139/150-Hour Maintenance (continued)

3.Insert 0.10 mm (0.004 in.) feeler gauge between valve stem tip and rocker arm.

4.Turn adjustment screw (clockwise = tighter,

just enough to allow gauge to slip out with limited resistance.

5.While holding adjustment screw in place with Allen driver, tighten locknut with wrench.

6.Turn engine over several times, and return to

7.Replace rocker arm cover gasket to as- sure proper sealing and install cover.

IMPORTANT!

If new gasket is not available and/or old gasket is not damaged, old gasket may be reused. Never use cracked or damaged gaskets!

Spark Arrester Maintenance

![]() WARNING!

WARNING!

Never operate this blower with a dam- aged or missing muffler or spark arrest- er! Operating with missing or damaged exhaust components is a fire hazard,

and can also damage your hearing!

.

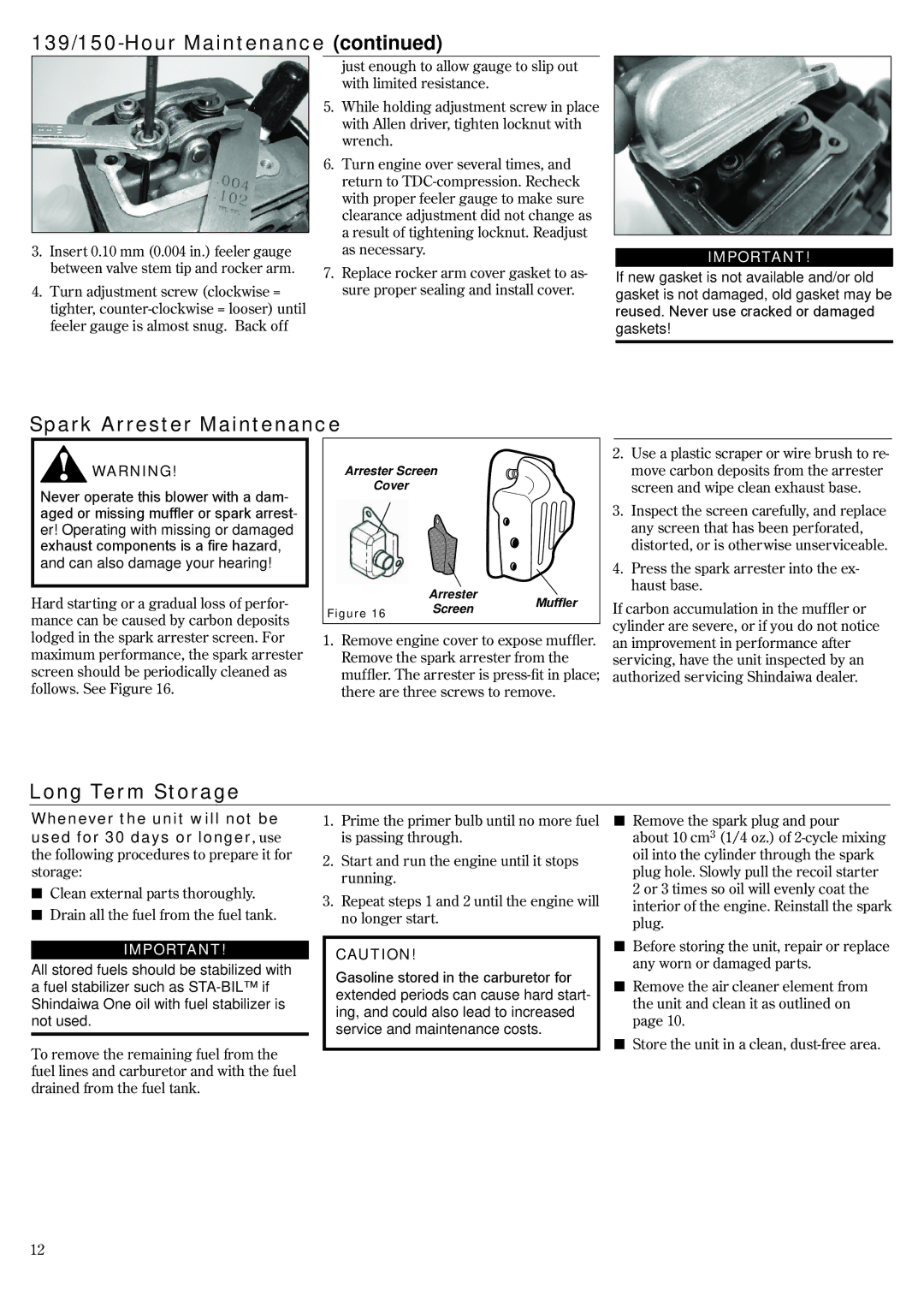

Hard starting or a gradual loss of perfor- mance can be caused by carbon deposits lodged in the spark arrester screen. For maximum performance, the spark arrester screen should be periodically cleaned as follows. See Figure 16.

Arrester Screen

Cover

| Arrester | Muffler | |

Figure 16 | Screen | ||

|

1.Remove engine cover to expose muffler. Remove the spark arrester from the muffler. The arrester is

2.Use a plastic scraper or wire brush to re- move carbon deposits from the arrester screen and wipe clean exhaust base.

3.Inspect the screen carefully, and replace any screen that has been perforated, distorted, or is otherwise unserviceable.

4.Press the spark arrester into the ex- haust base.

If carbon accumulation in the muffler or cylinder are severe, or if you do not notice an improvement in performance after servicing, have the unit inspected by an authorized servicing Shindaiwa dealer.

Long Term Storage

Whenever the unit will not be used for 30 days or longer, use the following procedures to prepare it for storage:

nClean external parts thoroughly.

nDrain all the fuel from the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with a fuel stabilizer such as

To remove the remaining fuel from the fuel lines and carburetor and with the fuel drained from the fuel tank.

1.Prime the primer bulb until no more fuel is passing through.

2.Start and run the engine until it stops running.

3.Repeat steps 1 and 2 until the engine will no longer start.

CAUTION!

Gasoline stored in the carburetor for extended periods can cause hard start- ing, and could also lead to increased service and maintenance costs.

nRemove the spark plug and pour

about 10 cm3 (1/4 oz.) of

nBefore storing the unit, repair or replace any worn or damaged parts.

nRemove the air cleaner element from the unit and clean it as outlined on. page 10.

nStore the unit in a clean,

12