MAINTENANCE

MAINTENANCE

The Bush Hog 100 Series is a rugged, heavy duty Blade that will perform satisfactorily with the following preventive maintenance.

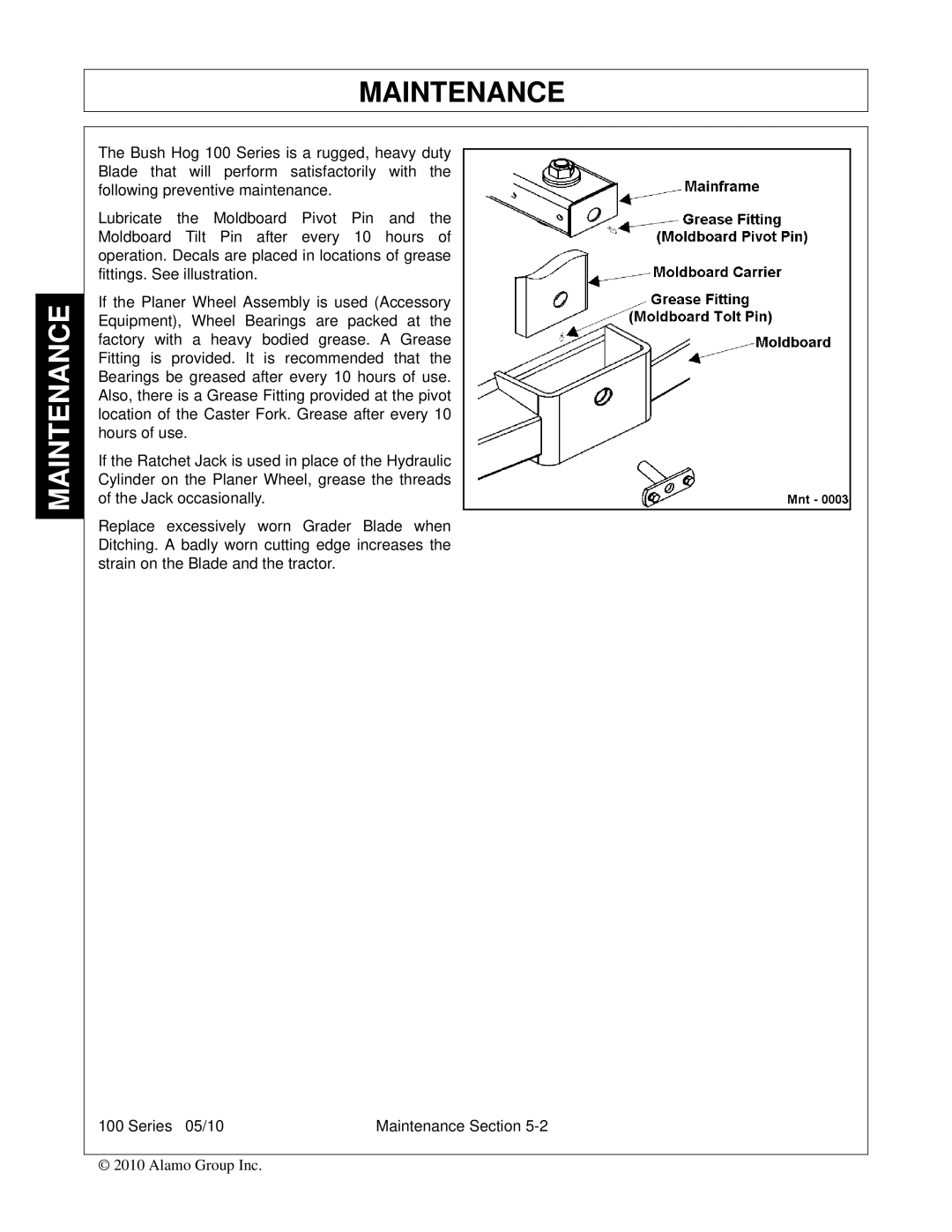

Lubricate the Moldboard Pivot Pin and the Moldboard Tilt Pin after every 10 hours of operation. Decals are placed in locations of grease fittings. See illustration.

If the Planer Wheel Assembly is used (Accessory Equipment), Wheel Bearings are packed at the factory with a heavy bodied grease. A Grease Fitting is provided. It is recommended that the Bearings be greased after every 10 hours of use. Also, there is a Grease Fitting provided at the pivot location of the Caster Fork. Grease after every 10 hours of use.

If the Ratchet Jack is used in place of the Hydraulic Cylinder on the Planer Wheel, grease the threads of the Jack occasionally.

Replace excessively worn Grader Blade when Ditching. A badly worn cutting edge increases the strain on the Blade and the tractor.

100 Series 05/10 | Maintenance Section |

© 2010 Alamo Group Inc.