speed, you are able to keep

the bit from “wandering”. You can increase the speed as the bit “bites” into the work by squeezing the trigger.

DRIVING WITH VARIABLE SPEED

Variable speed drills will double as a power screwdriver by using a screwdriver bit in the drill mode. The technique is to start slowly, increasing the speed as the screw runs down. Set the screw snugly by slowing to a stop. Prior to driving screws, pilot and clearance holes should be drilled.

TOOL HANGER

!WARNING To avoid personal injury, do not use tool hanger as

a tether. Hanger is meant to be used for storage.

FASTENING WITH SCREWS

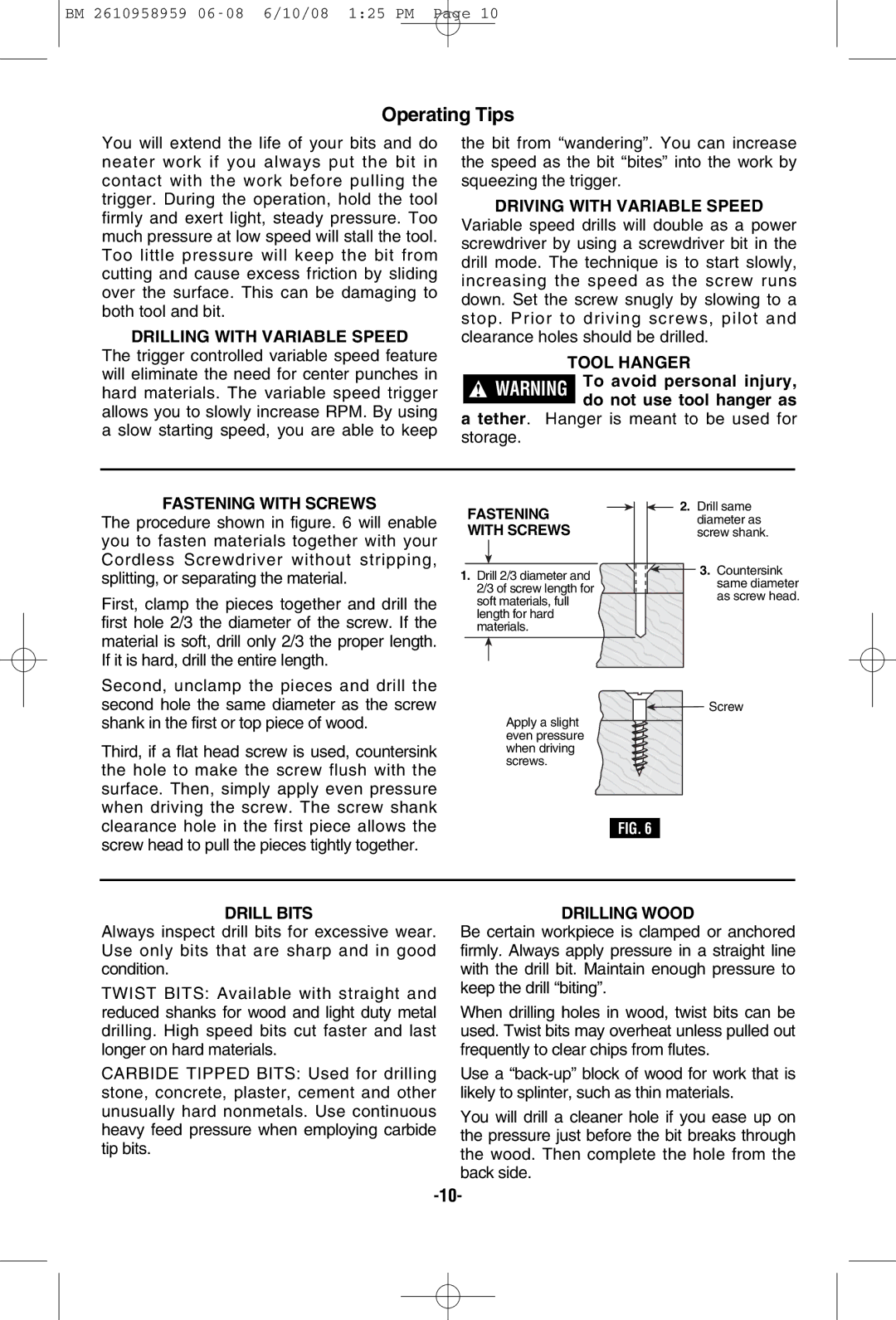

The procedure shown in figure. 6 will enable you to fasten materials together with your Cordless Screwdriver without stripping, splitting, or separating the material.

First, clamp the pieces together and drill the first hole 2/3 the diameter of the screw. If the material is soft, drill only 2/3 the proper length. If it is hard, drill the entire length.

FASTENING WITH SCREWS

1.Drill 2/3 diameter and 2/3 of screw length for soft materials, full length for hard materials.

![]() 2. Drill same diameter as screw shank.

2. Drill same diameter as screw shank.

![]() 3. Countersink same diameter as screw head.

3. Countersink same diameter as screw head.

Second, unclamp the pieces and drill the second hole the same diameter as the screw shank in the first or top piece of wood.

Third, if a flat head screw is used, countersink the hole to make the screw flush with the surface. Then, simply apply even pressure when driving the screw. The screw shank clearance hole in the first piece allows the screw head to pull the pieces tightly together.

![]() Screw

Screw

Apply a slight even pressure when driving screws.

FIG. 6

DRILL BITS

Always inspect drill bits for excessive wear. Use only bits that are sharp and in good condition.

TWIST BITS: Available with straight and reduced shanks for wood and light duty metal drilling. High speed bits cut faster and last longer on hard materials.

CARBIDE TIPPED BITS: Used for drilling stone, concrete, plaster, cement and other unusually hard nonmetals. Use continuous heavy feed pressure when employing carbide tip bits.

DRILLING WOOD

Be certain workpiece is clamped or anchored firmly. Always apply pressure in a straight line with the drill bit. Maintain enough pressure to keep the drill “biting”.

When drilling holes in wood, twist bits can be used. Twist bits may overheat unless pulled out frequently to clear chips from flutes.

Use a

You will drill a cleaner hole if you ease up on the pressure just before the bit breaks through the wood. Then complete the hole from the back side.