PR-600

Important Safety Instructions

For Users in the UK, EIRE, Malta and Cyprus only

Page

Thank YOU for Choosing OUR Machine

License Agreement

Label locations

Concerning optional embroidery cards

Precautions

Concerning USB media

Six-needle machine embroidering

Machine Structure and Features

Viii

Differences with single-needle machines

Machine Structure and Features

Wide selection of built-in thread color information

Other features

Safety mechanism

Easy-to-read and easy-to-use LCD

Various built-in patterns

Available features

Embroidery pattern editing

Searching for information

Read when additional information is required

Manual Structure

Read before use

Contents

Xiv

Using the Settings Key

Temporary Needle Bar Setting Reserved Needle Bar Settings

Embroidery Data Precautions

Editing the Embroidery Pattern Embroidering Settings Screen

Xvi

Setup location

Accessories

Front view Right-side/rear view Operation panel

Front view

Names of Machine Parts and Their Functions

Names of Machine Parts and Their Functions

USB Type a host port connector

Right-side/rear view

Operation panel

Accessories

Included Accessories

Embroidery card

Optional Accessories

Optional Accessories

Following are available as optional accessories

Setup and transporting precautions

Setting Up the Machine

Setting Up the Machine

Setup location

Foot can be turned

Setting up the machine

Loosen 2 thumb screws to bring the operation panel forward

Adjusting the operation panel position

Preparing the thread guide assembly

Attaching the embroidery frame holder

Positioning the spool stand

Remove the two thumb screws of the embroidery frame holder

This completes the preparation of the machine

Embroidering Tutorial

Power supply precautions

Operating Precautions

Checking the needle

Needle precautions

Bobbin precautions

Operating Precautions

Fabric recommendations

Upper thread recommendations

Display recommendations

Following pages

Basic Procedures

Basic Procedures

Embroidering settings

Removing the bobbin case

Installing the Bobbin

Installing the bobbin case

Installing the bobbin

Installing the Bobbin

Buzzer beeps once and the LCD screen comes on

Turning on the Machine

Carriage moves to its initial position

Turning on the Machine

Understanding the screens

Upper threads.Touch the unlock key so

Screen overview

Basic operation flow is shown below

Selecting an Embroidery Pattern

Selecting an Embroidery Pattern

Checking a preview image from the pattern selection screen

Is displayed

Selecting an embroidery pattern

1Touch to select the embroidery patterns category

2Touch

1Press

Editing the Embroidery Pattern

Editing the Embroidery Pattern

When

Specifying Embroidering Setting

1Touch

Previewing the Image

Checking a preview image

Previewing the Image

Embroidery frame types

Hooping the Fabric in the Embroidery Frame

Hooping the fabric in the embroidery frame

Select an embroidery frame

2Loosen the screw on the outer frame

Hooping the Fabric in the Embroidery Frame

4Press the inner frame into the outer frame

Attaching the embroidery frame

Attaching the Embroidery Frame to the Machine

Inner frame should be on top Incorrect frame positioning

Attaching the Embroidery Frame to the Machine

Loosen the two thumb screws on the embroidery frame holder

For this example, align with mark

Embroidering screen appears

Checking the Embroidery Area

Continuing to the embroidering screen

Embroidery frame stops moving, and the next screen appears

Thread colors in this screen

Upper Threading

Checking the needle bars and thread colors

Upper Threading

Screen indicating that the spools be changed is closed

Touch

As indicated

Upper threading

#50 in Japan

Make sure that the spool stand is opened in the shape of a

Make sure that the thread is securely caught

4 3 2

Middle thread guide Thread guide pin

Press the automatic needle-threading button

Threading the needle

Selected needle bar moves to the embroidery position

Moving the needle bar to be threaded to the sewing position

Using the spool net

Touch to unlock the embroidery machine

Sewing the Embroidery

Starting embroidering

Locking mechanism

Following screen appears

Sewing the Embroidery

Continuing embroidering

2Press the thread trimming button

Temporarily pausing Press the start/stop button

Set the main power switch to

Stopping embroidering

Checking the Thread Tension

Checking the Thread Tension

Correct thread tension

Removing the embroidery frame

Removing the Embroidery Frame and Fabric

Removing the fabric

Turning OFF the Machine

2Unplug the power supply cord from the electrical outlet

Grasp the plug when unplugging the power supply cord

Turning OFF the Machine

Turned off either before or after embroidering Turned on

Screen Quick Reference Guide

Screen Quick Reference Guide

Key displays

Common screen controls

Understanding the pattern type selection screen

Understanding the pattern list screen

Understanding the pattern editing screen

Sewing position is moved to the center

Selects the pattern that is being edited when

Have been combined

Edited in the direction of the arrow If Is touched

Repeat sewing is selected

Understanding the embroidering settings screen

Sewing is selected

Shows the horizontal distance between patterns when

Color key Moves the sewing position of the whole pattern

Functions Rotates the entire embroidery pattern when it

Consists of multiple patterns that have been Combined

Repeatedly sews the pattern

Understanding the embroidering screen

Stitching. Use this key in the following situations

Enables the needle bar settings to manually be specified

Key Stop as the next color begins

Moves the needle forward or backward through

Needle at the embroidering position

When You Have a Question, This May Help You

USB Type a host and USB Type B function

Needle number

Thread tension changed suddenly

When You Have a Question, This May Help You

Getting false thread breakage error

Customize the embroidery colors

Embroidering Tutorial

Other Basic Procedures

If the operation in the pattern editing screen is finished

To select a pattern and start a new operation 3Touch

If the machine was turned off while embroidering

Turn off the embroidery machine

Changing the Needle

Replacing the needle

Changing the Needle

Other Basic Procedures

Correctly Using the Embroidery Frames

Correctly Using the Embroidery Frames

Embroidery frame types and applications

Attaching Iron-On Stabilizer Backing to Fabric

Hooping the Fabric

Hooping the Fabric

Using the embroidery sheet

Embroidering the corner of fabric

Large/small pieces of fabric

Embroidering large pieces of fabric or heavy clothing

Embroidering small pieces of fabric

Embroidery frames that cannot be used for embroidering

Embroidery Frame Position and Movement

Moving to the correct position

Embroidery Frame Position and Movement

Needle and presser foot are locked in the down position

Touch Embroidering settings screen

Changing the Embroidering Position

Finding the sewing position

Screen shown below appears Example Original angle

Adjusting the angle

Changing the Embroidering Position

Needle bar is unlocked

4If necessary, touch to check the embroidering area

2Touch the keys to adjust the pattern to the desired angle

After making the desired changes, touch

Embroidering a Pattern Containing Seven or More Colors

Embroidering a Pattern Containing Seven or More Colors

Checking if thread spool

Changes are necessary

3Check the position

Spool change indicator

1Touch in the embroidering screen

Stitch navigating screen appears

Change thread spools message

For details, refer to Reserved Needle Bar Settings on

Easily changing the thread spools

Repage-thread35.the upper thread. Refer to Touch

If the upper thread breaks

1Touch , and then press the thread trimming button

If the bobbin thread breaks or runs out

Touch To start sewing from the beginning

Embroidering From the Beginning or Middle of the Pattern

Embroidering From the Beginning or Middle of the Pattern

1Pressmachine.the start/stop button to stop

Embroidering begins from the specified point

4After selecting the stitch from where

Resume Embroidering After Turning OFF the Machine

Resume Embroidering After Turning OFF the Machine

Sewn

Embroidering screen displayed before

Machine can be stopped at any time

Weight S is included with the optional bobbin winder

Adjusting the Thread Tension

Adjusting the tension of the bobbin thread

Adjusting the Thread Tension

Upper thread is too loose

Adjusting the tension of the upper thread

Turn the thread tension knobs

Upper thread is too tight

Embroidering Settings

Setting turned on Setting turned off

Automatic Lock Stitch Setting

1Touch So that it changes to

Starting/Ending Position Settings

Starting/Ending Position Settings

Starting/ending position settings screen appears

2Sew the first embroidery pattern

Repeatedly sewing a pattern along a diagonal

4Repeat steps 2 and 3 three times

Maximum Sewing Speed Setting

Maximum Sewing Speed Setting

Stopping the machine at the next color change

Setting the Machine to Stop at Color Changes

Specifying pause locations before embroidering

3Touch so that it changes to

Setting the Machine to Stop at Color Changes

Mark appears to indicate where the machine will stop

After specifying the desired settings, touch

Temporary Needle Bar Setting

Temporary Needle Bar Setting

3Selectbar. the color to be assigned to the needle

Reserved Needle Bar Settings

Color selected in is specified

This cancels the manual needle bar setting

Reserved Needle Bar Settings

Cancelling the setting

Wish to cancel

Embroidering Settings

Machine’s Memory If the Embroidery Pattern Cannot Be Saved

General pattern selection Embroidery patterns

Embroidery cards optional Computer USB

Rotating the entire pattern Creating a repeating pattern

100

Embroidery Data Precautions

Embroidery Data Precautions

Precautions on using the computer to create data

102

General pattern selection

Please refer to page 5 for a list of compatible cards

Off

104

Embroidery patterns

3If necessary, edit the pattern

List of renaissance alphabet patterns appears

Renaissance Alphabet Patterns

2Select an embroidery pattern. Touch the desired pattern

106

Floral alphabet patterns

4Touch Select an embroidery pattern

4If necessary, edit the pattern

Appliqué alphabet

2Select the text size

3Select an embroidery pattern. Touch the desired pattern

108

Frame patterns

List of frame patterns appears

2Select a character font

Alphabet patterns

There are 13 built-in character fonts

Font selection screen appears

Selected characters appear in the pattern display area

110

Changing the size

Size of the two small fonts Cannot be changed

8After entering all of the text as desired, touch

Embroidery patterns stored in the machine

Changing the text arrangement

Touch to return to the text input screen

112

Embroidery cards optional

Deleting embroidery data

List of patterns on the embroidery card appears

Computer USB

Connecting

114

List of patterns is displayed

116

Insert the USB media into the machine’s USB Type a host port

USB media Commercially Available

118

2Select an embroidery pattern

Editing the Embroidery Pattern Pattern Editing Screen

Combining patterns

Editing the Embroidery Pattern Pattern Editing Screen

Touch or

Selecting the pattern to be edited

Moving a pattern

120

Screen shown below appears Example Original size

Flipping a pattern horizontally

Flipping a pattern vertically

Changing the size of a pattern

4After making the desired changes, touch

2Touch the keys to adjust the pattern to the desired size

Rotating a pattern

122

Screen shown below appears

Changing the text arrangement of a character

124

Changing the character spacing

Selects a more thread density

Changing the thread density

Trimming the threads between characters

Selects a less thread density

3After making the desired changes, touch

Specifying multi-color text

126

2Touchdensity.the keys to select the desired thread

Changing the colors of the pattern

128

Deleting a pattern

If necessary, touch

Editing the Embroidery Pattern Embroidering Settings Screen

Editing the Embroidery Pattern Embroidering Settings Screen

Rotating the entire pattern

3Touch , , or to

Creating a repeating pattern

130

2Touch , , or to

2Forpagedetails127. on changing the colors, refer to

4If necessary, touch the arrow keys to adjust

After specifying the desired repeat settings Touch

5embroidering area

1Touch 2Select

Editing a Combined Pattern

132

Will then edit

8After selecting the characters, touch

9Touch and adjust the position of the letters

Editing a Combined Pattern

Touch 7Type ood

Example To reduce

134

BTouch to select the same font, and then type Luck

To select the pattern to be edited

JAfter finishing all editing, touch

136

Saving Embroidery Patterns

Machine’s Memory

If the Embroidery Pattern Cannot Be Saved

Recalling stored patterns

Saving Embroidery Patterns

4To delete the data, press

Saving the data takes approximately 10 seconds

3Press

138

Changing the display guides

Basic Settings and Help Feature

Understanding the settings screen

Using the Settings Key

140

Reserved Needle

Using the Settings Key

142

Adjusting the brightness of the LCD

1Touch or and select the desired setting

Turning the buzzer on or off

Changing the units of measurements

Changing the language

Changing the display guides

Centerpoint marker and grid are displayed as specified

144

Embroidering area of the large embroidery frame

Centerpoint marker and grid

Sample displays

Changing the thread color information

Center Cursor

1Touch and to select the desired thread color display

Original Thread

Display expanded thread color

146

Thread color number Robison-Anton Time

Touchdesired thread. or to select

Custom thread table settings

2Touch and to select the thread

Creating a custom thread

3Select the thread color number type

148

4Type in the thread color number

Changing the color thread table

150

1Touch and to select the setting

Deleting short stitches

Specifying the remaining length of thread

Procedure for threading the upper thread appears

Using the Machine Operations Guide Key

Using the Machine Operations Guide Key

Touch Troubleshooting Maintenance

Screen that was displayed before was touched appears

After checking the procedure, touch Touch

152

4Touch to display the next

Using the Help Key

Using the Help Key

Example Viewing help on the function keys

154

Helpful Tips for the Operation of PR-600

Precautions

Sewing appliqué patterns

Additional digitizing information

156

Procedure for sewing appliqués

Appliqué Sewing

Sewing appliqué patterns

Appliqué Sewing

Using a frame pattern to create appliqués

7Finish sewing the embroidery

158

Select the satin-stitched frame pattern with the same shape

3Touch 1Touch 4Touch 2Touch 1 times, and then touch 5Touch

Helpful Tips for the Operation of PR-600II

Checking the thread tension of built-in patterns

160

Helpful Tips for the Operation of PR-600II

Sewing a pattern aligned with a mark on the fabric

3Withfabric.a fabric marker, mark this point on

162

Withfabric.a fabric marker, mark this point on

Colors of Tajima .dst embroidery data

Color thread table

Threads

Creating Beautiful Embroidery

164

Creating Beautiful Embroidery

Stabilizers Backing

Backing must not be visible in the finished Product.7

166

Hooping Techniques

Frame Basics

Fabric/stabilizer compatibility chart

168

Optional Accessories

Cap frame and its accessories

Using the Optional Cap Frame

Using the Optional Cap Frame

170

Types of caps

Cap fabric not recommended for embroidering

Fabric precautions

Installing the cap frame driver

Preparing to use the cap frame

172

This completes the installation of the cap frame driver

Do not loosen them too far

Adjusting the cap frame driver

Preparing the mounting jig

174

Firmly tighten the screws

Attach the needle plate spacer to the needle plate

Check that there is no looseness

2Tighten the two screws

For the standard type

176

Attach the standard cap frame to the mounting jig

3Placing a sheet of stabilizer

Check for the following conditions

178

Make sure the notch comes out

BRemove the standard cap frame from the mounting jig

180

Attach the advanced cap frame to the mounting jig

3Secureframe. the stabilizer with the pins on the cap

182

Remove the advanced cap frame from the mounting jig

DAdjustshape. the brim so that it maintains a rounded

Attaching the cap frame to the embroidery machine

184

Removing the cap frame

2Loosen the two lower thumb screws

Installing the embroidery frame holder

4Remove the cap frame driver

Remove the needle plate spacer

186

Additional digitizing information

Don’t sew more than four overlapping layers

For precautions concerning the power supply, refer to

Using the Optional Bobbin Winder

Precautions

Optional bobbin winder and its accessories

2Insert the thread guide

Setting up the optional bobbin winder

Connecting the AC adapter

Using the Optional Bobbin Winder

190

Winding the bobbin

2Set the thread spool on the spool pin

8Slideplace.the bobbin holder, until it clicks into

Press the main power switch to start winding the bobbin

ARemove the bobbin

192

Cleaning the hook

Maintenance

Cleaning the LCD

Cleaning the machine surface

194

Cleaning around the needle plate

Cleaning the bobbin case

196

Oiling the machine

Put a drop of oil onto the hook

Be sure to rotate the handwheel counterclockwise

On-screen troubleshooting

Troubleshooting

198

Dealer Presser foot

Troubleshooting

Troubleshooting

Breaks

Upper thread is catching

200

Needle is touching the needle plate Upper thread

Area

202

Upper or middle thread guide

Needle plate or in the hook Plate

Clean the hook and the needle Skipped

204

Thread Embroidering Short Begins

Dealer Bent

Be read

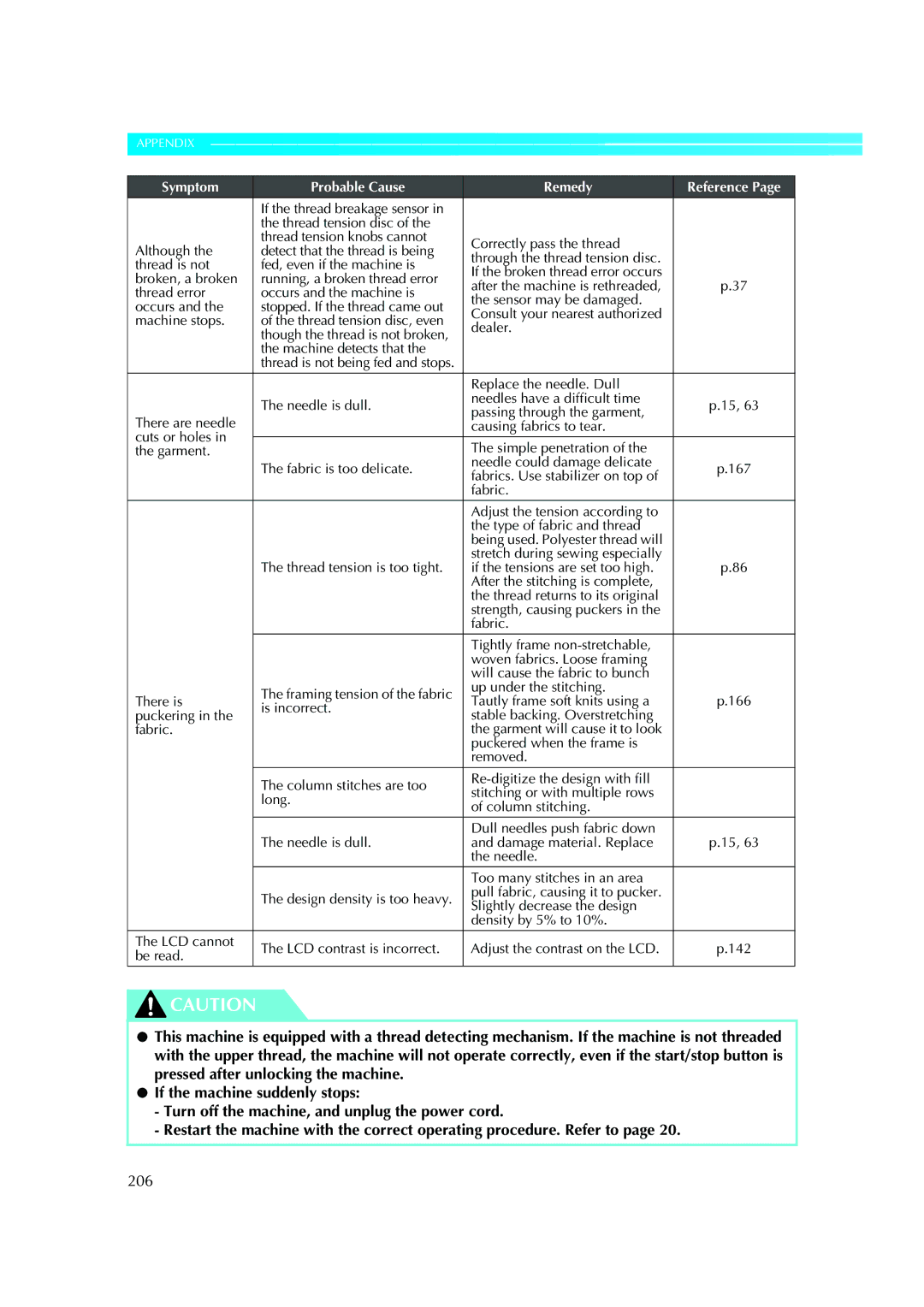

206

Fabrics. Use stabilizer on top

Is incorrect

Installed embroidery frame is too small

Error messages

Bobbin thread was broken or ran out

208

Thread color that was specified is incorrect

Patterns stored in the machines memory cannot be recalled

USB media is write-pro- tected

Machine couldnt save the data

Embroidery data may be damaged

USB media error

210

Embroidery data cannot be detected

Troubleshooting

212

If the LCD cannot be read

Adjustments screen appears

214

Specification

Specifications

Embroidery machine specifications

Specifications

216

Index

LCD

Index

218

Index

English