AIR DISCHARGE | AIR IN |

AIR IN

C

L

3/8" DIA TIEDOWN KNOCKOUTS

(2) PLACES IN BASEPAN

NOTES:

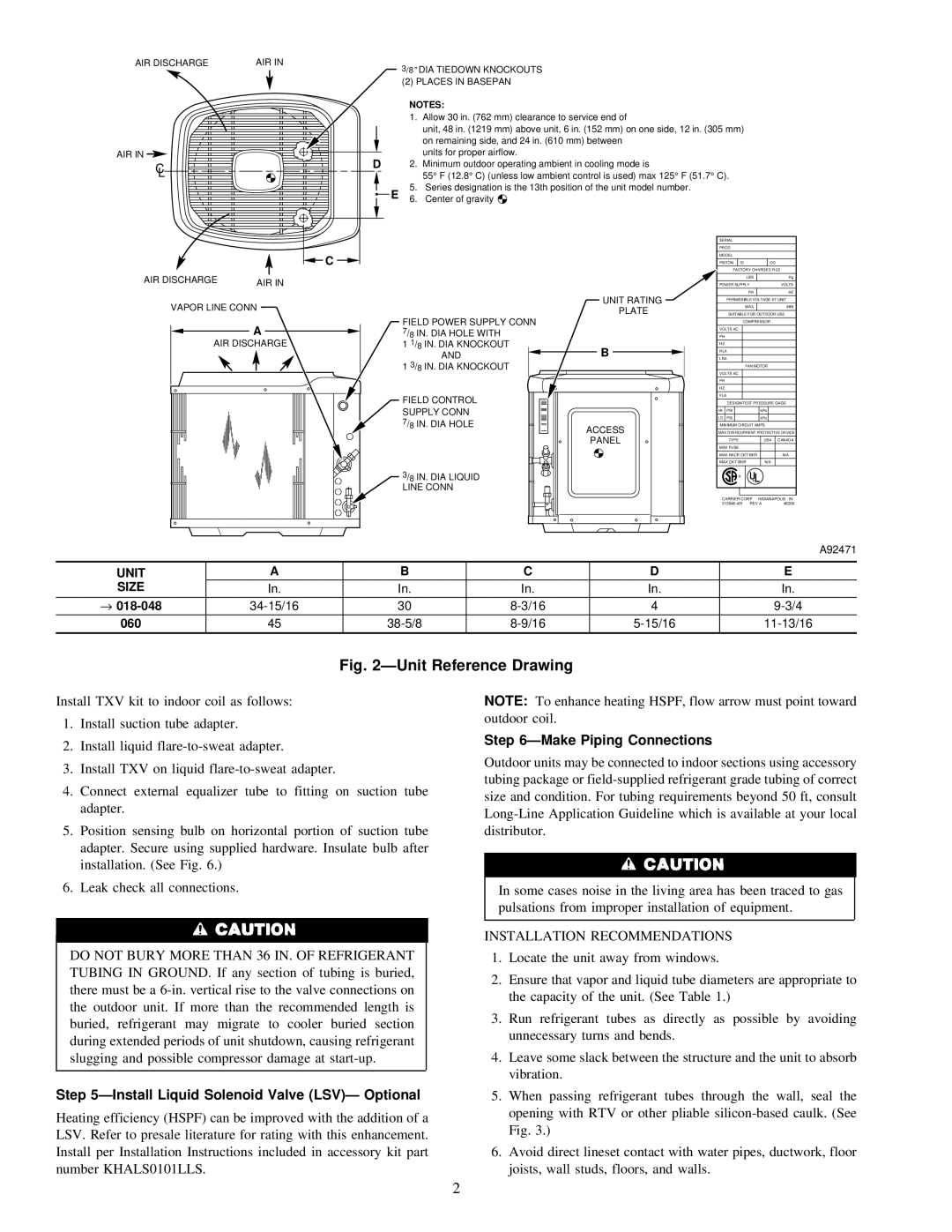

1.Allow 30 in. (762 mm) clearance to service end of

unit, 48 in. (1219 mm) above unit, 6 in. (152 mm) on one side, 12 in. (305 mm) on remaining side, and 24 in. (610 mm) between

units for proper airflow.

D2. Minimum outdoor operating ambient in cooling mode is

|

| 55°F (12.8°C) (unless low ambient control is used) max 125°F (51.7°C). | |

E | 5. | Series designation is the 13th position of the unit model number. | |

6. | Center of gravity | ||

|

![]() C

C ![]()

AIR DISCHARGE | AIR IN |

|

|

|

|

| |

VAPOR LINE CONN |

| UNIT RATING | |

| PLATE | ||

|

|

| |

| A | FIELD POWER SUPPLY CONN |

|

| 7/8 IN. DIA HOLE WITH |

| |

AIR DISCHARGE | 1 1/8 IN. DIA KNOCKOUT | B | |

|

| AND | |

|

| 1 3/8 IN. DIA KNOCKOUT |

|

|

| FIELD CONTROL |

|

|

| SUPPLY CONN |

|

|

| 7/8 IN. DIA HOLE | ACCESS |

|

|

| |

|

|

| PANEL |

|

| 3/8 IN. DIA LIQUID |

|

|

| LINE CONN |

|

SERIAL |

|

|

| |

PROD |

|

|

| |

MODEL |

|

|

| |

PISTON | ID | OD |

| |

| FACTORY CHARGED | |||

|

| LBS |

| Kg |

POWER SUPPLY |

| VOLTS | ||

|

| PH |

| HZ |

| PERMISSIBLE VOLTAGE AT UNIT | |||

|

| MAX |

| MIN |

| SUITABLE FOR OUTDOOR USE | |||

|

| COMPRESSOR |

| |

VOLTS AC |

|

|

| |

PH |

|

|

|

|

HZ |

|

|

|

|

RLA |

|

|

| |

LRA |

|

|

| |

|

| FAN MOTOR |

| |

VOLTS AC |

|

|

| |

PH |

|

|

|

|

HZ |

|

|

|

|

FLA |

|

|

|

|

| DESIGN/TEST PRESSURE GAGE | |||

HI | PSI |

| kPa |

|

LO | PSI |

| kPa |

|

MINIMUM CIRCUIT AMPS |

| |||

MAX OVERCURRENT PROTECTIVE DEVICE | ||||

| TYPE |

| USA | CANADA |

MAX FUSE |

|

|

| |

MAX HACR |

| N/A | ||

MAX | N/A |

| ||

| ® |

|

|

|

|

| ® |

|

|

CARRIER CORP INDIANAPOLIS IN

46206 |

A92471

UNIT | A | B | C | D | E |

SIZE | In. | In. | In. | In. | In. |

|

|

|

|

|

|

→ | 30 | 4 | |||

060 | 45 | ||||

|

|

|

|

|

|

Fig. 2ÐUnit Reference Drawing

Install TXV kit to indoor coil as follows:

1.Install suction tube adapter.

2.Install liquid

3.Install TXV on liquid

4.Connect external equalizer tube to fitting on suction tube adapter.

5.Position sensing bulb on horizontal portion of suction tube adapter. Secure using supplied hardware. Insulate bulb after installation. (See Fig. 6.)

NOTE: To enhance heating HSPF, flow arrow must point toward outdoor coil.

Step 6ÐMake Piping Connections

Outdoor units may be connected to indoor sections using accessory tubing package or

6. Leak check all connections.

DO NOT BURY MORE THAN 36 IN. OF REFRIGERANT TUBING IN GROUND. If any section of tubing is buried, there must be a

Step 5ÐInstall Liquid Solenoid Valve (LSV)Ð Optional

Heating efficiency (HSPF) can be improved with the addition of a LSV. Refer to presale literature for rating with this enhancement. Install per Installation Instructions included in accessory kit part number KHALS0101LLS.

In some cases noise in the living area has been traced to gas pulsations from improper installation of equipment.

INSTALLATION RECOMMENDATIONS

1.Locate the unit away from windows.

2.Ensure that vapor and liquid tube diameters are appropriate to the capacity of the unit. (See Table 1.)

3.Run refrigerant tubes as directly as possible by avoiding unnecessary turns and bends.

4.Leave some slack between the structure and the unit to absorb vibration.

5.When passing refrigerant tubes through the wall, seal the opening with RTV or other pliable

6.Avoid direct lineset contact with water pipes, ductwork, floor joists, wall studs, floors, and walls.

2