Operating Instructions | Model SB323200 |

Modelo SB323200

General Safety Information (Continued)

●Never carry the tool by the air hose or pull the hose to move the tool or a compres- sor. Keep hoses away from heat,

oil and sharp edges. Replace any hose that is damaged, weak or worn. Personal injury or tool dam- age could occur.

●Always assume the nailer contains nails. Respect the tool as a working implement; no horseplay. Always keep others at a safe distance from the work area in case of accidental discharge of nails. Do not point the tool toward yourself or anyone whether it contains fasteners or not. Accidental triggering of the nailer could result in death or serious per- sonal injury.

●Do not operate

or allow anyone else to operate the tool if any warnings or warning labels are not legible.

Warnings or warning labels are locat- ed on the tool magazine and body.

●Always check that the Work Contact Element (WCE) is operating properly. A nail

could acciden- tally be driven if the WCE is

not working properly. Personal injury may occur (See “Checking the Work Contact Element” Section).

●Disconnect air supply and release tension from the pusher before attempting to clear jams because fasteners can be ejected from the front of the tool. Personal injury may occur.

●Avoid using the tool when the mag- azine is empty. Accelerated wear on the tool may occur.

●Clean and check all air supply hoses and fittings before connecting the tool to an air supply. Replace any damaged or worn hoses or fittings. Tool performance or durability may be reduced.

●Air compressors providing air to the tool should follow the requirements established by the American National Standards Institute Standard

Operating The Tool

LUBRICATION

This tool requires lubrication before using the tool for the first time and before each use. If an inline oiler is used, manual lubrication through the air inlet is not required on a daily basis.

The work surface NOTICE can become dam-

aged by excessive lubrication. Proper lubrication is the owner’s responsibil- ity. Failure to lubricate the tool proper- ly will dramatically shorten the life of the tool and void the warranty.

1. Disconnect the air supply from the tool to add lubricant.

2.Turn the tool so the

air inlet is facing up. OIL

Place

use detergent oils,

oil additives, or air tool oils. Air tool oils contain solvents which will dam- age the tool's internal components.

3. After adding oil, run tool briefly. Wipe off any excess oil from the cap exhaust.

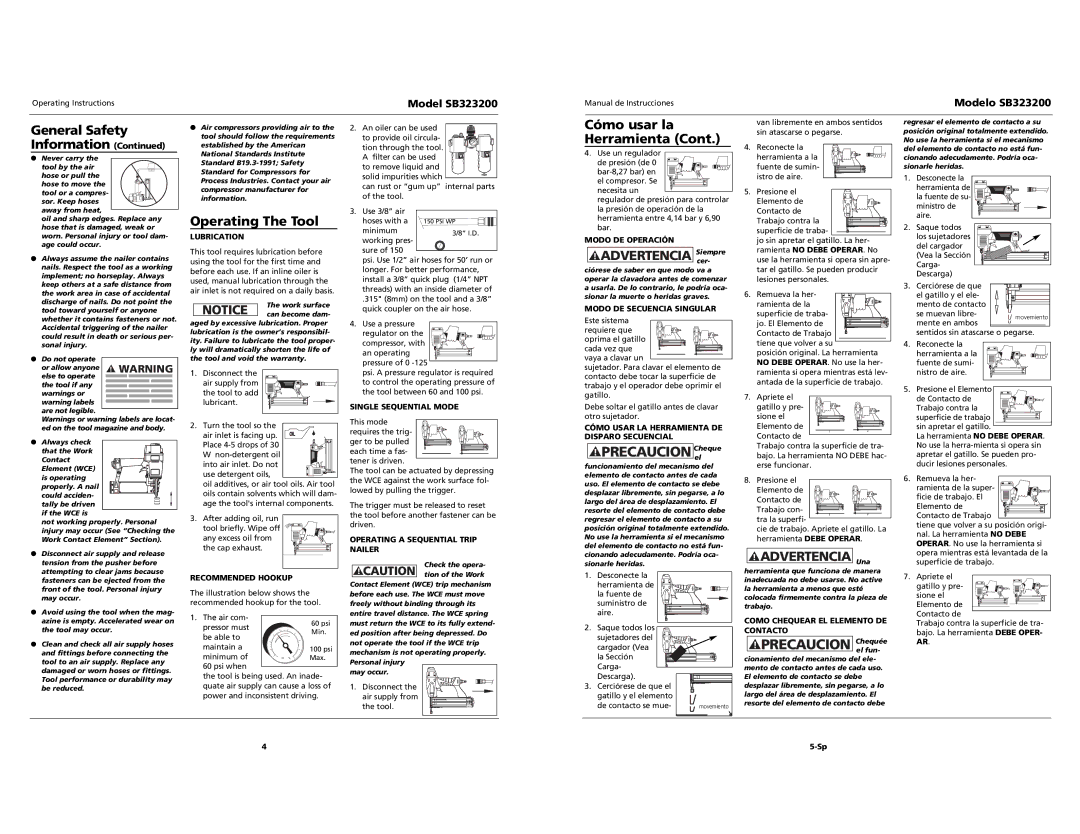

RECOMMENDED HOOKUP

The illustration below shows the recommended hookup for the tool.

1. The air com- pressor must be able to

maintain a minimum of 60 psi when

the tool is being used. An inade- quate air supply can cause a loss of power and inconsistent driving.

2. An oiler can be used

to provide oil circula- tion through the tool.

A filter can be used ![]()

![]()

![]()

![]() to remove liquid and

to remove liquid and ![]()

![]() solid impurities which

solid impurities which ![]() can rust or “gum up”

can rust or “gum up”

of the tool.

3. Use 3/8” air

hoses with a minimum

working pres- sure of 150

psi. Use 1/2” air hoses for 50’ run or longer. For better performance, install a 3/8” quick plug (1/4” NPT threads) with an inside diameter of

.315" (8mm) on the tool and a 3/8” quick coupler on the air hose.

4. Use a pressure

regulator on the compressor, with

an operating pressure of 0

psi. A pressure regulator is required to control the operating pressure of the tool between 60 and 100 psi.

SINGLE SEQUENTIAL MODE

This mode requires the trig-

ger to be pulled each time a fas- tener is driven.

The tool can be actuated by depressing the WCE against the work surface fol- lowed by pulling the trigger.

The trigger must be released to reset the tool before another fastener can be driven.

OPERATING A SEQUENTIAL TRIP NAILER

Check the opera- tion of the Work

Contact Element (WCE) trip mechanism before each use. The WCE must move freely without binding through its entire travel distance. The WCE spring must return the WCE to its fully extend- ed position after being depressed. Do not operate the tool if the WCE trip mechanism is not operating properly. Personal injury

may occur.

1.Disconnect the air supply from the tool.

van libremente en ambos sentidos sin atascarse o pegarse.

4.Reconecte la herramienta a la fuente de sumin- istro de aire.

5.Presione el Elemento de Contacto de Trabajo contra la superficie de traba-

jo sin apretar el gatillo. La her- ramienta NO DEBE OPERAR. No use la herramienta si opera sin apre- tar el gatillo. Se pueden producir lesiones personales.

6.Remueva la her- ramienta de la superficie de traba-

jo. El Elemento de Contacto de Trabajo tiene que volver a su

posición original. La herramienta NO DEBE OPERAR. No use la her- ramienta si opera mientras está lev- antada de la superficie de trabajo.

7.Apriete el gatillo y pre-

sione el |

|

Elemento de | 2 |

1 | |

Contacto de |

|

Trabajo contra la superficie de tra- | |

bajo. La herramienta NO DEBE hac- | |

erse funcionar. |

|

8. Presione el |

|

Elemento de |

|

Contacto de |

|

Trabajo con- | 2 |

1 | |

tra la superfi- |

|

cie de trabajo. Apriete el gatillo. La herramienta DEBE OPERAR.

!ADVERTENCIA Una

herramienta que funciona de manera inadecuada no debe usarse. No active la herramienta a menos que esté colocada firmemente contra la pieza de trabajo.

COMO CHEQUEAR EL ELEMENTO DE CONTACTO

Chequée el fun-

cionamiento del mecanismo del ele- mento de contacto antes de cada uso. El elemento de contacto se debe desplazar libremente, sin pegarse, a lo largo del área de desplazamiento. El resorte del elemento de contacto debe

regresar el elemento de contacto a su posición original totalmente extendido. No use la herramienta si el mecanismo del elemento de contacto no está fun- cionando adecudamente. Podría oca- sionarle heridas.

1. Desconecte la herramienta de la fuente de su- ministro de aire.

2. Saque todos los sujetadores del cargador (Vea la Sección Carga- Descarga)

3.Cerciórese de que el gatillo y el ele- mento de contacto

| se muevan libre- | movemiento |

| mente en ambos | |

|

| |

| sentidos sin atascarse o pegarse. | |

4. | Reconecte la |

|

| herramienta a la |

|

| fuente de sumi- |

|

| nistro de aire. |

|

5. | Presione el Elemento |

|

| de Contacto de |

|

| Trabajo contra la |

|

| superficie de trabajo |

|

| sin apretar el gatillo. |

|

| La herramienta NO DEBE OPERAR. | |

| No use la | |

| apretar el gatillo. Se pueden pro- | |

| ducir lesiones personales. |

|

6. Remueva la her- |

| |

| ramienta de la super- |

|

| ficie de trabajo. El |

|

| Elemento de |

|

| Contacto de Trabajo |

|

| tiene que volver a su posición origi- | |

| nal. La herramienta NO DEBE | |

| OPERAR. No use la herramienta si | |

| opera mientras está levantada de la | |

| superficie de trabajo. |

|

7. | Apriete el |

|

| gatillo y pre- |

|

| sione el |

|

| Elemento de |

|

| Contacto de |

|

| Trabajo contra la superficie de tra- | |

| bajo. La herramienta DEBE OPER- | |

| AR. |

|

4 |