TGHE-160E-N(X), TGHE-199E-N(X) specifications

Bradford-White Corporation is renowned for its commitment to quality and innovation in the water heating industry. Among its extensive range of products, the TGHE-199E-N(X) and TGHE-160E-N(X) models stand out for their advanced technology and reliable performance, making them a preferred choice for both residential and commercial applications.The TGHE-199E-N(X) and TGHE-160E-N(X) are high-efficiency, gas-fired water heaters designed to meet the rising demand for sustainable energy solutions without compromising on performance. Both models feature a powerful, energy-efficient design that significantly reduces energy consumption while providing a consistent supply of hot water.

One of the main features of these models is their use of advanced technology in water heating. The units are equipped with a high-efficiency burner and an optimized heat exchanger that maximizes the transfer of energy, ensuring rapid heating and minimal standby loss. This efficiency is further enhanced by their ability to modulate gas flow, allowing the heater to adjust its operation based on actual demand, rather than running at full capacity at all times.

Safety is a priority in the design of the TGHE-199E-N(X) and TGHE-160E-N(X). Both models are equipped with an electronic ignition system, which eliminates the need for a continuous pilot light, reducing gas consumption and enhancing safety. Furthermore, they include advanced venting options, such as concentric or PVC venting, providing installation flexibility while adhering to stringent building codes.

Moreover, these water heaters are built to last, featuring a durable tank design with a powder-coated, steel construction and a patented Vitraglas® lining. This lining protects against corrosion and extends the life of the tank, ensuring long-term performance and reliability.

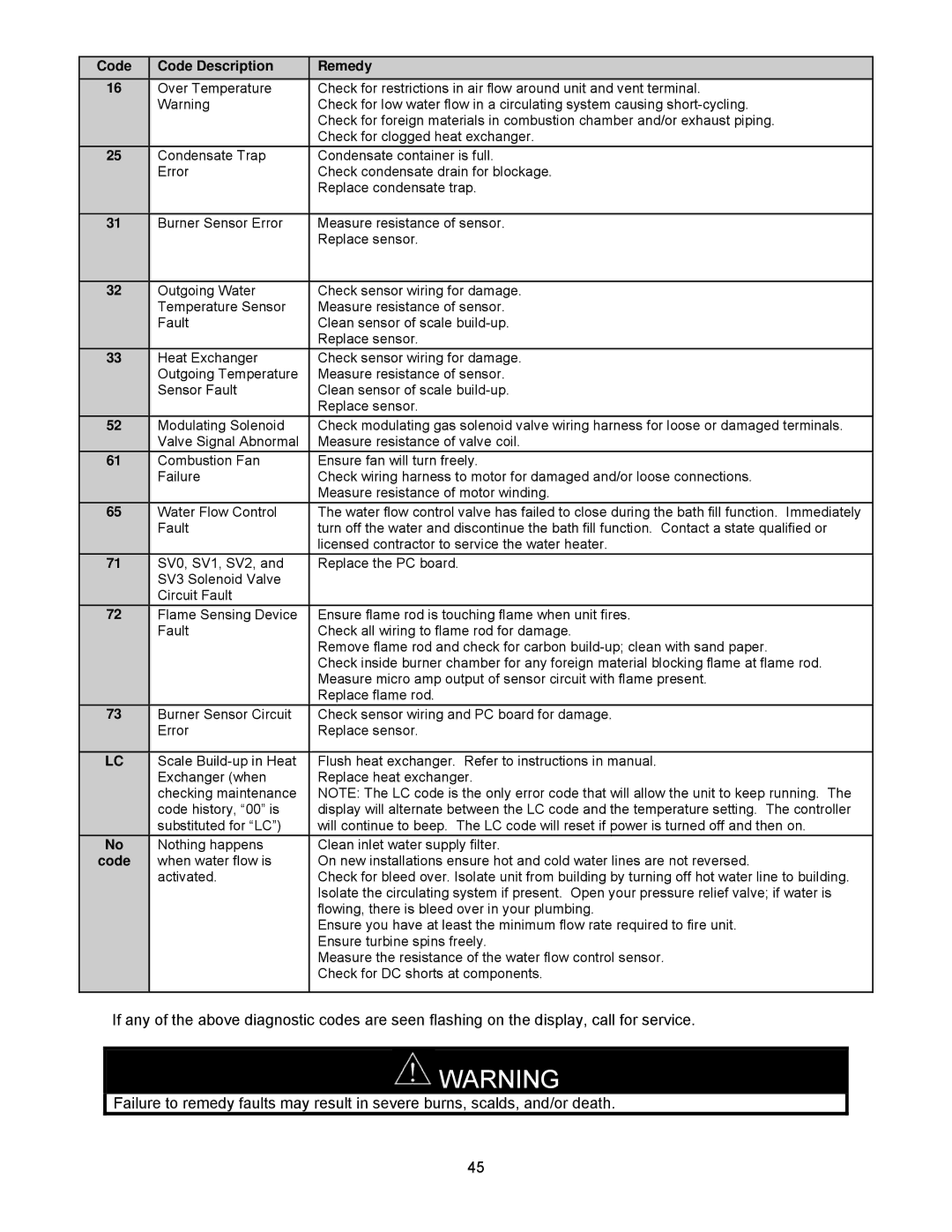

Installation and maintenance of the TGHE-199E-N(X) and TGHE-160E-N(X) are straightforward, thanks to their user-friendly design. They come with easily accessible components, making service and repairs less time-consuming and more cost-effective.

In summary, the Bradford-White TGHE-199E-N(X) and TGHE-160E-N(X) gas-fired water heaters exemplify the best in modern water heating technology. Their energy efficiency, safety features, and durable construction make them a top choice for those seeking dependable hot water solutions in residential and commercial settings. With a commitment to innovation and quality, Bradford-White continues to lead the way in delivering superior water heating products.