General |

| MAINTENANCE | |

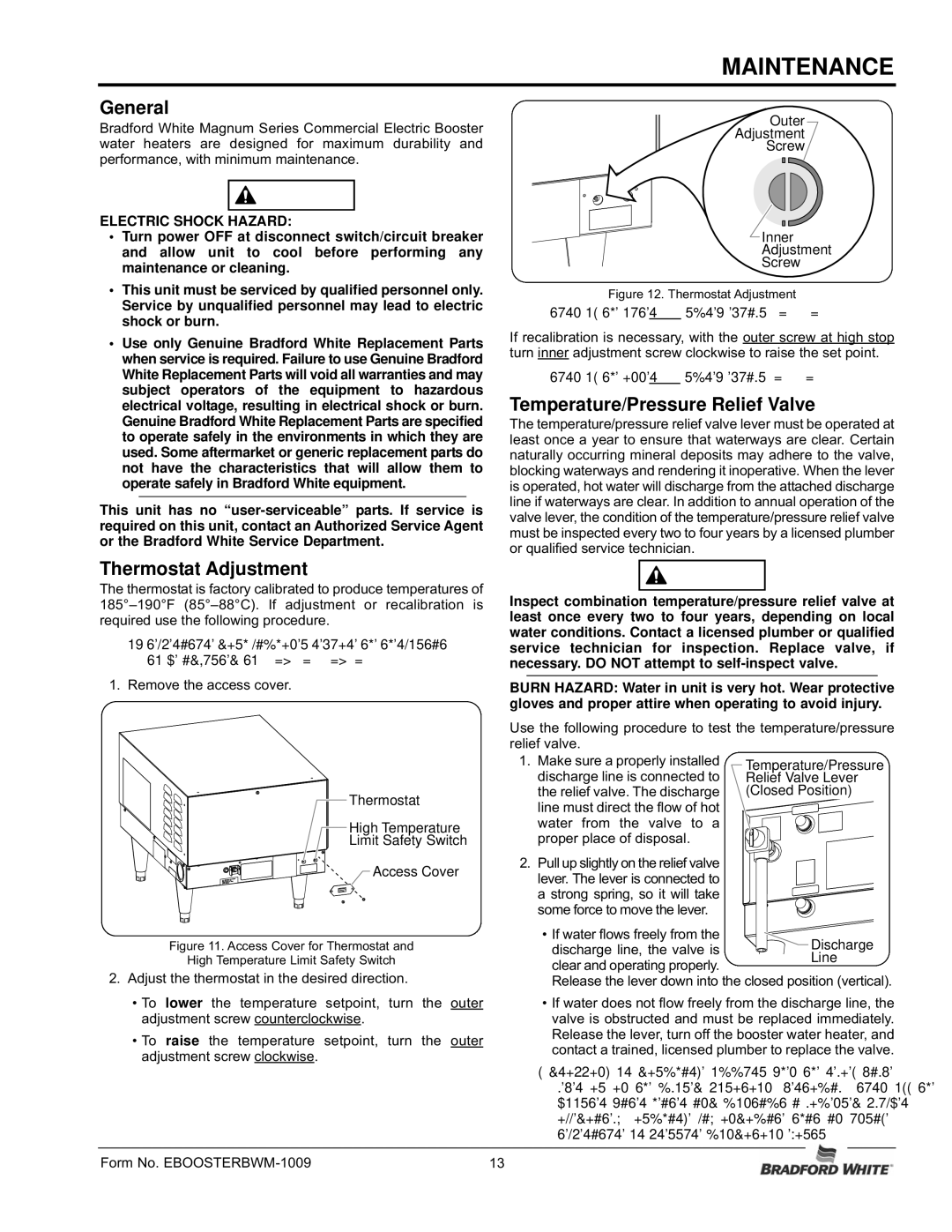

| Outer | ||

Bradford White Magnum Series Commercial Electric Booster |

| Adjustment | |

water heaters are designed for maximum durability and |

| Screw | |

performance, with minimum maintenance. |

|

| |

WARNING |

|

| |

ELECTRIC SHOCK HAZARD: |

|

| |

• Turn power OFF at disconnect switch/circuit breaker |

| Inner | |

and allow unit to cool before performing any |

| Adjustment | |

maintenance or cleaning. |

| Screw | |

• This unit must be serviced by qualified personnel only. | Figure 12. Thermostat Adjustment | ||

Service by unqualified personnel may lead to electric | NOTE: 1/6 turn of the outer screw equals 12°F (6.7°C). | ||

shock or burn. | |||

• Use only Genuine Bradford White Replacement Parts | If recalibration is necessary, with the outer screw at high stop | ||

when service is required. Failure to use Genuine Bradford | turn inner adjustment screw clockwise to raise the set point. | ||

White Replacement Parts will void all warranties and may | NOTE: 1/6 turn of the inner screw equals 8°F (4.4°C). | ||

subject operators of the equipment to hazardous | Temperature/Pressure Relief Valve | ||

electrical voltage, resulting in electrical shock or burn. | |||

Genuine Bradford White Replacement Parts are specified | The temperature/pressure relief valve lever must be operated at | ||

to operate safely in the environments in which they are | least once a year to ensure that waterways are clear. Certain | ||

used. Some aftermarket or generic replacement parts do | naturally occurring mineral deposits may adhere to the valve, | ||

not have the characteristics that will allow them to | blocking waterways and rendering it inoperative. When the lever | ||

operate safely in Bradford White equipment. | is operated, hot water will discharge from the attached discharge | ||

This unit has no | line if waterways are clear. In addition to annual operation of the | ||

valve lever, the condition of the temperature/pressure relief valve | |||

required on this unit, contact an Authorized Service Agent | must be inspected every two to four years by a licensed plumber | ||

or the Bradford White Service Department. | or qualified service technician. |

| |

Thermostat Adjustment | WARNING | ||

The thermostat is factory calibrated to produce temperatures of | |||

Inspect combination temperature/pressure relief valve at | |||

required use the following procedure. | least once every two to four years, depending on local | ||

NOTE: Low temperature dish machines require the thermostat | water conditions. Contact a licensed plumber or qualified | ||

service technician for inspection. Replace valve, if | |||

to be adjusted to | necessary. DO NOT attempt to | ||

1. Remove the access cover. | BURN HAZARD: Water in unit is very hot. Wear protective | ||

| gloves and proper attire when operating to avoid injury. | ||

| Use the following procedure to test the temperature/pressure | ||

| relief valve. |

| |

| 1. Make sure a properly installed | Temperature/Pressure | |

| discharge line is connected to | Relief Valve Lever | |

| the relief valve. The discharge | (Closed Position) | |

Thermostat | line must direct the flow of hot |

| |

High Temperature | water from the valve to a |

| |

Limit Safety Switch | proper place of disposal. |

| |

| 2. Pull up slightly on the relief valve |

| |

Access Cover | lever. The lever is connected to |

| |

| a strong spring, so it will take |

| |

| some force to move the lever. |

| |

Figure 11. Access Cover for Thermostat and | • If water flows freely from the | Discharge | |

discharge line, the valve is | |||

Line | |||

High Temperature Limit Safety Switch | clear and operating properly. |

| |

2. Adjust the thermostat in the desired direction. | Release the lever down into the closed position (vertical). | ||

• To lower the temperature setpoint, turn the outer | • If water does not flow freely from the discharge line, the | ||

adjustment screw counterclockwise. | valve is obstructed and must be replaced immediately. | ||

• To raise the temperature setpoint, turn the outer | Release the lever, turn off the booster water heater, and | ||

contact a trained, licensed plumber to replace the valve. | |||

adjustment screw clockwise. | NOTE: If dripping or discharge occurs when the relief valve | ||

| lever is in the closed position (vertical), turn off the | ||

| booster water heater and contact a licensed plumber | ||

| immediately. Discharge may indicate that an unsafe | ||

Form No. | temperature or pressure condition exists. | ||

13 |

| ||