INSTALLATION

13

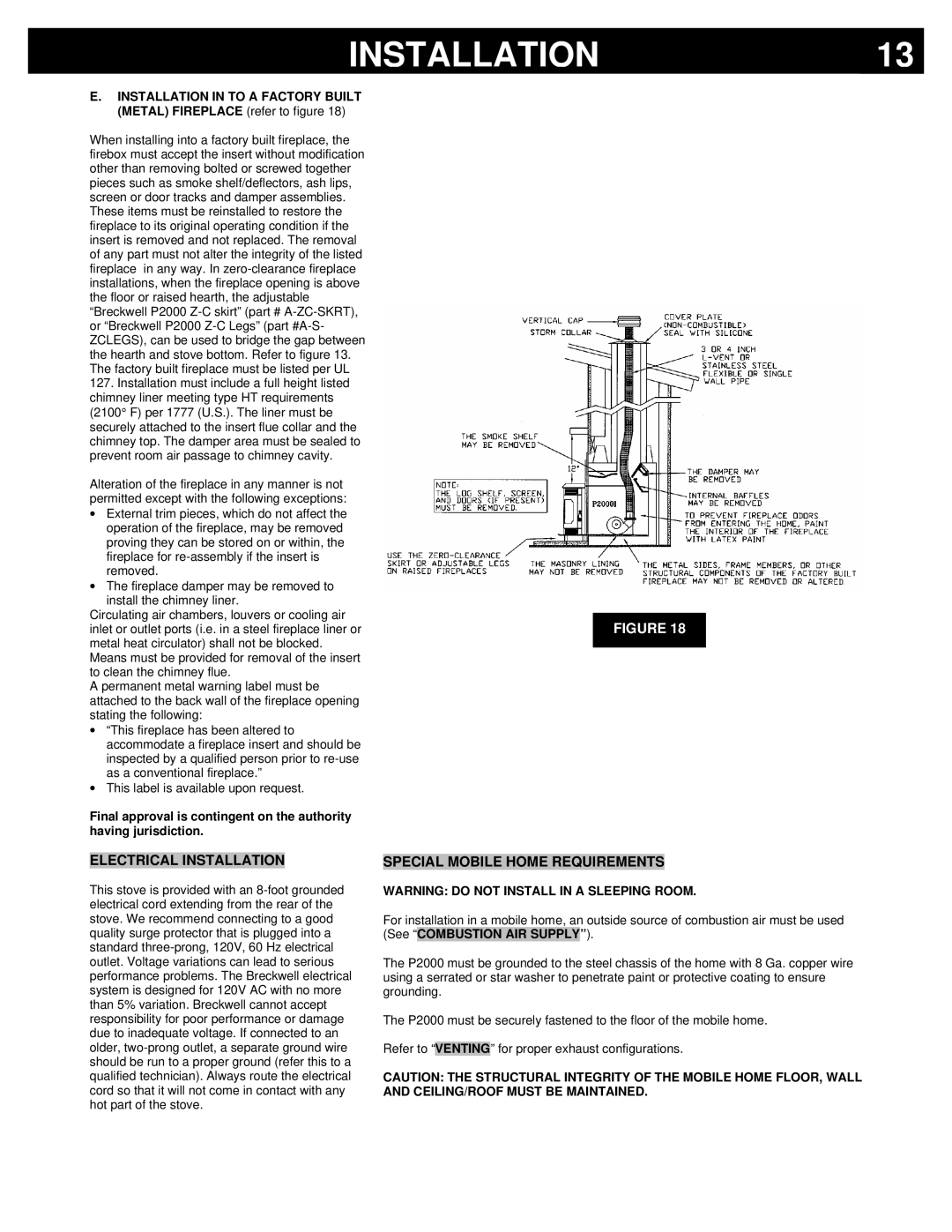

E.INSTALLATION IN TO A FACTORY BUILT (METAL) FIREPLACE (refer to figure 18)

When installing into a factory built fireplace, the firebox must accept the insert without modification other than removing bolted or screwed together pieces such as smoke shelf/deflectors, ash lips, screen or door tracks and damper assemblies. These items must be reinstalled to restore the fireplace to its original operating condition if the insert is removed and not replaced. The removal of any part must not alter the integrity of the listed fireplace in any way. In

127.Installation must include a full height listed chimney liner meeting type HT requirements (2100° F) per 1777 (U.S.). The liner must be securely attached to the insert flue collar and the chimney top. The damper area must be sealed to prevent room air passage to chimney cavity.

Alteration of the fireplace in any manner is not permitted except with the following exceptions:

∙External trim pieces, which do not affect the operation of the fireplace, may be removed proving they can be stored on or within, the fireplace for

∙The fireplace damper may be removed to install the chimney liner.

Circulating air chambers, louvers or cooling air inlet or outlet ports (i.e. in a steel fireplace liner or metal heat circulator) shall not be blocked. Means must be provided for removal of the insert to clean the chimney flue.

A permanent metal warning label must be attached to the back wall of the fireplace opening stating the following:

∙“This fireplace has been altered to accommodate a fireplace insert and should be inspected by a qualified person prior to

∙This label is available upon request.

Final approval is contingent on the authority having jurisdiction.

FIGURE 18

ELECTRICAL INSTALLATION

This stove is provided with an

SPECIAL MOBILE HOME REQUIREMENTS

WARNING: DO NOT INSTALL IN A SLEEPING ROOM.

For installation in a mobile home, an outside source of combustion air must be used (See “COMBUSTION AIR SUPPLY”).

The P2000 must be grounded to the steel chassis of the home with 8 Ga. copper wire using a serrated or star washer to penetrate paint or protective coating to ensure grounding.

The P2000 must be securely fastened to the floor of the mobile home.

Refer to “VENTING” for proper exhaust configurations.

CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME FLOOR, WALL AND CEILING/ROOF MUST BE MAINTAINED.