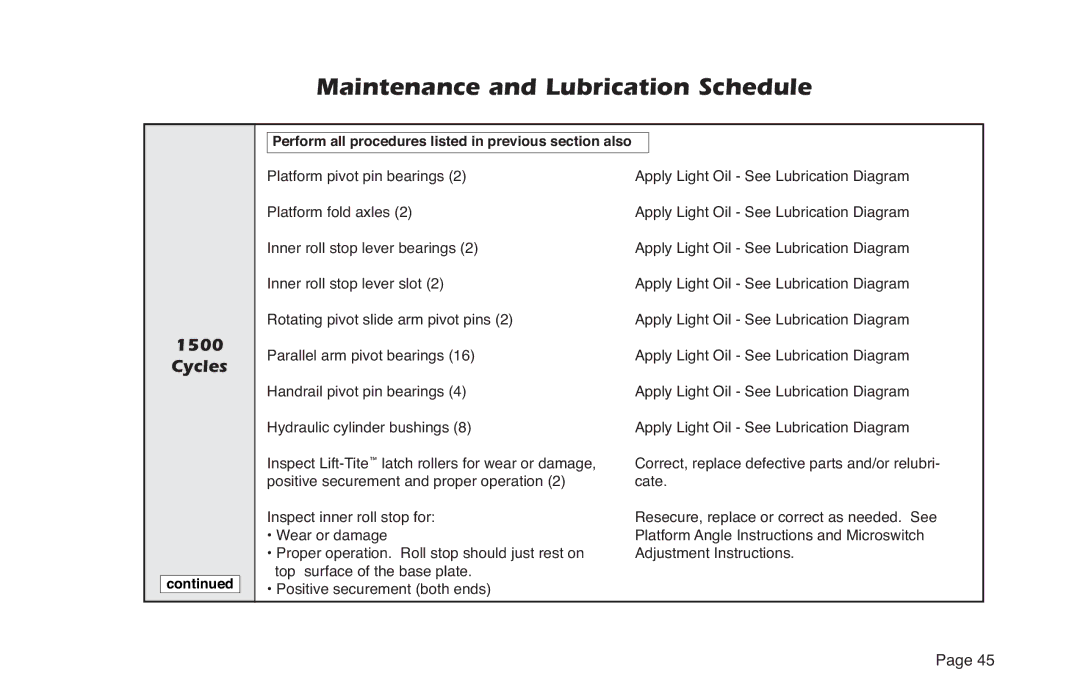

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

1500

Cycles

continued

Platform pivot pin bearings (2)

Platform fold axles (2)

Inner roll stop lever bearings (2)

Inner roll stop lever slot (2)

Rotating pivot slide arm pivot pins (2)

Parallel arm pivot bearings (16)

Handrail pivot pin bearings (4)

Hydraulic cylinder bushings (8)

Inspect

Inspect inner roll stop for:

•Wear or damage

•Proper operation. Roll stop should just rest on top surface of the base plate.

•Positive securement (both ends)

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct, replace defective parts and/or relubri- cate.

Resecure, replace or correct as needed. See Platform Angle Instructions and Microswitch Adjustment Instructions.

Page 45