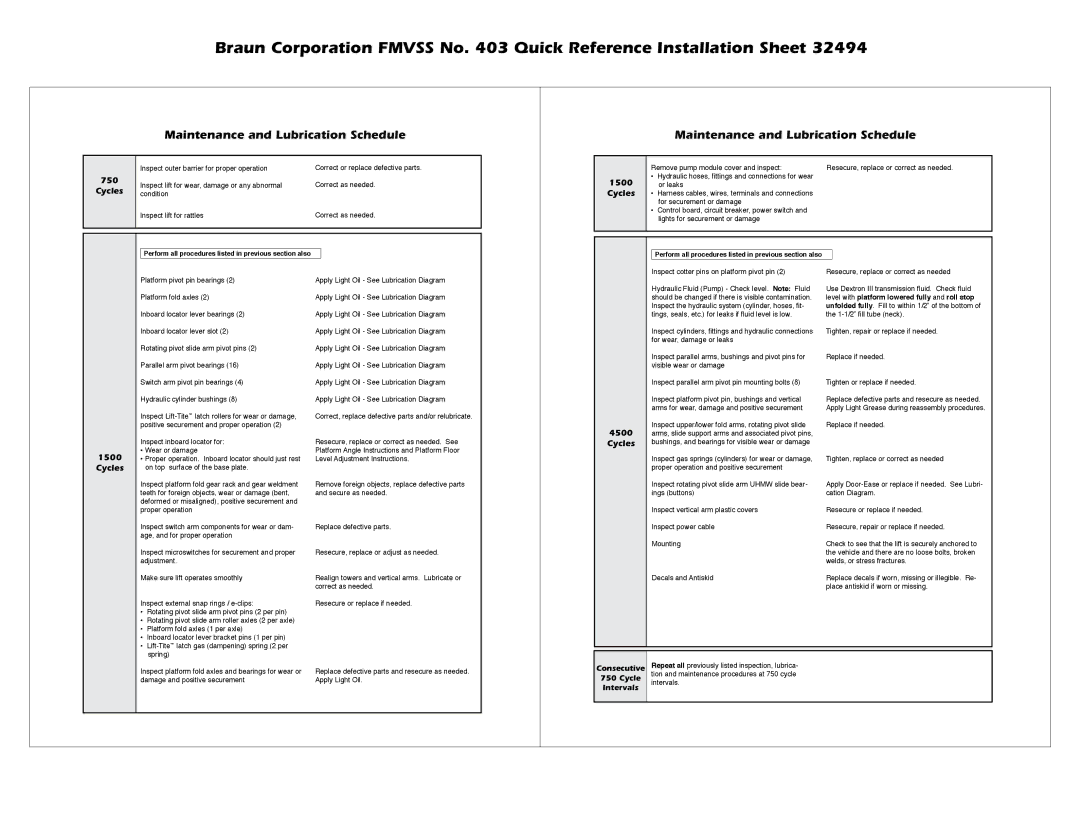

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

Maintenance and Lubrication Schedule

| Inspect outer barrier for proper operation | Correct or replace defective parts. | ||||

750 | Inspect lift for wear, damage or any abnormal | Correct as needed. | ||||

Cycles | ||||||

condition |

|

| ||||

| Inspect lift for rattles | Correct as needed. | ||||

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

| Perform all procedures listed in previous section also |

|

| |

|

| Platform pivot pin bearings (2) | Apply Light Oil - See Lubrication Diagram | |||

|

| Platform fold axles (2) | Apply Light Oil - See Lubrication Diagram | |||

|

| Inboard locator lever bearings (2) | Apply Light Oil - See Lubrication Diagram | |||

|

| Inboard locator lever slot (2) | Apply Light Oil - See Lubrication Diagram | |||

|

| Rotating pivot slide arm pivot pins (2) | Apply Light Oil - See Lubrication Diagram | |||

|

| Parallel arm pivot bearings (16) | Apply Light Oil - See Lubrication Diagram | |||

|

| Switch arm pivot pin bearings (4) | Apply Light Oil - See Lubrication Diagram | |||

|

| Hydraulic cylinder bushings (8) | Apply Light Oil - See Lubrication Diagram | |||

|

| Inspect | Correct, replace defective parts and/or relubricate. | |||

|

| positive securement and proper operation (2) |

|

| ||

|

| Inspect inboard locator for: | Resecure, replace or correct as needed. See | |||

1500 |

| • Wear or damage | Platform Angle Instructions and Platform Floor | |||

| • Proper operation. Inboard locator should just rest | Level Adjustment Instructions. | ||||

Cycles |

|

| on top surface of the base plate. |

|

| |

|

| Inspect platform fold gear rack and gear weldment | Remove foreign objects, replace defective parts | |||

|

| teeth for foreign objects, wear or damage (bent, | and secure as needed. | |||

|

| deformed or misaligned), positive securement and |

|

| ||

|

| proper operation |

|

| ||

|

| Inspect switch arm components for wear or dam- | Replace defective parts. | |||

|

| age, and for proper operation |

|

| ||

|

| Inspect microswitches for securement and proper | Resecure, replace or adjust as needed. | |||

|

| adjustment. |

|

| ||

|

| Make sure lift operates smoothly | Realign towers and vertical arms. Lubricate or | |||

|

|

|

| correct as needed. | ||

|

| Inspect external snap rings / | Resecure or replace if needed. | |||

|

| • | Rotating pivot slide arm pivot pins (2 per pin) |

|

| |

|

| • | Rotating pivot slide arm roller axles (2 per axle) |

|

| |

|

| • | Platform fold axles (1 per axle) |

|

| |

|

| • | Inboard locator lever bracket pins (1 per pin) |

|

| |

|

| • |

|

| ||

|

|

| spring) |

|

| |

|

| Inspect platform fold axles and bearings for wear or | Replace defective parts and resecure as needed. | |||

|

| damage and positive securement | Apply Light Oil. | |||

|

|

|

|

|

| |

Maintenance and Lubrication Schedule

| Remove pump module cover and inspect: | Resecure, replace or correct as needed. | |||

1500 | • | Hydraulic hoses, fittings and connections for wear |

|

| |

• | or leaks |

|

| ||

Cycles | Harness cables, wires, terminals and connections |

|

| ||

| • | for securement or damage |

|

| |

| Control board, circuit breaker, power switch and |

|

| ||

|

|

| lights for securement or damage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Perform all procedures listed in previous section also |

|

|

|

| Inspect cotter pins on platform pivot pin (2) | Resecure, replace or correct as needed | ||

|

| Hydraulic Fluid (Pump) - Check level. Note: Fluid | Use Dextron III transmission fluid. Check fluid | ||

|

| should be changed if there is visible contamination. | level with platform lowered fully and roll stop | ||

|

| Inspect the hydraulic system (cylinder, hoses, fit- | unfolded fully. Fill to within 1/2” of the bottom of | ||

|

| tings, seals, etc.) for leaks if fluid level is low. | the | ||

|

| Inspect cylinders, fittings and hydraulic connections | Tighten, repair or replace if needed. | ||

|

| for wear, damage or leaks |

|

| |

|

| Inspect parallel arms, bushings and pivot pins for | Replace if needed. | ||

|

| visible wear or damage |

|

| |

|

| Inspect parallel arm pivot pin mounting bolts (8) | Tighten or replace if needed. | ||

|

| Inspect platform pivot pin, bushings and vertical | Replace defective parts and resecure as needed. | ||

|

| arms for wear, damage and positive securement | Apply Light Grease during reassembly procedures. | ||

|

| Inspect upper/lower fold arms, rotating pivot slide | Replace if needed. | ||

4500 |

| arms, slide support arms and associated pivot pins, |

|

| |

Cycles |

| bushings, and bearings for visible wear or damage |

|

| |

|

| Inspect gas springs (cylinders) for wear or damage, | Tighten, replace or correct as needed | ||

|

| proper operation and positive securement |

|

| |

|

| Inspect rotating pivot slide arm UHMW slide bear- | Apply | ||

|

| ings (buttons) | cation Diagram. | ||

|

| Inspect vertical arm plastic covers | Resecure or replace if needed. | ||

|

| Inspect power cable | Resecure, repair or replace if needed. | ||

|

| Mounting | Check to see that the lift is securely anchored to | ||

|

|

|

| the vehicle and there are no loose bolts, broken | |

|

|

|

| welds, or stress fractures. | |

|

| Decals and Antiskid | Replace decals if worn, missing or illegible. Re- | ||

|

|

|

| place antiskid if worn or missing. | |

|

|

|

|

|

|

Consecutive | Repeat all previously listed inspection, lubrica- | |

750 Cycle | tion and maintenance procedures at 750 cycle | |

intervals. | ||

Intervals | ||

| ||

|

|