Operating The Tool

(Continued)

3. After adding oil, run tool briefly. Wipe off any excess oil from the cap exhaust.

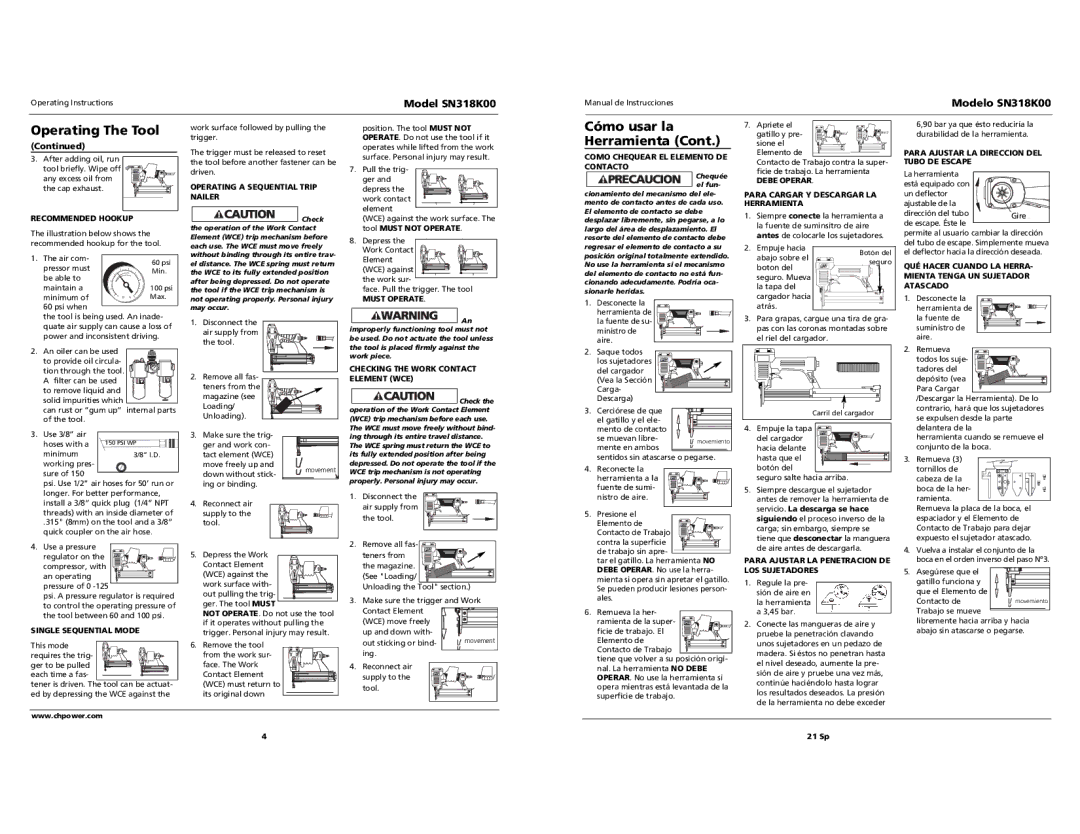

RECOMMENDED HOOKUP

The illustration below shows the recommended hookup for the tool.

work surface followed by pulling the trigger.

The trigger must be released to reset the tool before another fastener can be driven.

OPERATING A SEQUENTIAL TRIP NAILER

Check the operation of the Work Contact Element (WCE) trip mechanism before

Check the operation of the Work Contact Element (WCE) trip mechanism before

position. The tool MUST NOT OPERATE. Do not use the tool if it operates while lifted from the work surface. Personal injury may result.

7.Pull the trig- ger and

depress the work contact

12

element

(WCE) against the work surface. The tool MUST NOT OPERATE.

Cómo usar la Herramienta (Cont.)

COMO CHEQUEAR EL ELEMENTO DE CONTACTO

Chequée el fun-

cionamiento del mecanismo del ele- mento de contacto antes de cada uso. El elemento de contacto se debe desplazar libremente, sin pegarse, a lo largo del área de desplazamiento. El resorte del elemento de contacto debe

7. Apriete el

gatillo y pre- sione el

Elemento de

Contacto de Trabajo contra la super- ficie de trabajo. La herramienta

DEBE OPERAR.

PARA CARGAR Y DESCARGAR LA HERRAMIENTA

1.Siempre conecte la herramienta a la fuente de suminsitro de aire antes de colocarle los sujetadores.

6,90 bar ya que ésto reduciría la durabilidad de la herramienta.

PARA AJUSTAR LA DIRECCION DEL TUBO DE ESCAPE

La herramienta

está equipado con un deflector ajustable de la dirección del tubo de escape. Éste le

permite al usuario cambiar la dirección del tubo de escape. Simplemente mueva

1. The air com- pressor must be able to maintain a minimum of 60 psi when

each use. The WCE must move freely without binding through its entire trav- el distance. The WCE spring must return the WCE to its fully extended position after being depressed. Do not operate the tool if the WCE trip mechanism is not operating properly. Personal injury may occur.

Element | |

(WCE) against | 2 |

1 |

the work sur- | |

face. Pull the trigger. The tool

MUST OPERATE.

regresar el elemento de contacto a su posición original totalmente extendido. No use la herramienta si el mecanismo del elemento de contacto no está fun- cionando adecudamente. Podría oca- sionarle heridas.

1. Desconecte la herramienta de

2.Empuje hacia abajo sobre el boton del seguro. Mueva la tapa del cargador hacia atrás.

el deflector hacia la dirección deseada.

QUÉ HACER CUANDO LA HERRA- MIENTA TENGA UN SUJETADOR ATASCADO

1. Desconecte la herramienta de

the tool is being used. An inade- quate air supply can cause a loss of power and inconsistent driving.

1.Disconnect the air supply from

the tool.

An

improperly functioning tool must not be used. Do not actuate the tool unless

la fuente de su- ministro de aire.

3.Para grapas, cargue una tira de gra- pas con las coronas montadas sobre el riel del cargador.

la fuente de suministro de aire.

2. An oiler can be used to provide oil circula- tion through the tool. A filter can be used to remove liquid and solid impurities which can rust or “gum up” of the tool.

3. Use 3/8” air hoses with a minimum working pres- sure of 150

psi. Use 1/2” air hoses for 50’ run or longer. For better performance, install a 3/8” quick plug (1/4” NPT threads) with an inside diameter of

.315" (8mm) on the tool and a 3/8” quick coupler on the air hose.

2.Remove all fas- teners from the

magazine (see Loading/ Unloading).

| 3. Make sure the trig- | |

| ger and work con- | |

| tact element (WCE) | |

| move freely up and | movement |

| down without stick- |

| |

| ing or binding. | |

4.Reconnect air supply to the tool.

the tool is placed firmly against the work piece.

CHECKING THE WORK CONTACT ELEMENT (WCE)

Check the operation of the Work Contact Element (WCE) trip mechanism before each use. The WCE must move freely without bind- ing through its entire travel distance. The WCE spring must return the WCE to its fully extended position after being depressed. Do not operate the tool if the WCE trip mechanism is not operating properly. Personal injury may occur.

Check the operation of the Work Contact Element (WCE) trip mechanism before each use. The WCE must move freely without bind- ing through its entire travel distance. The WCE spring must return the WCE to its fully extended position after being depressed. Do not operate the tool if the WCE trip mechanism is not operating properly. Personal injury may occur.

1. Disconnect the air supply from the tool.

2. Saque todos los sujetadores del cargador (Vea la Sección Carga- Descarga)

3.Cerciórese de que el gatillo y el ele- mento de contacto

| se muevan libre- | movemiento |

| mente en ambos |

| |

| sentidos sin atascarse o pegarse. |

4. | Reconecte la | |

| herramienta a la | |

| fuente de sumi- | |

| nistro de aire. | |

5. | Presione el | |

| Elemento de | |

| Contacto de Trabajo | |

4. | Empuje la tapa |

| del cargador |

| hacia delante |

| hasta que el |

| botón del |

| seguro salte hacia arriba. |

5. Siempre descargue el sujetador |

antes de remover la herramienta de |

servicio. La descarga se hace |

siguiendo el proceso inverso de la |

carga; sin embargo, siempre se |

tiene que desconectar la manguera |

2. Remueva

todos los suje- tadores del

depósito (vea Para Cargar

/Descargar la Herramienta). De lo contrario, hará que los sujetadores se expulsen desde la parte delantera de la

herramienta cuando se remueve el conjunto de la boca.

3. Remueva (3) |

tornillos de |

cabeza de la |

boca de la her- |

ramienta. |

Remueva la placa de la boca, el |

espaciador y el Elemento de |

Contacto de Trabajo para dejar |

expuesto el sujetador atascado. |

4. Use a pressure

regulator on the compressor, with

an operating pressure of 0 -125

psi. A pressure regulator is required to control the operating pressure of the tool between 60 and 100 psi.

SINGLE SEQUENTIAL MODE

This mode

requires the trig-

ger to be pulled each time a fas-

tener is driven. The tool can be actuat- ed by depressing the WCE against the

5.Depress the Work Contact Element (WCE) against the work surface with- out pulling the trig- ger. The tool MUST

NOT OPERATE. Do not use the tool if it operates without pulling the trigger. Personal injury may result.

6.Remove the tool from the work sur-

face. The Work Contact Element (WCE) must return to its original down

2. Remove all fas- |

teners from |

the magazine. |

(See "Loading/ |

Unloading the Tool" section.) |

3.Make sure the trigger and Work Contact Element

(WCE) move freely up and down with-

out sticking or bind- | movement |

ing. | |

4. Reconnect air supply to the tool.

contra la superficie |

de trabajo sin apre- |

tar el gatillo. La herramienta NO |

DEBE OPERAR. No use la herra- |

mienta si opera sin apretar el gatillo. |

Se pueden producir lesiones person- |

ales. |

6. Remueva la her- |

ramienta de la super- |

ficie de trabajo. El |

Elemento de |

Contacto de Trabajo |

tiene que volver a su posición origi- |

nal. La herramienta NO DEBE |

OPERAR. No use la herramienta si |

opera mientras está levantada de la |

superficie de trabajo. |

de aire antes de descargarla. |

PARA AJUSTAR LA PENETRACION DE LOS SUJETADORES

1.Regule la pre- sión de aire en la herramienta a 3,45 bar.

2.Conecte las mangueras de aire y pruebe la penetración clavando unos sujetadores en un pedazo de madera. Si éstos no penetran hasta el nivel deseado, aumente la pre- sión de aire y pruebe una vez más, continúe haciéndolo hasta lograr los resultados deseados. La presión de la herramienta no debe exceder

4. | Vuelva a instalar el conjunto de la |

| boca en el orden inverso del paso Nº3. |

5. | Asegúrese que el |

| gatillo funciona y |

que el Elemento de

Contacto demovemiento Trabajo se mueve

libremente hacia arriba y hacia abajo sin atascarse o pegarse.