MAINTENANCE

21

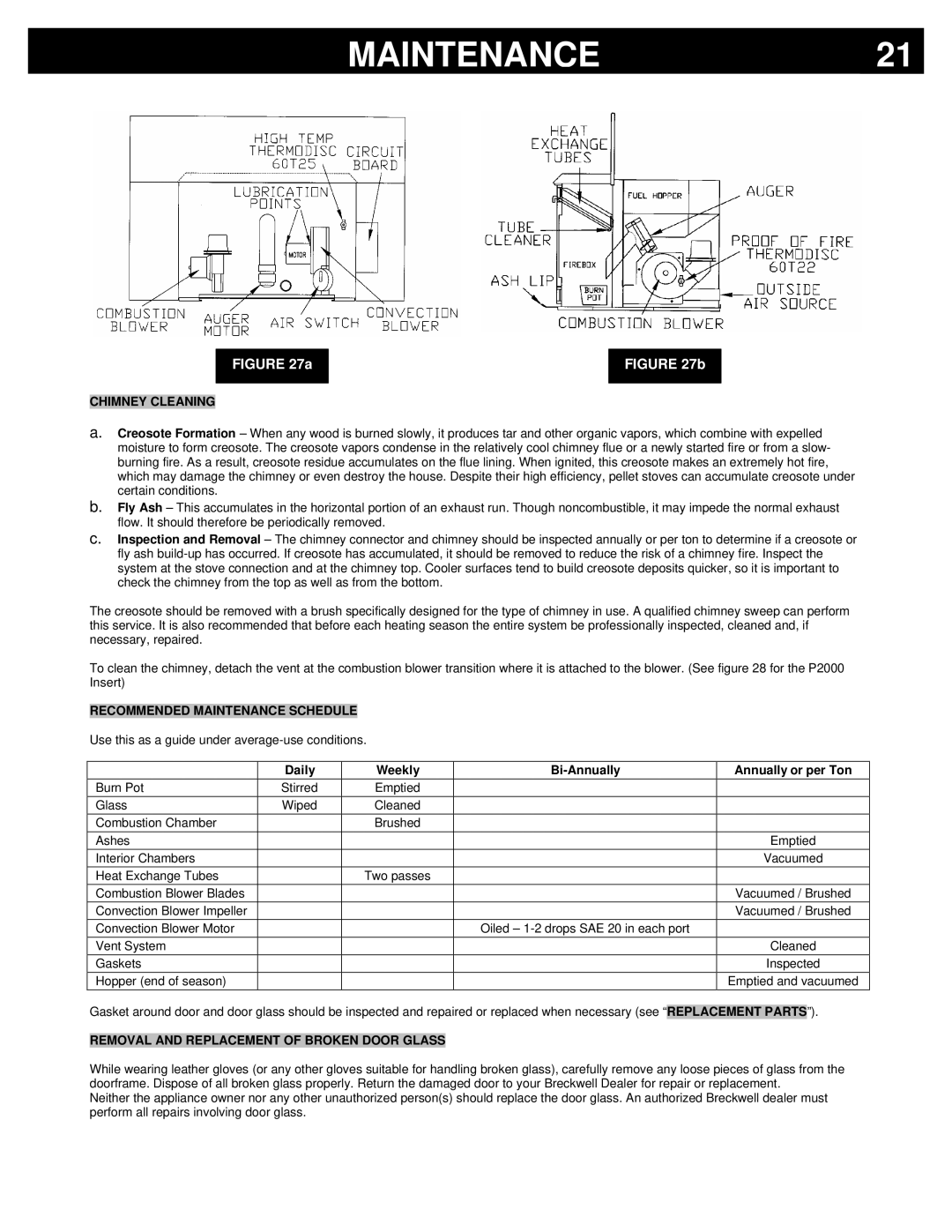

FIGURE 27a

CHIMNEY CLEANING

FIGURE 27b

a.Creosote Formation – When any wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to form creosote. The creosote vapors condense in the relatively cool chimney flue or a newly started fire or from a slow- burning fire. As a result, creosote residue accumulates on the flue lining. When ignited, this creosote makes an extremely hot fire, which may damage the chimney or even destroy the house. Despite their high efficiency, pellet stoves can accumulate creosote under certain conditions.

b.Fly Ash – This accumulates in the horizontal portion of an exhaust run. Though noncombustible, it may impede the normal exhaust flow. It should therefore be periodically removed.

c.Inspection and Removal – The chimney connector and chimney should be inspected annually or per ton to determine if a creosote or fly ash

The creosote should be removed with a brush specifically designed for the type of chimney in use. A qualified chimney sweep can perform this service. It is also recommended that before each heating season the entire system be professionally inspected, cleaned and, if necessary, repaired.

To clean the chimney, detach the vent at the combustion blower transition where it is attached to the blower. (See figure 28 for the P2000 Insert)

RECOMMENDED MAINTENANCE SCHEDULE

Use this as a guide under

| Daily | Weekly |

| Annually or per Ton |

Burn Pot | Stirred | Emptied |

|

|

Glass | Wiped | Cleaned |

|

|

Combustion Chamber |

| Brushed |

|

|

|

|

|

|

|

Ashes |

|

|

| Emptied |

|

|

|

|

|

Interior Chambers |

|

|

| Vacuumed |

|

|

|

|

|

Heat Exchange Tubes |

| Two passes |

|

|

|

|

|

|

|

Combustion Blower Blades |

|

|

| Vacuumed / Brushed |

|

|

|

|

|

Convection Blower Impeller |

|

|

| Vacuumed / Brushed |

|

|

|

|

|

Convection Blower Motor |

|

| Oiled – |

|

|

|

|

|

|

Vent System |

|

|

| Cleaned |

Gaskets |

|

|

| Inspected |

Hopper (end of season) |

|

|

| Emptied and vacuumed |

Gasket around door and door glass should be inspected and repaired or replaced when necessary (see “REPLACEMENT PARTS”).

REMOVAL AND REPLACEMENT OF BROKEN DOOR GLASS

While wearing leather gloves (or any other gloves suitable for handling broken glass), carefully remove any loose pieces of glass from the doorframe. Dispose of all broken glass properly. Return the damaged door to your Breckwell Dealer for repair or replacement.

Neither the appliance owner nor any other unauthorized person(s) should replace the door glass. An authorized Breckwell dealer must perform all repairs involving door glass.