Assembly

SYSTEM SETUP

Using fittings or air hoses which are too small can create a pressure drop which will result in a loss of power in the tool.

NOTE: Do not install a quick coupler set between the tool and whip hose.

Do not misuse this

!WARNING product. Excessive exposure to vibration, work in awk- ward positions and repetitive work motions can cause injury to hands and arms. Stop using any tool if discomfort, numbness, tingling or pain occur, and consult a physician.

Never carry a tool ! WARNING by the hose or pull

the hose to move the tool or a compressor. Keep hoses away from heat, oil and sharp edges. Replace any hose that is damaged, weak or worn.

Pre-Operation

Air tools require lubrication through- out the life of the tool. Proper lubrication is the owner’s responsibility. Use airtool oil to lubricate, clean and

3.Connect the chisel/hammer to the air supply and cover the exhaust port with a towel. Run the chisel/hammer for 7 to 10 seconds. Oil will discharge from the exhaust port when air pressure is applied. If the piston does not cycle, install a bit into the spring retainer. Be careful not to allow the towel to catch in the spring retainer.

Operation

SPRING RETAINER

The spring retainer holds the hammer in place. The retainer must be securely attached (See Figure 1). The retainer is a normal wear item and should be replaced when worn. Replace with MP2896 (2) piece hammer spring set. The retainer unscrews for easy hammer insertion.

| Spring | B. Press tab and |

| Retainer |

| twist clockwise |

| |

| | to tighten |

| | spring retainer, |

| | firmly securing |

| | chisel bit |

wear item and should be replaced when worn. Replace with PA1039.

REGULATOR

Some air hammers are equipped with a built-in air regulator to reduce the blow rate. It is located next to the air inlet. Turn the knob counter-clockwise for the fully open, highest speed. Gradually turn the knob clockwise to reduce the speed (See Figure 3).

Air Inlet

Maintenance

STORAGE

The chisel/hammer must be lubricated before storing. Follow the air piston lubrication instructions with an exception to step 3. Only run the

REGULADOR

Algunos martillos neumáticos vienen equipados con un regulador de aire integral para reducir la frecuencia de los golpes. Está ubicado cerca de la entrada de aire. Gire la perilla en sentido antihorario para la apertura total y velocidad máxima. Gire gradualmente la perilla en sentido horario para reducir la velocidad (Ver Figura 3).

Entrada de aire

Mantenimiento

ALMACENAMIENTO

Este cincel/martillo debe lubricarse antes de ser almacenado. Siga las

instrucciones de lubricación del pistón neumático con una excepción al paso

3.Sólo haga funcionar el cincel/martillo durante 2s a 3s en vez de los 7 a 10, debido a que debe permanecer más aceite en el cincel/martillo al almacenarlo.

Servicio Técnico

Para obtener información acerca del funcionamiento o reparación de este producto, sírvase llamar al 1-800-543-6400.

Información Sobre las Piezas de Repuesto

Para obtener información sobre dónde pedir las piezas de repuesto, llame al

1-800-543-8622 (sin costo). Proporcione la siguiente información:

•Número del modelo

•Código estampado

•Número de pieza y descripción

Envíe su correspondencia sobre las piezas a:

Campbell Hausfeld

100 Production Drive Harrison, Ohio 45030 U.S.A.

NOTA: Los martillo no se incluyen con algunas herramientas. Se puede utilizar cualquier martillo con espiga cónica 0,401 Campbell Hausfeld. Campbell Hausfeld ofrece cinco martillo utilizados comúnmente (Número de pieza PA1003 o MP2875*).

*PA1003 es un juego de cinco piezas de martillo,

y cada una mide 15,24 cm (6") de largo. MP2875 es un juego de cuatro piezas de martillo, y cada una mide 7,62 cm (3") de largo (No incluye el cortador de hoja metálica.

Separador de

Puntos de

Soldadura

Separador

Troquel

Plano

Cortador de

Hosjas

Metálicas

Figura 4 - Brocas para Cince

inhibit rust in one step. Failure to lubricate and maintain the air tool properly will dramatically shorten the life of the tool and will void the warranty.

This air

NOTICE tool

requires lubrication before initial use and before and after each additional use.

AIR PISTON LUBRICATION

The air piston must be lubricated daily. An air piston cannot be oiled too often.

Disconnect the

! CAUTION chisel/hammer from the air supply before lubricating.

1. Turn the chisel/hammer upside down.

A. Press tab here and twist counter-clockwise to release spring retainer and insert chisel bit

Figure 1 - Spring Retainer

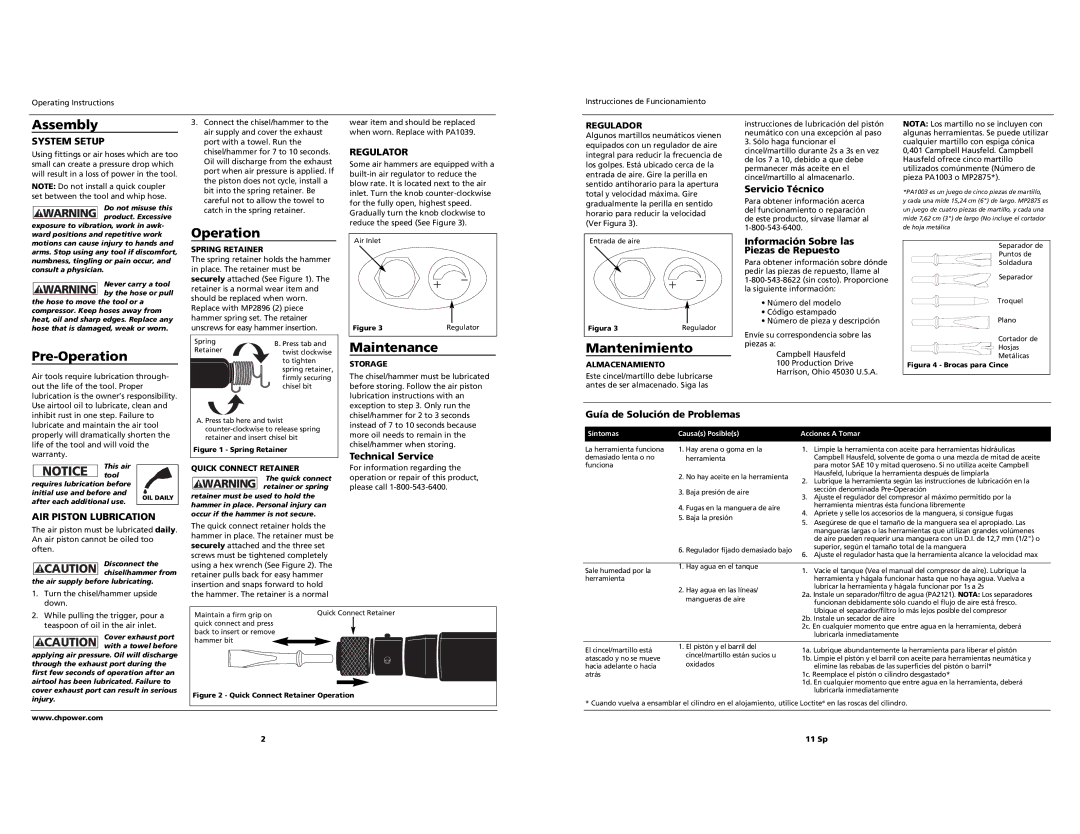

QUICK CONNECT RETAINER

The quick connect ! WARNING retainer or spring

retainer must be used to hold the hammer in place. Personal injury can occur if the hammer is not secure.

The quick connect retainer holds the hammer in place. The retainer must be securely attached and the three set screws must be tightened completely using a hex wrench (See Figure 2). The retainer pulls back for easy hammer insertion and snaps forward to hold the hammer. The retainer is a normal

chisel/hammer for 2 to 3 seconds instead of 7 to 10 seconds because more oil needs to remain in the chisel/hammer when storing.

Technical Service

For information regarding the operation or repair of this product, please call 1-800-543-6400.

Guía de Solución de Problemas

| Síntomas | Causa(s) Posible(s) | Acciones A Tomar |

| La herramienta funciona | 1. Hay arena o goma en la | 1. | Limpie la herramienta con aceite para herramientas hidráulicas |

| demasiado lenta o no | herramienta | | Campbell Hausfeld, solvente de goma o una mezcla de mitad de aceite |

| funciona | | | para motor SAE 10 y mitad queroseno. Si no utiliza aceite Campbell |

| | 2. No hay aceite en la herramienta | | Hausfeld, lubrique la herramienta después de limpiarla |

| | 2. | Lubrique la herramienta según las instrucciones de lubricación en la |

| | |

| | 3. Baja presión de aire | | sección denominada Pre-Operación |

| | 3. | Ajuste el regulador del compresor al máximo permitido por la |

| | |

| | 4. Fugas en la manguera de aire | | herramienta mientras ésta funciona libremente |

| | 4. | Apriete y selle los accesorios de la manguera, si consigue fugas |

| | 5. Baja la presión |

| | 5. | Asegúrese de que el tamaño de la manguera sea el apropiado. Las |

| | |

| | | | mangueras largas o las herramientas que utilizan grandes volúmenes |

| | | | de aire pueden requerir una manguera con un D.I. de 12,7 mm (1/2") o |

| | 6. Regulador fijado demasiado bajo | | superior, según el tamaño total de la manguera |

| | 6. | Ajuste el regulador hasta que la herramienta alcance la velocidad max |

| | |

| | | | |

| Sale humedad por la | 1. Hay agua en el tanque | 1. | Vacíe el tanque (Vea el manual del compresor de aire). Lubrique la |

| |

| herramienta | | | herramienta y hágala funcionar hasta que no haya agua. Vuelva a |

| | 2. Hay agua en las líneas/ | | lubricar la herramienta y hágala funcionar por 1s a 2s |

| | 2a. Instale un separador/filtro de agua (PA2121). NOTA: Los separadores |

| | mangueras de aire |

| | | funcionan debidamente sólo cuando el flujo de aire está fresco. |

| | | |

2.While pulling the trigger, pour a teaspoon of oil in the air inlet.

Cover exhaust port with a towel before applying air pressure. Oil will discharge

through the exhaust port during the first few seconds of operation after an airtool has been lubricated. Failure to cover exhaust port can result in serious injury.

Maintain a firm grip on | Quick Connect Retainer |

|

quick connect and press | |

back to insert or remove | |

hammer bit | |

Figure 2 - Quick Connect Retainer Operation

| | | Ubique el separador/filtro lo más lejos posible del compresor |

| | | 2b. Instale un secador de aire |

| | | 2c. En cualquier momento que entre agua en la herramienta, deberá |

| | | lubricarla inmediatamente |

| | | |

| El cincel/martillo está | 1. El pistón y el barril del | 1a. Lubrique abundantemente la herramienta para liberar el pistón |

| cincel/martillo están sucios u |

| atascado y no se mueve | 1b. Limpie el pistón y el barril con aceite para herramientas neumática y |

| oxidados |

| hacia adelante o hacia | elimine las rebabas de las superficies del pistón o barril* |

| |

| atrás | | 1c. Reemplace el pistón o cilindro desgastado* |

| | | 1d. En cualquier momento que entre agua en la herramienta, deberá |

| | | lubricarla inmediatamente |

* Cuando vuelva a ensamblar el cilindro en el alojamiento, utilice Loctite® en las roscas del cilindro.