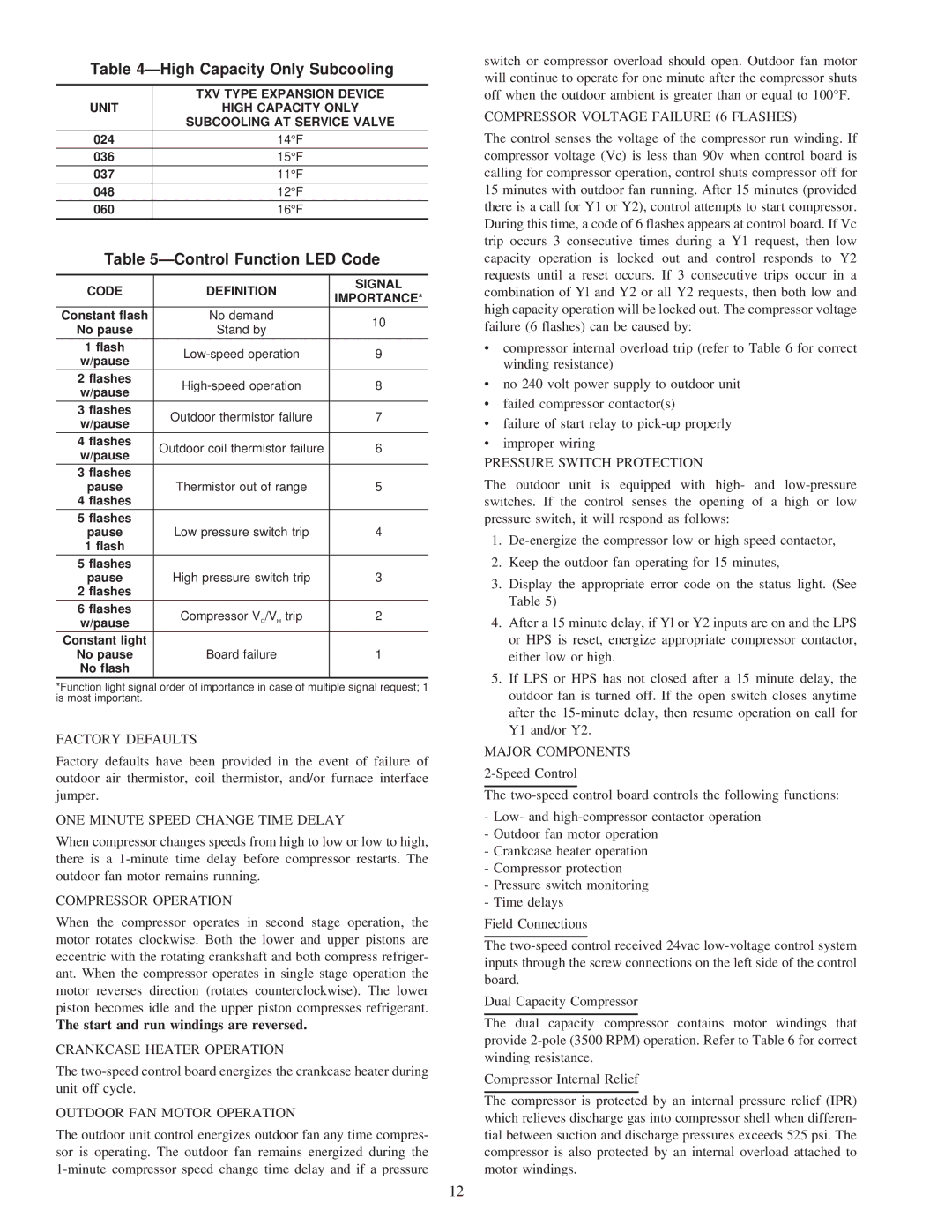

Table 4—High Capacity Only Subcooling

| TXV TYPE EXPANSION DEVICE |

UNIT | HIGH CAPACITY ONLY |

| SUBCOOLING AT SERVICE VALVE |

024 | 14°F |

036 | 15°F |

037 | 11°F |

048 | 12°F |

060 | 16°F |

|

|

Table 5—Control Function LED Code

CODE | DEFINITION | SIGNAL | |

IMPORTANCE* | |||

|

| ||

Constant flash | No demand | 10 | |

No pause | Stand by | ||

| |||

1 flash | 9 | ||

w/pause | |||

|

| ||

2 flashes | 8 | ||

w/pause | |||

|

| ||

3 flashes | Outdoor thermistor failure | 7 | |

w/pause | |||

|

| ||

4 flashes | Outdoor coil thermistor failure | 6 | |

w/pause | |||

|

| ||

3 flashes |

|

| |

pause | Thermistor out of range | 5 | |

4 flashes |

|

| |

5 flashes |

|

| |

pause | Low pressure switch trip | 4 | |

1 flash |

|

| |

5 flashes |

|

| |

pause | High pressure switch trip | 3 | |

2 flashes |

|

| |

6 flashes | Compressor VC/VH trip | 2 | |

w/pause | |||

|

| ||

Constant light |

|

| |

No pause | Board failure | 1 | |

No flash |

|

|

*Function light signal order of importance in case of multiple signal request; 1 is most important.

FACTORY DEFAULTS

Factory defaults have been provided in the event of failure of outdoor air thermistor, coil thermistor, and/or furnace interface jumper.

ONE MINUTE SPEED CHANGE TIME DELAY

When compressor changes speeds from high to low or low to high, there is a

COMPRESSOR OPERATION

When the compressor operates in second stage operation, the motor rotates clockwise. Both the lower and upper pistons are eccentric with the rotating crankshaft and both compress refriger- ant. When the compressor operates in single stage operation the motor reverses direction (rotates counterclockwise). The lower piston becomes idle and the upper piston compresses refrigerant.

The start and run windings are reversed.

CRANKCASE HEATER OPERATION

The

OUTDOOR FAN MOTOR OPERATION

The outdoor unit control energizes outdoor fan any time compres- sor is operating. The outdoor fan remains energized during the

switch or compressor overload should open. Outdoor fan motor will continue to operate for one minute after the compressor shuts off when the outdoor ambient is greater than or equal to 100°F.

COMPRESSOR VOLTAGE FAILURE (6 FLASHES)

The control senses the voltage of the compressor run winding. If compressor voltage (Vc) is less than 90v when control board is calling for compressor operation, control shuts compressor off for 15 minutes with outdoor fan running. After 15 minutes (provided there is a call for Y1 or Y2), control attempts to start compressor. During this time, a code of 6 flashes appears at control board. If Vc trip occurs 3 consecutive times during a Y1 request, then low capacity operation is locked out and control responds to Y2 requests until a reset occurs. If 3 consecutive trips occur in a combination of Yl and Y2 or all Y2 requests, then both low and high capacity operation will be locked out. The compressor voltage failure (6 flashes) can be caused by:

•compressor internal overload trip (refer to Table 6 for correct winding resistance)

•no 240 volt power supply to outdoor unit

•failed compressor contactor(s)

•failure of start relay to

•improper wiring

PRESSURE SWITCH PROTECTION

The outdoor unit is equipped with high- and

1.

2.Keep the outdoor fan operating for 15 minutes,

3.Display the appropriate error code on the status light. (See Table 5)

4.After a 15 minute delay, if Yl or Y2 inputs are on and the LPS or HPS is reset, energize appropriate compressor contactor, either low or high.

5.If LPS or HPS has not closed after a 15 minute delay, the outdoor fan is turned off. If the open switch closes anytime after the

MAJOR COMPONENTS

The

-Low- and

-Outdoor fan motor operation

-Crankcase heater operation

-Compressor protection

-Pressure switch monitoring

-Time delays

Field Connections

The

Dual Capacity Compressor

The dual capacity compressor contains motor windings that provide

Compressor Internal Relief

The compressor is protected by an internal pressure relief (IPR) which relieves discharge gas into compressor shell when differen- tial between suction and discharge pressures exceeds 525 psi. The compressor is also protected by an internal overload attached to motor windings.

12