Maintenance Instructions | LUBRICATION/CLEANING |

Use 3/8" hex wrench

to remove filter

Transaxle Oil Filter Location

3.Reinstall drain plugs.

4.Place 6” (15 cm) block under the left hand drive wheel.

5.Remove the oil reservoir hose attached to the elbow on top of the transaxles and remove the elbows to access the oil fill openings.

6.Fill the transaxles with

7.Before reinstalling the elbows, screw the locking nut on the elbows down until they are snug (the

8.Reinstall the elbows. When the elbow begins to be snug, position the elbow as it was when removed and tighten the lock nut.

9.Remove the block from the left wheel and reat- tach the reservoir hoses to the transaxles.

10.Fill both reservoirs to 1” (25 mm) with

11.Start and drive the unit for 1- 2 minutes.

12.If the transaxles sound noisy or have poor steer- ing response, recheck oil level in both transaxles by removing the elbows (check oil level at fill opening).

13.If oil needs to be added refer back to steps

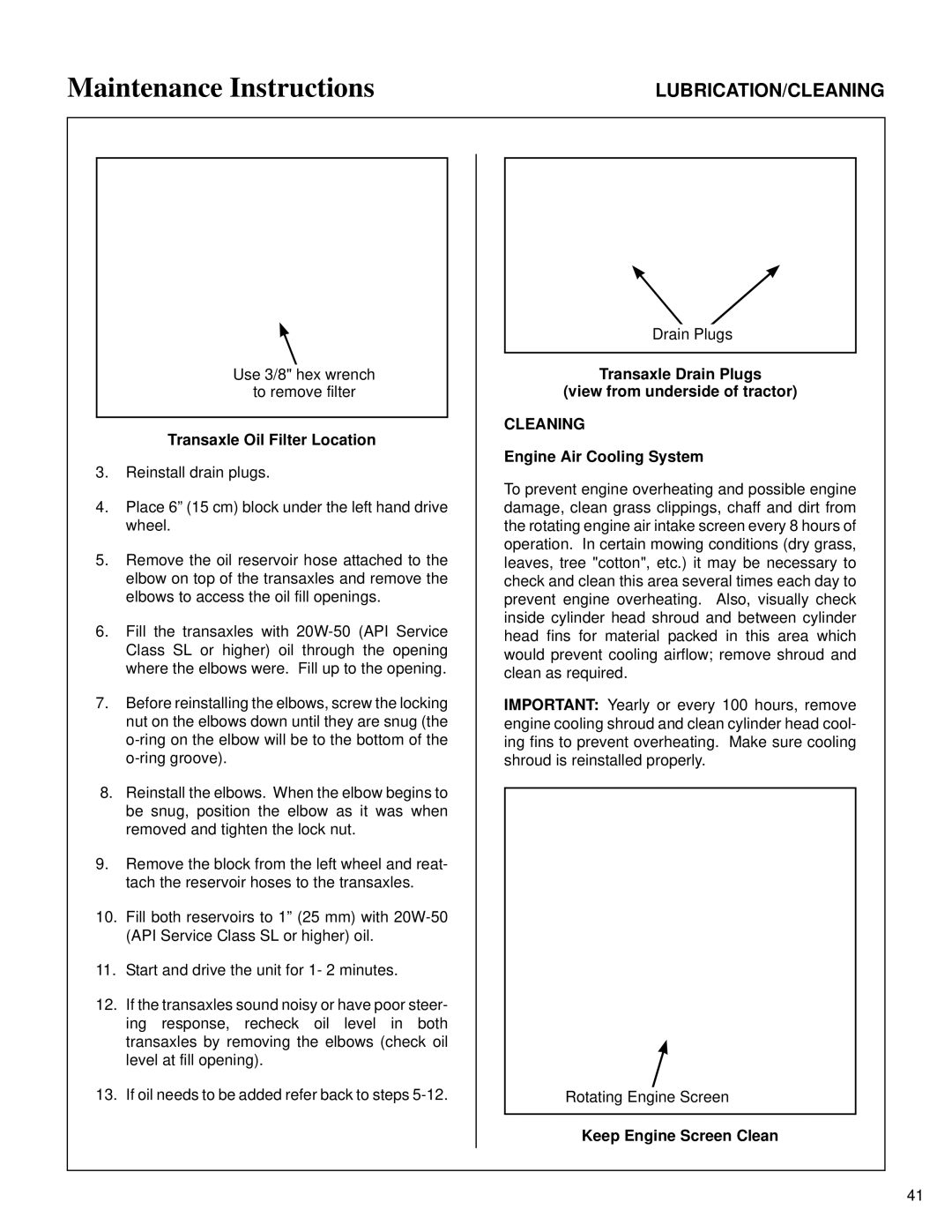

Drain Plugs

Transaxle Drain Plugs

(view from underside of tractor)

CLEANING

Engine Air Cooling System

To prevent engine overheating and possible engine damage, clean grass clippings, chaff and dirt from the rotating engine air intake screen every 8 hours of operation. In certain mowing conditions (dry grass, leaves, tree "cotton", etc.) it may be necessary to check and clean this area several times each day to prevent engine overheating. Also, visually check inside cylinder head shroud and between cylinder head fins for material packed in this area which would prevent cooling airflow; remove shroud and clean as required.

IMPORTANT: Yearly or every 100 hours, remove engine cooling shroud and clean cylinder head cool- ing fins to prevent overheating. Make sure cooling shroud is reinstalled properly.

Rotating Engine Screen

Keep Engine Screen Clean

41